A Professional Overview for Maximizing Efficiency with Cut Seals and Bearing Washers

Understanding Cut Seals and Bearing Washers

What Are Cut Seals?

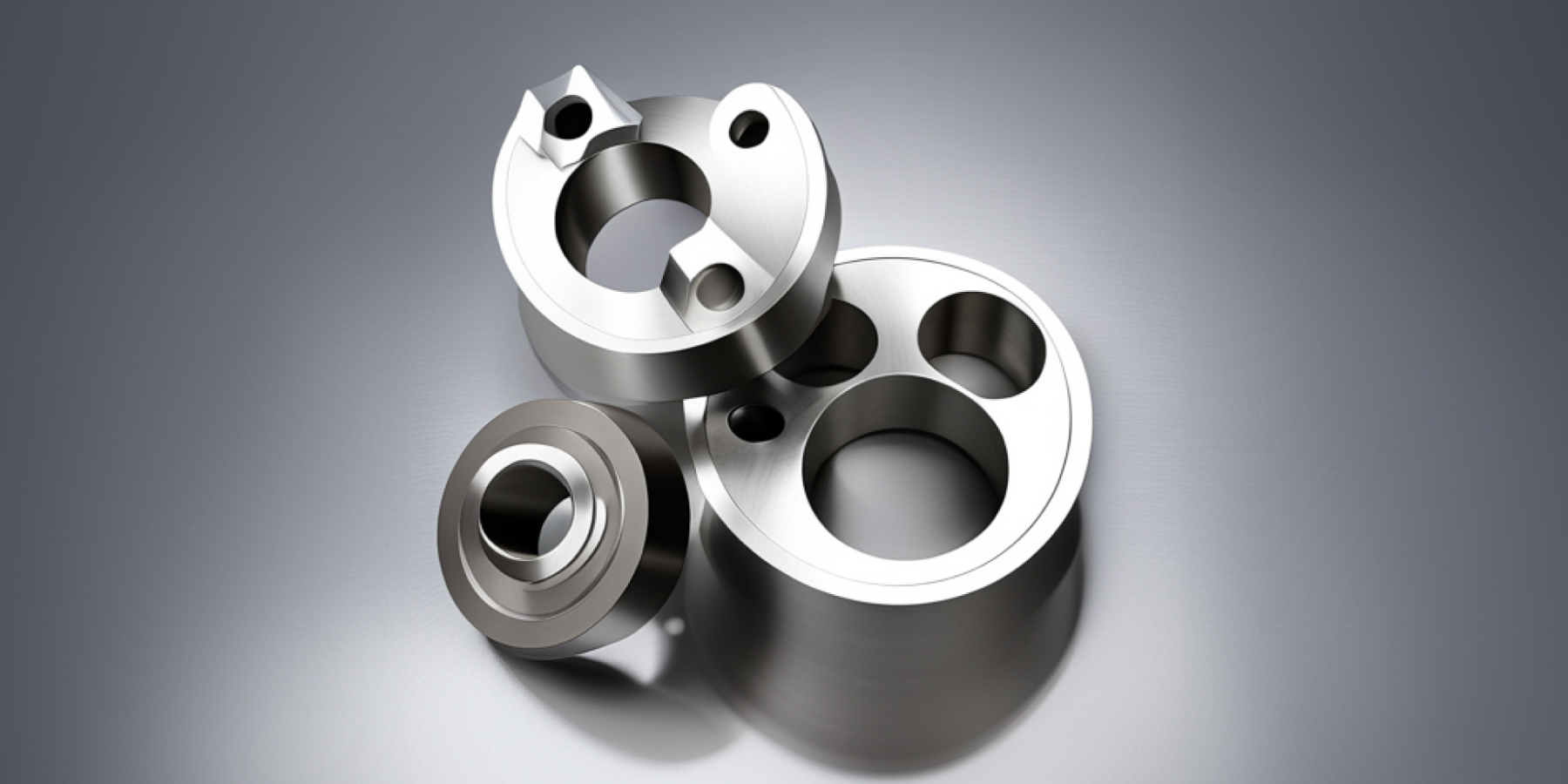

What Are Bearing Washers?

Bearing washers serve as a support surface for bearings, facilitating smooth movement and reducing friction between moving parts. These washers are critical in applications that require reliable load distribution and alignment, ensuring the longevity and performance of the machinery.

Key Features and Benefits

Advantages of Cut Seals

- Leak Prevention:

- Cut seals effectively prevent the leakage of liquids and gases, which is vital for maintaining system integrity and safety.

- Material Versatility:

- Available in various materials, cut seals can be tailored to withstand specific temperatures, pressures, and chemical exposures.

- Cost-Effective:

- By minimizing leaks and potential downtime, cut seals contribute to overall cost savings in operational efficiency.

- Leak Prevention:

Advantages of Bearing Washers

- Load Distribution:

- Bearing washers help distribute loads evenly across bearing surfaces, reducing the risk of wear and tear and extending the lifespan of machinery components.

- Friction Reduction:

- The smooth surface of bearing washers minimizes friction, promoting efficient movement and reducing energy consumption.

- Alignment Support:

- These washers ensure proper alignment of rotating parts, enhancing the overall performance of mechanical systems.

- Load Distribution:

Applications in Various Industries

Industries Using Cut Seals and Bearing Washers

- Automotive:

- In vehicles, cut seals and bearing washers are used in engines, transmissions, and other critical components to ensure optimal performance and reliability.

- Manufacturing:

- In manufacturing equipment, these components prevent leaks and reduce friction, ensuring smooth operations and minimal downtime.

- Aerospace:

- The aerospace industry relies on high-performance cut seals and bearing washers to maintain safety and efficiency in aircraft systems.

- Marine:

- In marine applications, cut seals are essential for preventing leaks in various systems, while bearing washers support the smooth operation of rotating components.

Conclusion

Incorporating high-quality cut seals and bearing washers into your machinery can significantly improve efficiency and reliability. Their ability to prevent leaks, reduce friction, and support load distribution makes them indispensable in various industrial applications.

Are you looking to maximize efficiency in your operations with top-notch cut seals and bearing washers? Contact us today to discover our range of products and find the ideal solutions tailored to your industry needs!

FAQs

Cut seals are typically made from rubber, silicone, or elastomers, which provide flexibility and resistance to temperature and chemical exposure.

Bearing washers help distribute loads evenly, reduce friction, and ensure proper alignment of moving parts, leading to enhanced efficiency and prolonged equipment life.

These components are widely used in automotive, manufacturing, aerospace, and marine industries, where they play a vital role in maintaining system integrity and performance.