A Guide to VMC Components and Their Industrial Applications

Regarding high-precision manufacturing, Vertical Machining Centers (VMC) are game-changers. But what drives the performance of these machines? It’s all about the VMC components. From boosting accuracy to handling high-stress operations, the right components make all the difference. Let’s dive into the world of VMC machined components and discover how they can transform industrial applications.

Why Do VMC Components Matter?

In industries where precision equals performance, every piece of the machine matters. VMC components—spindles, ball screws, tool holders, and more—are the building blocks of a well-oiled operation. The right parts don’t just ensure smooth production; they reduce downtime and increase efficiency. Whether you’re in automotive, aerospace, or medical manufacturing, the power of these components is undeniable.

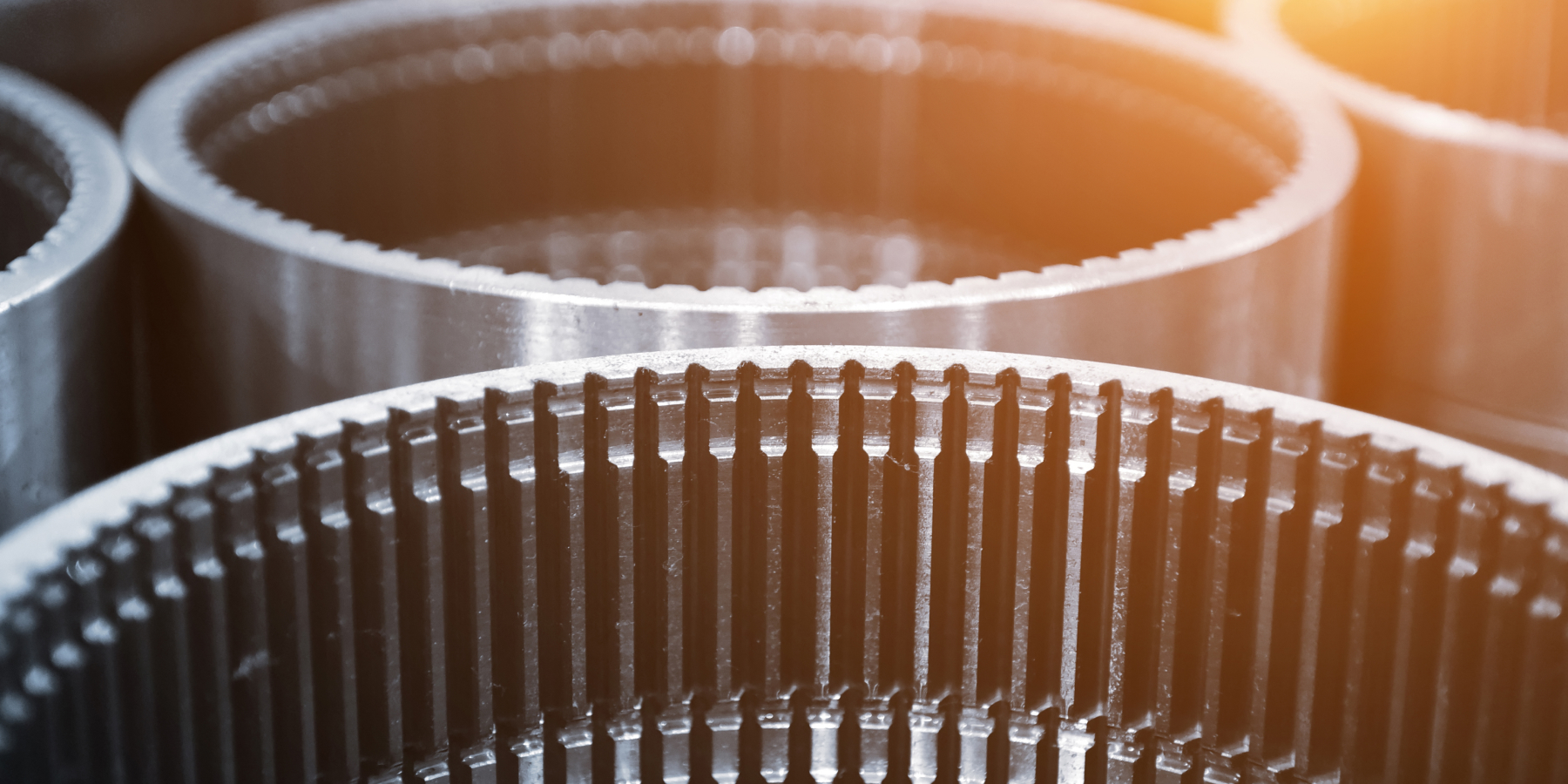

Top VMC Components and Their Roles

- Spindle: The workhorse of the VMC machine, ensuring fast, accurate rotations for cutting tools.

- Tool Holders: Secures the cutting tools with precision, ensuring they remain stable during the process.

- Control System: Offers seamless command over the machine, giving operators the flexibility to adjust machining specs on the go.

- Ball Screws: These unsung heroes keep everything moving smoothly, ensuring each cut is precise and error-free.

- Coolant Systems: Maintain the perfect temperature, safeguarding components from overheating and wear.

Applications of VMC Components

VMC components are indispensable across a range of high-demand industries, ensuring precision and longevity in everything from cars to medical devices. Let’s look at how these parts play key roles:

- Automotive: Engine parts, transmission components, and even chassis elements rely on VMC components for precise shaping and assembly.

- Aerospace: Manufacturing turbine blades, wing parts, and other aircraft components with high precision is critical for safety and performance.

- Medical Equipment: Surgical tools, implants, and other medical-grade devices need the accuracy and reliability only VMC machines can offer.

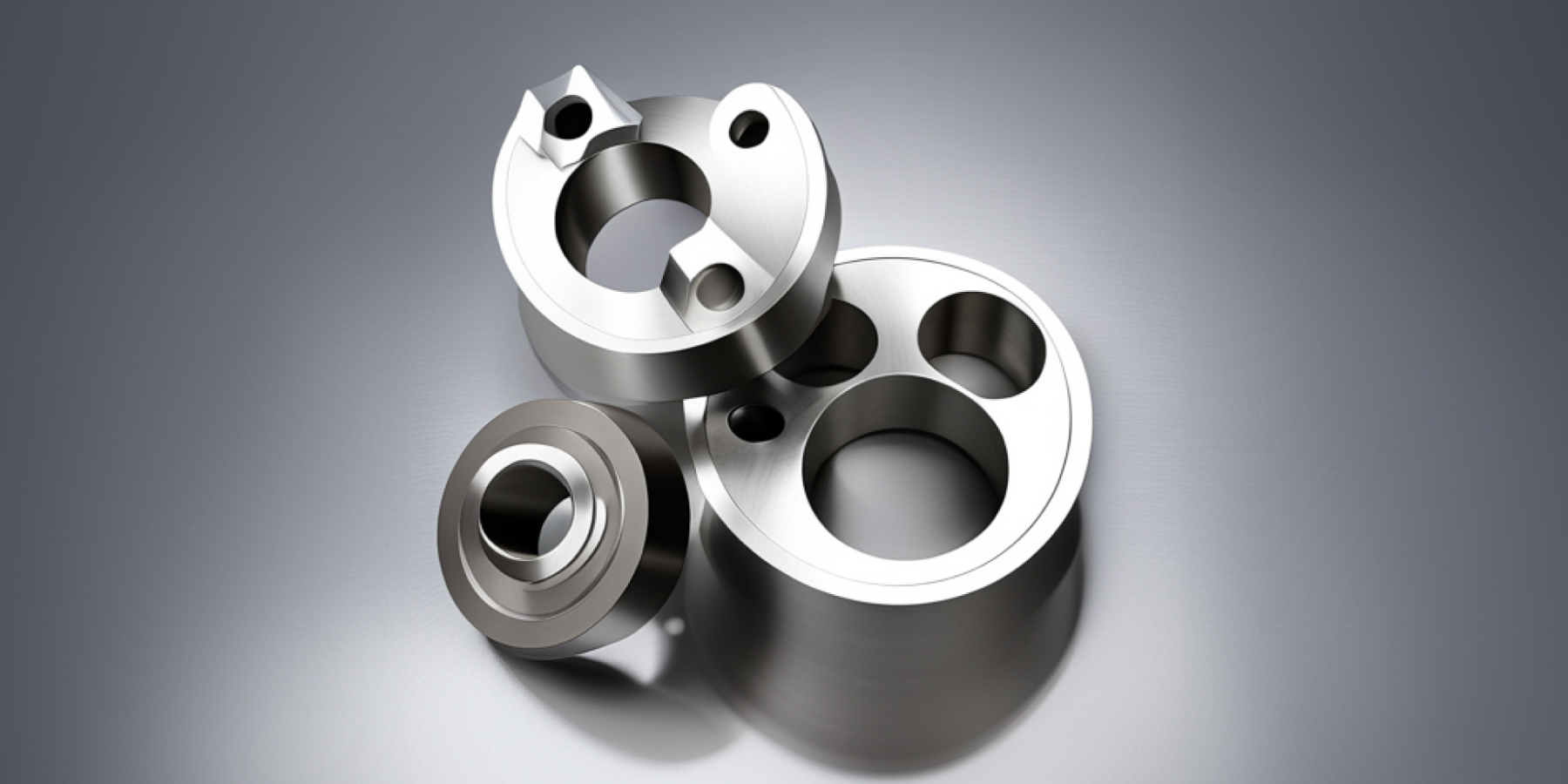

How to Choose the Right VMC Components

Finding the right VMC components manufacturer is essential. Quality VMC parts will directly impact the accuracy of your machines, reduce maintenance costs, and extend equipment lifespan. Here’s what to look for:

- Material Durability: High-grade materials ensure that parts can withstand pressure and high temperatures.

- Precision Engineering: Look for suppliers that offer components with tight tolerances to ensure flawless performance.

- Ease of Maintenance: Components that are easy to replace and maintain will save you headaches in the long run.

VMC Machined Products

From tiny screws to complex assemblies, VMC machined products can be customized to meet the high standards of every industry. Whether you’re working with metals, plastics, or composites, VMC machines guarantee exceptional results, every time.

Maximize Efficiency with High-Quality VMC Components

At the end of the day, your machinery is only as good as its parts. Investing in high-quality VMC components will save you time, money, and stress while ensuring your products meet top industry standards. Whether you’re in the automotive sector or manufacturing medical devices, choosing the right VMC components manufacturer can take your operations to the next level.

FAQs

Precision, durability, and efficiency—VMC components ensure high-quality machining across various industries.

Look for manufacturers with a reputation for delivering high-precision, durable parts that meet your industry’s unique demands.

VMC machined components are widely used in automotive, aerospace, and medical equipment manufacturing, where precision is critical.