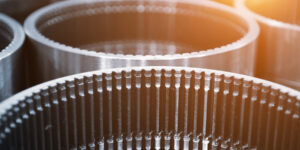

Ring rolling is a specialized metal forming process used to manufacture seamless rings of various sizes and shapes. It involves shaping a metal workpiece by subjecting it to controlled deformation between two rotating dies. The dies exert pressure on the workpiece, causing it to deform and take on the desired ring shape.

During the ring rolling process, the workpiece is typically heated to a specific temperature to improve its plasticity and reduce the forces required for deformation. This temperature is carefully controlled to ensure proper shaping and prevent material defects.

Ring rolling finds applications in various industries, including aerospace, automotive, energy, and industrial sectors. Typical products produced by ring rolling include seamless rolled rings, bearing races, flanges, gears, and other components that require strength, durability, and precision.

Overall, ring rolling is a versatile and efficient manufacturing process that allows for the production of high-quality seamless rings with excellent mechanical properties and complex geometries.

Omsteel Co. is proud of its dedication to quality, accuracy, and client satisfaction. We work hard to earn your trust as your go-to source for all things ring rolling. We strive to go above and beyond your expectations by giving you ring rollings that are of the best quality and performance, and we accomplish this through our sophisticated manufacturing capabilities, rigorous quality control procedures, and prompt delivery. When you need ring rollings that will improve your industrial processes, choose Omsteel Co.

| Specifications | Value |

|---|---|

| Material | Stainless Steel (e.g., SS316) |

| Tensile Strength | 75,000 – 95,000 psi |

| Yield Strength | 30,000 – 45,000 psi |

| Hardness | 75 – 90 HRB |

| Impact Strength | Varies |

| Fatigue Strength | Varies |

| Elongation | 15 – 25% |

| Modulus of Elasticity | 28 x 10^6 psi |

| Poisson’s Ratio | 0.3 |

Our Ring Rollings are used in various extensive applications across a wide range of industries.

Omsteel Co. supply our Valve kits to countries like :

The United States

Europe

Middle East

Africa

and more

SS431, 17-4 PH, Duplex 4A, Duplex 5A, XM19 Monel K500, K400, SS316

Feel free to contact us any time. we will get back to you as soon as we can!

Quality is the bedrock of our business. We are an ISO 9001:2008 Certified Company that caters to a cross-section of industry; Om Steel has emerged as a reliable supplier to international clients as per customization. Undertakings as well as start-up enterprises for more than a decade. We consistently meet our customers’ needs with a sharp focus on product excellence, cost optimization and timely delivery.

WhatsApp us