Cut seals and bearing washers are essential parts used in a variety of industries to guarantee adequate sealing and efficient machinery and equipment functioning. To suit the unique requirements of various applications, Omsteel Co., a recognised producer specialising in valve and pump components, also manufactures premium, precisely crafted cut seals and bearing washers.

Omsteel Co.produces cut seals and bearing washers that correspond to industry standards and customer needs using cutting-edge manufacturing procedures and cutting-edge equipment. Precision engineering and precise attention to detail are highly valued by the organisation, which ensures that every component is dependable, long-lasting, and capable of working at its best even in challenging circumstances.

Premium materials, such as stainless steel, brass, or other suitable alloys, known for their superior corrosion resistance and mechanical capabilities, are used to create the cut seals and bearing washers produced by Omsteel Co. The materials used in sealing and bearing applications are carefully chosen to endure the extreme temperatures, pressures, and conditions.

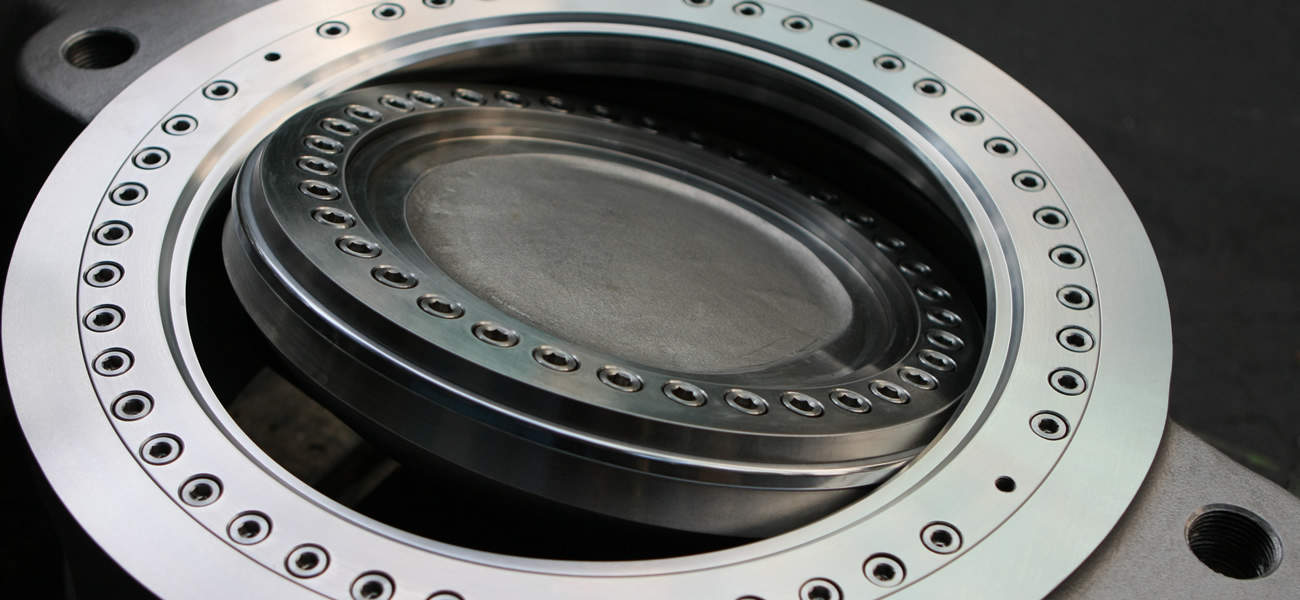

Omsteel Co. provides a wide selection of cut seals and bearing washers that are intended to deliver reliable bearing support and effective sealing. These parts are essential for keeping machinery and equipment properly lubricated and for preventing leaks. The cut seals and bearing washers from Omsteel Co. provide dependable performance and long service life, whether they are used to ensure fluid containment in hydraulic systems or to lessen friction and wear in rotating machinery.

| Component | Material | Operating Temperature Range | Pressure Rating | Maximum Load Capacity | Customization Options |

|---|---|---|---|---|---|

| O-Rings | Premium-grade, elastomers | -40°C to +200°C | Up to 5000 psi | Dependent on size | Size, material, hardness |

| Gaskets | Rubber, cork, fiber | -30°C to +150°C | Up to 1500 psi | Dependent on size | Size, material, shape |

| V-Rings | Premium-grade, elastomers | -40°C to +150°C | Up to 3000 psi | Dependent on size | Size, material |

| Oil Seals | Nitrile, fluoroelastomer, polyacrylate | -40°C to +200°C | Up to 5000 psi | Dependent on size | Size, material, lip |

| Thrust Washers | Self-lubricating materials (e.g., PTFE, bronze) | -50°C to +150°C | Up to 2000 psi | Dependent on size | Size, material, thickness |

| Spherical Washers | Stainless steel, brass, alloy | -50°C to +250°C | Up to 5000 psi | Dependent on size | Size, material, curvature |

Our Cut Seals/Bearing washers are used in various extensive applications across a wide range of industries.

SS431, 17-4 PH, Duplex 4A, Duplex 5A, XM19 Monel K500, K400, SS316

Omsteel Co. supply our Cut Seals/Bearing washers to countries like : The United States

Europe

Middle East

Africa

and more

Feel free to contact us any time. we will get back to you as soon as we can!

Quality is the bedrock of our business. We are an ISO 9001:2008 Certified Company that caters to a cross-section of industry; Om Steel has emerged as a reliable supplier to international clients as per customization. Undertakings as well as start-up enterprises for more than a decade. We consistently meet our customers’ needs with a sharp focus on product excellence, cost optimization and timely delivery.