Everything You Need to Know About Stainless Steel Rings

Stainless steel rings have gained immense popularity across various sectors, from fashion jewelry to industrial applications. Renowned for their durability, corrosion resistance, and appealing aesthetics, these rings are a top choice for many. This comprehensive guide delves into the qualities of stainless steel rings, their manufacturing process, and the importance of selecting a reliable manufacturer.

The Benefits of Stainless Steel Rings

Durability and Strength

Stainless steel rings are known for their exceptional strength and durability. Unlike other metals, they maintain their shape and structural integrity even with daily wear and tear. This resilience makes them ideal for both fashion jewelry and industrial applications.

Corrosion Resistance

A standout feature of stainless steel is its superior corrosion resistance. This property is particularly valuable in environments where the rings may be exposed to moisture, chemicals, or extreme temperatures, ensuring longevity and reliability.

Low Maintenance

One of the major advantages of stainless steel rings is their low maintenance. They do not tarnish or rust and can be easily cleaned with a simple wipe. This makes them an attractive option for busy individuals and professionals who prefer low-maintenance accessories.

Hypoallergenic Properties

Many people have allergies to metals like nickel, commonly used in jewelry. Stainless steel, especially surgical-grade varieties, is hypoallergenic, making it safe for individuals with sensitive skin.

Cost-Effective

Compared to precious metals like gold or platinum, stainless steel is much more affordable. Despite its lower cost, it offers a luxurious appearance and exceptional durability, making it a cost-effective choice.

The Manufacturing Process of Stainless Steel Rings

Material Selection

The manufacturing process starts with the selection of high-quality stainless steel. Different grades of stainless steel are chosen based on the application. For example, 316L stainless steel is popular in jewelry due to its superior corrosion resistance and hypoallergenic properties.

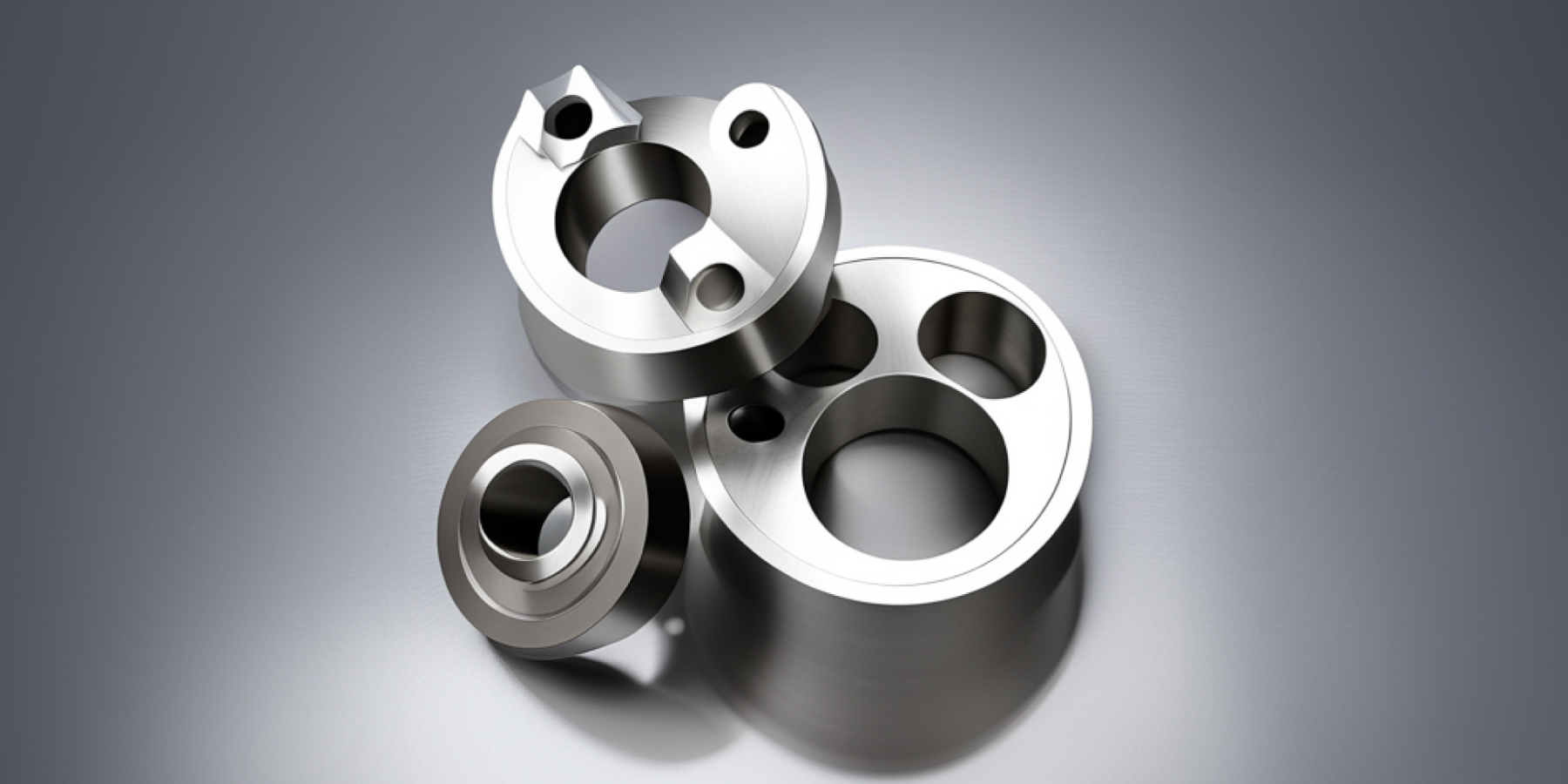

Cutting and Shaping

The selected stainless steel is cut into the desired shape using techniques such as laser cutting or water jet cutting. Precision in this step is crucial to ensure the ring meets exact specifications.

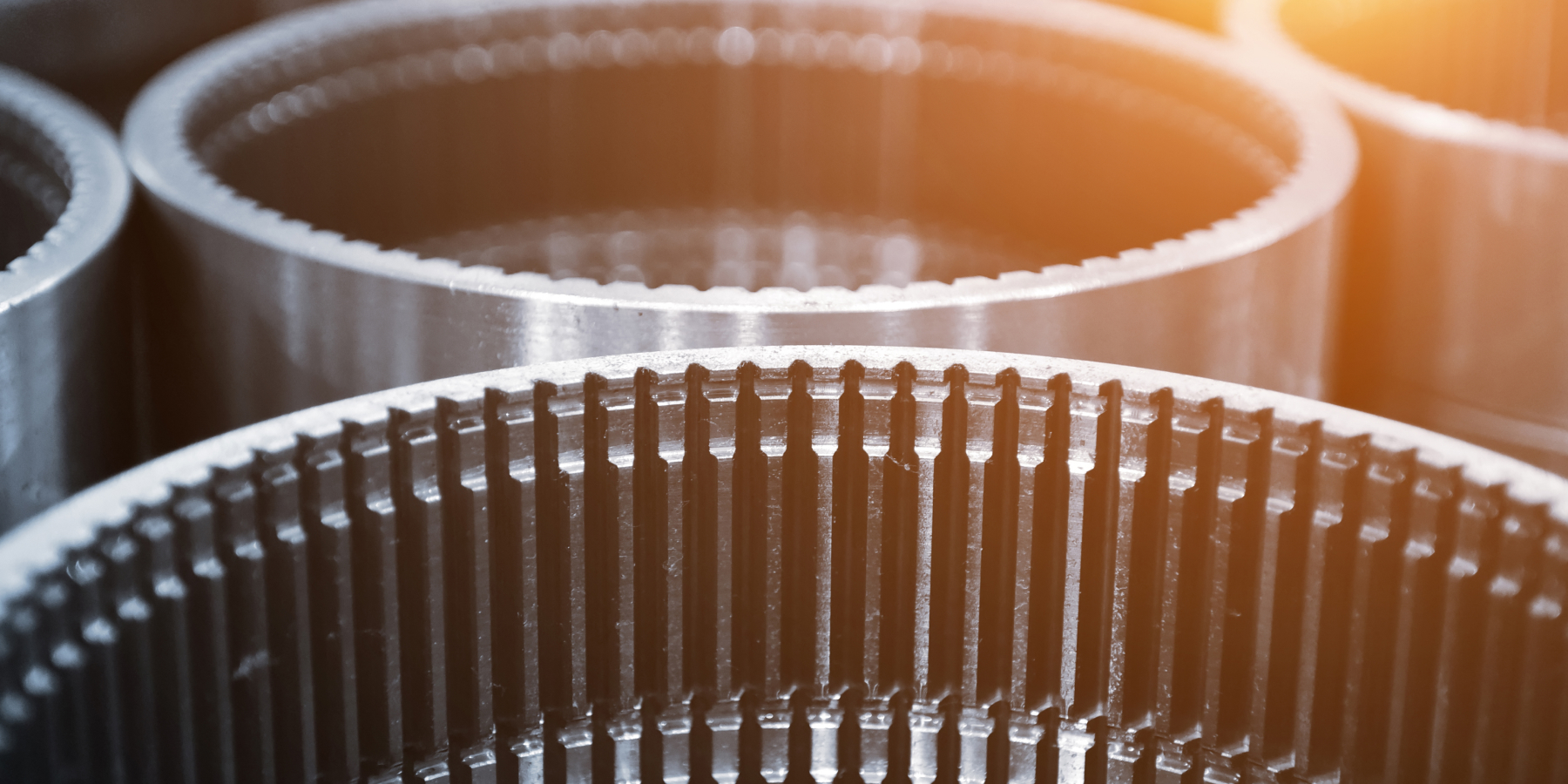

Forming

Once cut, the steel is formed into a ring shape through processes like forging, casting, or machining. Each method has its advantages, with forging and casting is preferred for applications requiring high strength.

Polishing and Finishing

After forming, the ring undergoes polishing and finishing to achieve a smooth surface and desired appearance. This step involves grinding, buffing, and sometimes electroplating to enhance the ring’s look and feel.

Quality Control

The final step in the manufacturing process is quality control. Each ring is meticulously inspected for any defects or imperfections to ensure it meets the required standards.

Choosing the Right Stainless Steel Ring Manufacturer

Experience and Expertise

When selecting a manufacturer, consider their experience and expertise in producing stainless steel rings. An established manufacturer with a proven track record of delivering high-quality products is essential.

Customization Options

Look for manufacturers that offer customization options. Whether you need rings in specific sizes, shapes, or designs, a manufacturer with customization capabilities can meet your unique requirements.

Quality Assurance

Ensure that the manufacturer follows strict quality assurance protocols. This includes using high-grade materials, precise manufacturing processes, and thorough quality control checks to guarantee the highest quality.

Customer Support

Reliable customer support is crucial. Choose a manufacturer that provides excellent customer service, addressing any queries or concerns promptly and effectively.

Competitive Pricing

While quality should never be compromised, it’s also important to find a manufacturer that offers competitive pricing. This ensures you get the best value for your investment.

Conclusion

Stainless steel rings offer a perfect blend of durability, aesthetic appeal, and affordability. Whether for jewelry or industrial use, these rings are a practical and stylish choice. By understanding the benefits and manufacturing process of stainless steel rings, and knowing what to look for in a manufacturer, you can make an informed decision that meets your needs. Choose a reputable stainless steel ring manufacturer to ensure you receive high-quality, reliable products that stand the test of time.