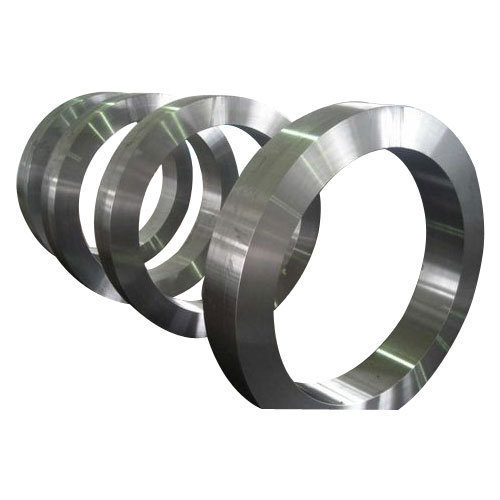

Forged rings are precision-crafted components offered by Omsteel Co., renowned for their exceptional quality and performance. These rings are manufactured using advanced forging techniques and meticulous attention to detail, ensuring superior strength, durability, and reliability.

Omsteel Co. specializes in producing forged rings that are engineered to withstand the most demanding applications. These rings are created from high-quality materials, such as steel or other suitable alloys, carefully selected for their excellent mechanical properties and resistance to wear and deformation.

The forging process employed by Omsteel Co. ensures that the rings possess a refined grain structure, enhancing their mechanical integrity and resistance to fatigue and impact. With their robust construction, forged rings are capable of withstanding heavy loads, extreme temperatures, and harsh operating conditions, making them ideal for critical applications in industries such as aerospace, oil and gas, and power generation.

The precision machining of forged rings results in tight tolerances, smooth surfaces, and accurate dimensions. This guarantees optimal fitment, seamless integration, and reliable performance in various equipment and machinery. Whether used in gears, bearings, or other rotating components, forged rings from Omsteel Co. exhibit exceptional reliability and longevity.

By choosing Omsteel Co.’s forged rings, customers can have confidence in the qual

Omsteel and durability of their components. These precision-crafted rings are designed to meet industry standards and exceed customer expectations, delivering reliable performance and contributing to the overall efficiency and effectiveness of their applications.

These forged rings are produced through a seamless rolling process, where a metal billet is pierced to form a hollow ring shape. Seamless rolled rings offer excellent strength and integrity due to their uninterrupted grain flow.

Welded rings are formed by joining the ends of a metal strip or plate through welding. This process allows for the creation of large-diameter rings or rings with custom shapes that may be challenging to produce through seamless rolling.

Upset rings are forged by compressing a heated cylindrical blank between two dies, resulting in an increase in diameter and reduction in height. These rings are commonly used in applications where high strength and resistance to deformation are required.

Contoured rings are forged with specific shapes or profiles to suit unique application requirements. They can have features such as grooves, flanges, or irregular shapes to fulfill specialized functions in various industries.

These forged rings are made from carbon steel, which offers high strength, durability, and good machinability. Carbon steel rings are widely used in industries such as oil and gas, automotive, and machinery manufacturing.

Alloy steel rings are forged from steel that has been alloyed with other elements to enhance specific properties such as strength, hardness, and corrosion resistance. These rings are commonly used in applications requiring higher performance and resistance to extreme conditions.

Stainless steel rings are forged from corrosion-resistant steel alloys, providing excellent resistance to rust, oxidation, and chemical corrosion. They are frequently used in industries such as food processing, chemical, and marine applications.

Forged titanium rings offer a combination of high strength, low weight, and excellent corrosion resistance. They find applications in aerospace, medical, and chemical industries where these properties are critical.

Omsteel Co.uses premium-grade materials for forging rings, such as carbon steel, alloy steel, stainless steel, and other specialized alloys. The selection of materials depends on the specific requirements of the application and the desired properties of the final product.

Omsteel Co.provides flexibility in terms of dimensions and sizes. They can manufacture forged rings in various diameters, heights, and weights to meet the unique specifications of their customers. Whether it’s a small ring or a large one, Omsteel Co.can accommodate different size requirements.

Omsteel Co.employs advanced forging techniques to ensure precise shaping and forming of the rings. They utilize state-of-the-art machinery and skilled craftsmen to achieve accurate dimensions, smooth surfaces, and consistent quality throughout the forging process.

The forging process enhances the mechanical properties of the rings, resulting in superior strength and durability. Forged rings from Omsteel Co.exhibit excellent resistance to fatigue, impact, and wear, making them suitable for demanding applications that require reliable and long-lasting components.

Omsteel Co.pays special attention to the metallurgical integrity of their forged rings. Through controlled heating, forging, and cooling processes, they achieve a refined microstructure with improved mechanical properties. This ensures the rings have excellent structural integrity, high toughness, and resistance to cracking or failure.

Omsteel Co.’s forged rings find applications in various industries, including aerospace, oil and gas, automotive, power generation, mining, and more. They can be used for critical components such as bearing races, flanges, gears, cylinders, valves, and other heavy-duty applications that require reliable and high-performance rings.

Omsteel Co.maintains stringent quality control measures to ensure that their forged rings meet the highest standards. They perform thorough inspections and tests, including dimensional checks, visual inspections, non-destructive testing, and material analysis, to verify the quality and integrity of each ring.

Omsteel Co.offers customization options to meet specific customer requirements. They can provide additional machining services to achieve precise tolerances, specialized surface finishes, or add features like grooves or holes to the forged rings.

Omsteel Co.is committed to delivering forged rings on time, ensuring that customers’ production schedules are not disrupted. They have efficient manufacturing processes and logistics management to meet delivery deadlines and maintain customer satisfaction.

With their experienced engineering team and extensive knowledge in forging technologies, Omsteel Co.can provide technical support and collaborate with customers to optimize designs, recommend suitable materials, and ensure the successful implementation of forged rings in their applications.

The United States

Europe

Middle East

Africa