Maximizing Performance with Precision Machined Components

In today’s fast-paced world, precision machined components play a crucial role in various industries. From aerospace to automotive, these components are the unsung heroes behind the smooth functioning of machinery and equipment. Let’s take a closer look at what makes precision machined components. So essential and how they contribute to maximizing performance.

Overview of Precision Machined Components

Precision-machined components are parts that are crafted with extreme accuracy and attention to detail. They are manufactured using advanced techniques. To ensure they meet exact specifications and perform optimally in their intended applications.

Key Features of Precision Machined Components

Machined components are known for their outstanding quality. Made with care to ensure they work perfectly. They are crafted using advanced techniques.

1. Exceptional Quality

Precision-machined components are synonymous with quality. Every component is subjected to rigorous quality control processes. To guarantee that the highest requirements are met.

2. Advanced Manufacturing Techniques

These components are crafted using state-of-the-art manufacturing techniques such as CNC machining, milling, and turning. These advanced methods allow for intricate designs and tight tolerances.

3. Customization Options

One of the significant advantages of Machined components is their ability to be customized to meet specific requirements. Regardless of the material, shape, or size being unique.One of the significant advantages of Machined components is their ability to be customized to meet specific requirements. Regardless of the material, shape, or size being unique.

4. Reliability and Longevity

Due to their precise craftsmanship and high-quality materials, precision-machined components offer unparalleled reliability and longevity. They can withstand harsh conditions, heavy loads, and constant use without compromising performance.

5. Industry Compliance

Machined components adhere to strict industry standards and regulations to ensure they meet safety and performance requirements. In aerospace, medical, or automotive, these components are designed to comply with specific industry guidelines, providing peace of mind to manufacturers and end-users alike.

Types of precision machined components

Precision-machined components come in various shapes and sizes, each serving a specific purpose in different industries. Some common types include:

1. Shafts

Shafts are cylindrical rods that transmit power in machines, engines, and other mechanical systems. They come in different lengths and diameters, depending on the application, and are often precision machined for optimal performance.

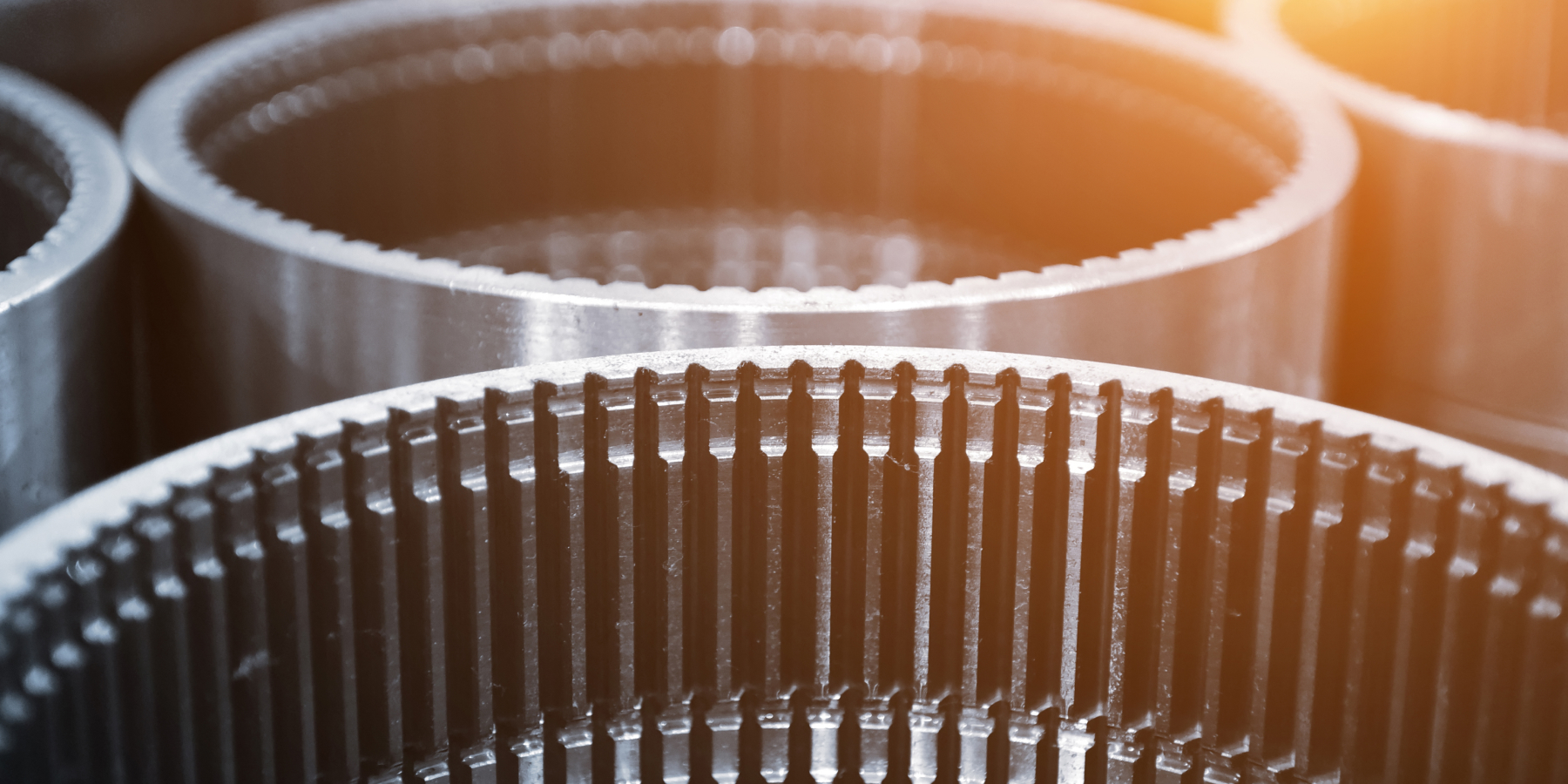

2. Gears

Gears are toothed wheels that mesh together to transmit motion and power between rotating shafts. Precision machining ensures the teeth are accurately shaped and spaced for smooth operation and minimal wear.

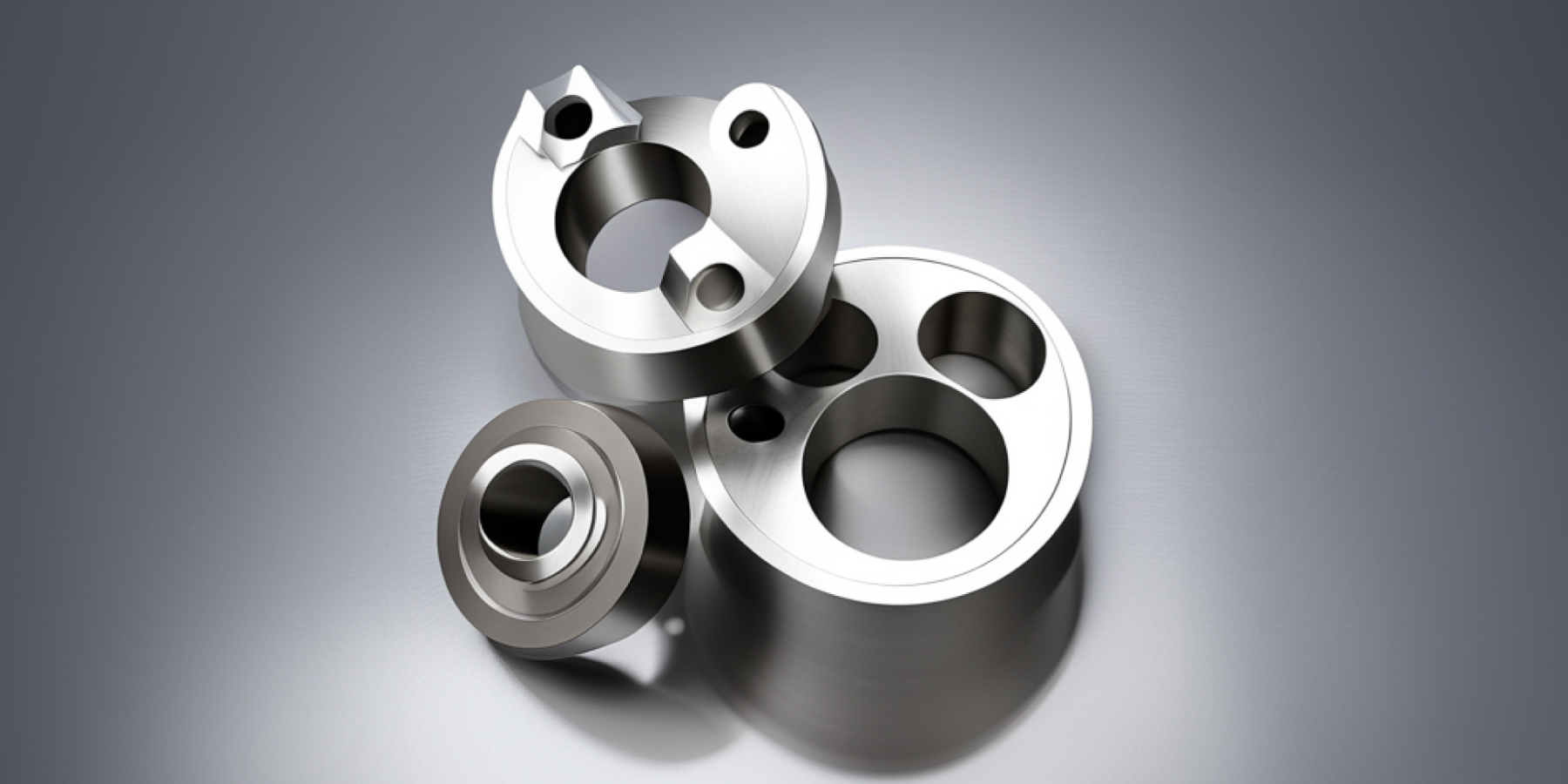

3. Bearings

Bearings are mechanical components that reduce friction between moving parts and support rotating or oscillating shafts. Precision machining ensures the inner and outer surfaces of bearings are perfectly smooth and aligned for maximum efficiency.

4. Pistons

Pistons are cylindrical components that move back and forth inside cylinders to convert pressure into mechanical energy. Precision machining ensures the piston’s dimensions and surface finish are precisely controlled for optimal sealing and performance.

5. Valves

Valves are devices that control the flow of fluids or gases within a system by opening, closing, or redirecting passages. Precision machining ensures the valve components fit together seamlessly and operate smoothly, preventing leaks and ensuring precise control.

Importance of Precision Machined Components in Industries

Precision-machined components are very important in industries. They help machines work well. This means less trouble and more productivity. They are needed in many industries like planes, cars, and hospitals.

Specifications of Precision Machined Components

| Component | Material | Dimensions | Tolerance | Surface Finish |

|---|---|---|---|---|

| Shaft | Stainless Steel | 50mm x 200mm | ±0.005mm | Ra 0.4 |

| Gear | Alloy Steel | Module 3 | ±0.01mm | Ra 0.8 |

| Bearing | Brass | Inner Dia: 25mm | ±0.02mm | – |

| Coupling | Aluminum | 100mm x 100mm | ±0.02mm | Ra 0.6 |

| Piston | Carbon Steel | Diameter 75mm | ±0.01mm | – |

| Valve Body | Stainless Steel | DN50 | ±0.1mm | Ra 0.2 |

| Housing | Cast Iron | 200mm x 150mm | ±0.1mm | – |

| Fitting | Brass | 1/2″ NPT | ±0.05mm | – |

| Spindle | Tool Steel | Length: 300mm | ±0.02mm | Ra 0.4 |

| Cylinder | Aluminum | Diameter 80mm | ±0.05mm | – |

Industrial Applications of Precision Machined Components

Machined components are widely used in industries for:

1. Aerospace : Crafting aircraft engines and precise navigation systems.

2. Automotive : Ensure the smooth functioning of engine parts and transmission systems in vehicles.

3. Medical : They play a vital role in producing accurate surgical instruments and medical devices.

4. Electronics : Machined components are essential for creating small, intricate parts in electronic devices.

5. Oil and Gas : In this industry, they’re integral for manufacturing reliable drilling equipment and valves for pipelines.

Recommended Precision Machined Components Suppliers

Looking for precision machined components? Consider Omsteel. They are a trusted supplier known for their high-quality products and reliable service. With advanced manufacturing capabilities, they can meet your specific requirements with precision. Choose Omsteel for dependable solutions that enhance your productivity and competitiveness.

In conclusion, machined components play a vital role in industries worldwide. From shafts to gears, these components serve diverse applications, driving efficiency and innovation. To source high-quality precision machined components, consider Omsteel as your trusted supplier. Their commitment to excellence and industry-leading capabilities make them the ideal choice in today’s market.

In conclusion, machined components play a vital role in industries worldwide. From shafts to gears, these components serve diverse applications, driving efficiency and innovation. To source high-quality precision machined components, consider Omsteel as your trusted supplier. Their commitment to excellence and industry-leading capabilities make them the ideal choice in today’s market.