Precision Engineering with VMC Machined Components

Vertical Machining Centers (VMC) play a pivotal role in producing high-precision parts essential for various industries. VMC machined components are renowned for their accuracy, durability, and efficiency, making them indispensable in sectors such as aerospace, automotive, and medical devices. In this blog, we will delve into the world of VMC machined components, exploring the importance of VMC parts, components, and machine parts, and highlighting why precision engineering with VMC is crucial for achieving top-notch quality.

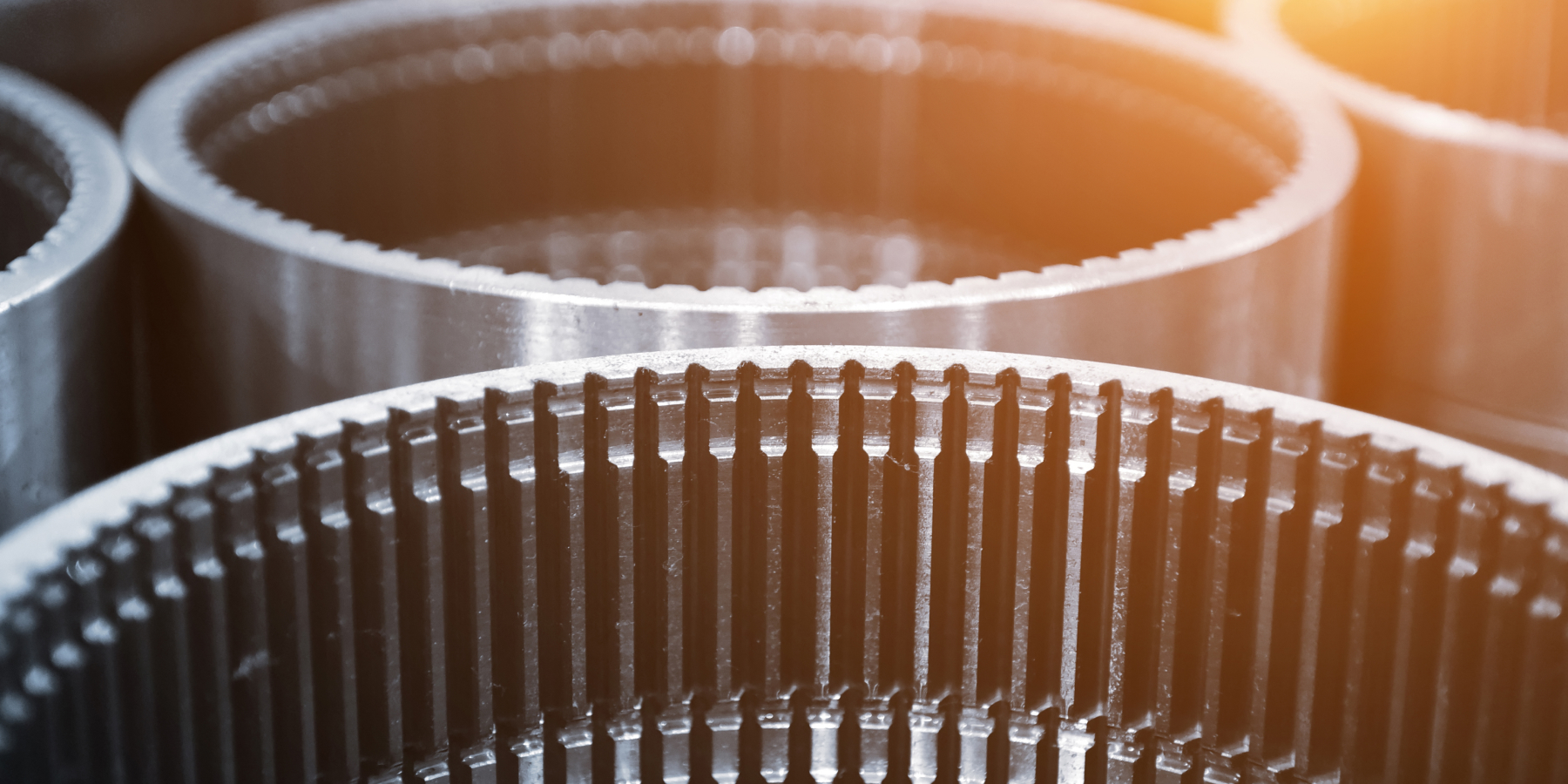

Understanding VMC Machined Components

VMC Machined Components are parts produced using Vertical Machining Centers, which are computer-controlled machines designed for precision cutting, drilling, and shaping of materials. These components are integral to various machinery and equipment, ensuring optimal performance and reliability.

Key Characteristics of VMC Machined Components

1. High Precision

VMC machines operate with exceptional accuracy, often within microns, ensuring that each component meets stringent specifications.

2. Versatility

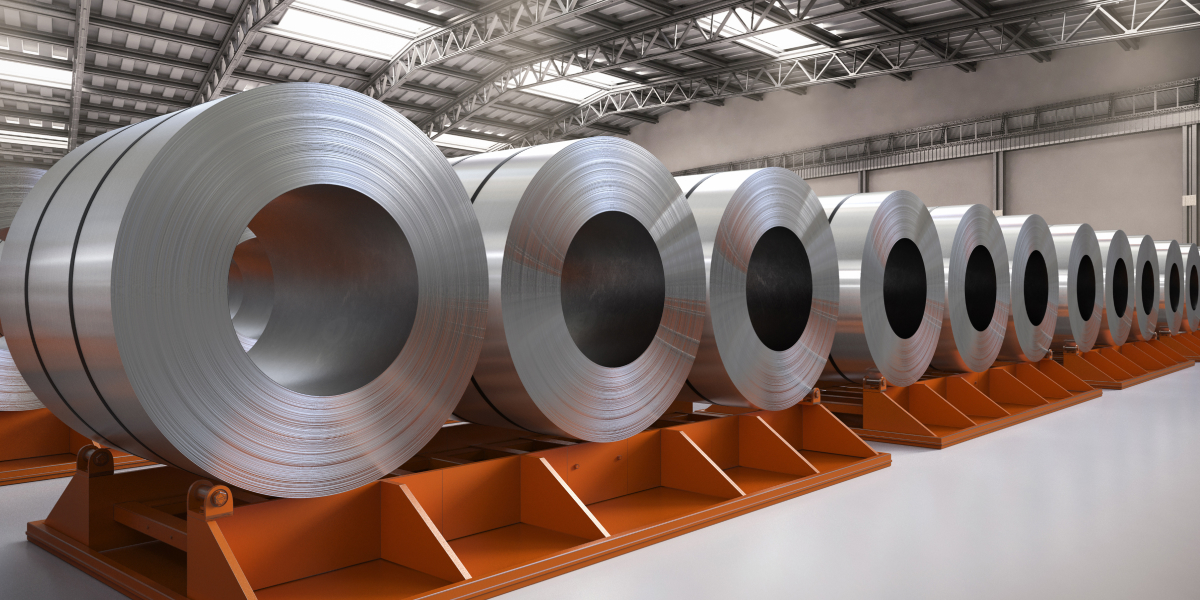

VMCs can handle a wide range of materials, including metals, plastics, and composites, making them suitable for diverse applications.

3. Efficiency

The automation and advanced controls of VMCs streamline the manufacturing process, reducing production time and costs

The Importance of VMC Parts

VMC Parts are the individual elements that make up the Vertical Machining Centers themselves. These parts are critical for the machine’s operation and overall performance.

Essential VMC Parts Include

Spindle: The heart of the VMC is responsible for rotating the cutting tool at high speeds.

Tool Changer: Automatically swaps out tools as needed, enhancing efficiency and reducing downtime.

Control Panel: The interface for operators to program and control the machine.

Cooling System: Maintains optimal temperatures, preventing overheating and ensuring consistent performance.

Tool Changer: Automatically swaps out tools as needed, enhancing efficiency and reducing downtime.

Control Panel: The interface for operators to program and control the machine.

Cooling System: Maintains optimal temperatures, preventing overheating and ensuring consistent performance.

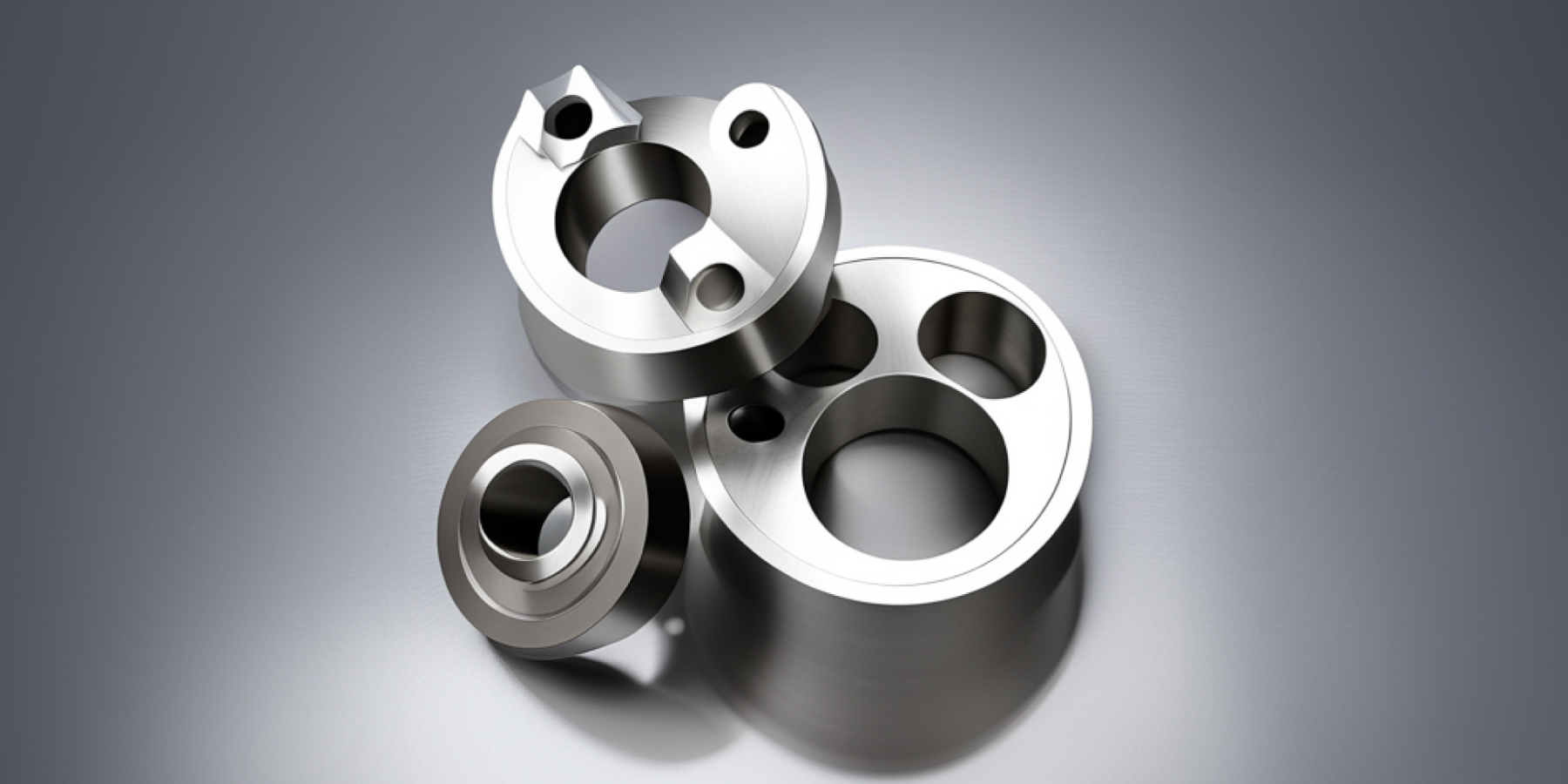

Exploring VMC Components

VMC Components refer to the broader assembly of parts that work together within a VMC to perform machining operations. These components are designed to withstand high-stress environments and deliver precise results.

Key VMC Components Include

Linear Guides and Bearings: Ensure smooth and precise movement of the machine’s axes.

Workholding Devices: Secure the workpiece in place during machining, crucial for accuracy and safety.

Cutting Tools: Various tools such as end mills, drills, and taps that perform the actual cutting and shaping of materials.

Workholding Devices: Secure the workpiece in place during machining, crucial for accuracy and safety.

Cutting Tools: Various tools such as end mills, drills, and taps that perform the actual cutting and shaping of materials.

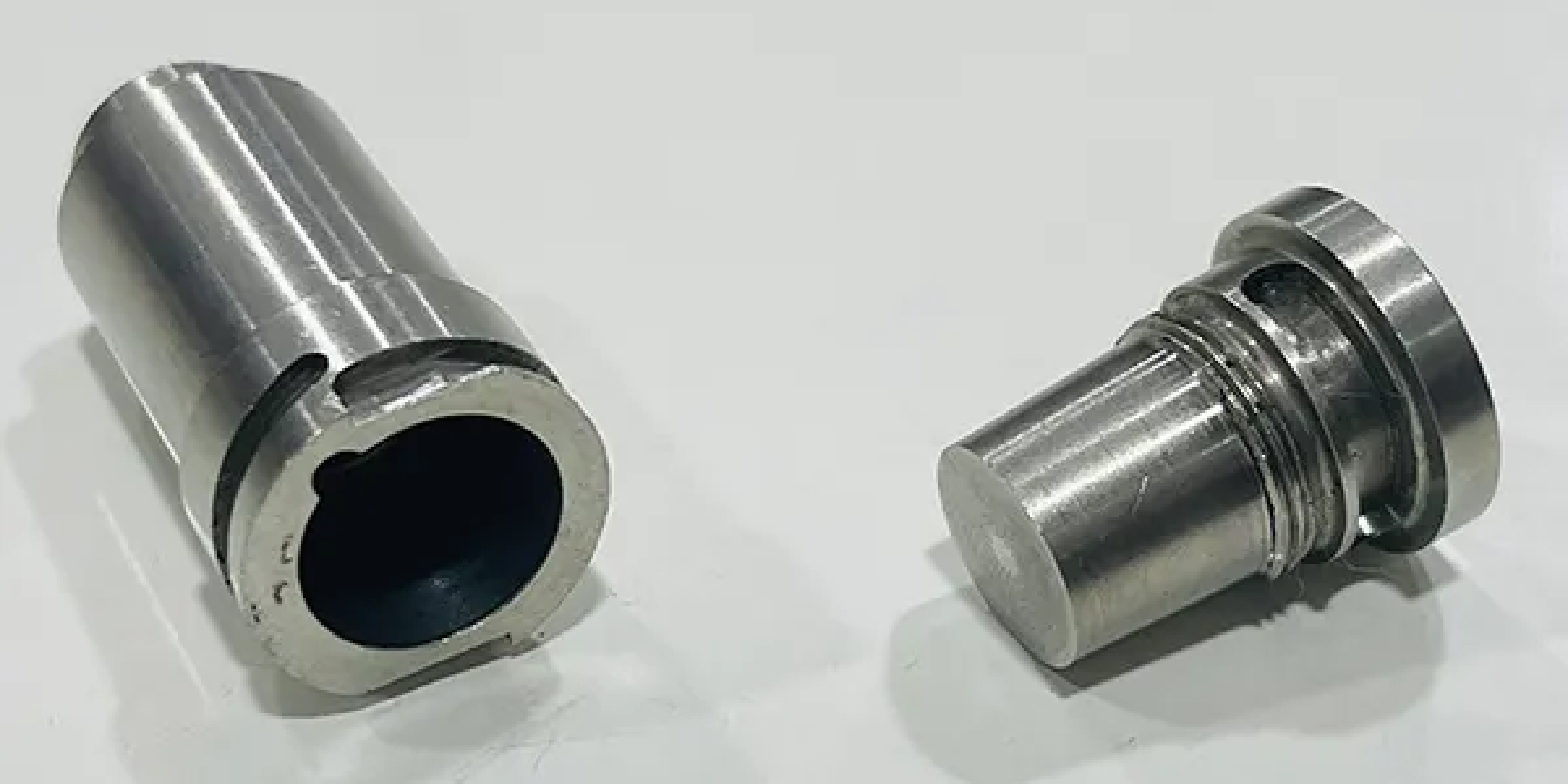

VMC Machine Parts and Their Role

VMC Machine Parts encompass both the mechanical and electronic elements that enable the VMC to function correctly. These parts are engineered for durability and precision, ensuring the machine’s longevity and performance

Critical VMC Machine Parts

Servo Motors: Provide precise control over the machine’s movements.

Ball Screws: Convert rotational motion into linear motion with high accuracy.

Encoders: Measure the position of the machine’s axes, ensuring precise movement and positioning.

Hydraulic Systems: Control various functions, including tool changes and workpiece clamping.

Ball Screws: Convert rotational motion into linear motion with high accuracy.

Encoders: Measure the position of the machine’s axes, ensuring precise movement and positioning.

Hydraulic Systems: Control various functions, including tool changes and workpiece clamping.

The Value of Precision Engineering with VMC

Precision engineering with VMC machined components is vital for industries that demand high-quality, reliable parts. By understanding the importance of VMC parts, components, and machine parts, manufacturers can optimize their processes, reduce downtime, and produce superior products. Investing in VMC technology and maintaining it properly ensures that businesses stay competitive in a market that increasingly values precision and efficiency.

Incorporating VMC-machined components into your manufacturing processes can significantly enhance your production capabilities, delivering parts that meet the highest standards of precision and durability. Whether you’re in aerospace, automotive, or any other industry, leveraging the power of VMCs will drive your success and innovation forward.

Incorporating VMC-machined components into your manufacturing processes can significantly enhance your production capabilities, delivering parts that meet the highest standards of precision and durability. Whether you’re in aerospace, automotive, or any other industry, leveraging the power of VMCs will drive your success and innovation forward.