Choosing the Right CNC Components Supplier for Precision Machined Parts

In the highly competitive world of precision engineering, finding the right CNC components supplier is crucial for ensuring high-quality CNC machined components. Whether your business requires precision machined parts for automotive, aerospace, or medical applications, selecting the right supplier can make a significant difference in product performance and durability. In this blog, we’ll explore the key factors to consider when choosing a CNC components supplier, how to ensure you get the highest quality precision machined components, and why selecting the right partner can drive long-term success.

Why the Right CNC Components Supplier Matters

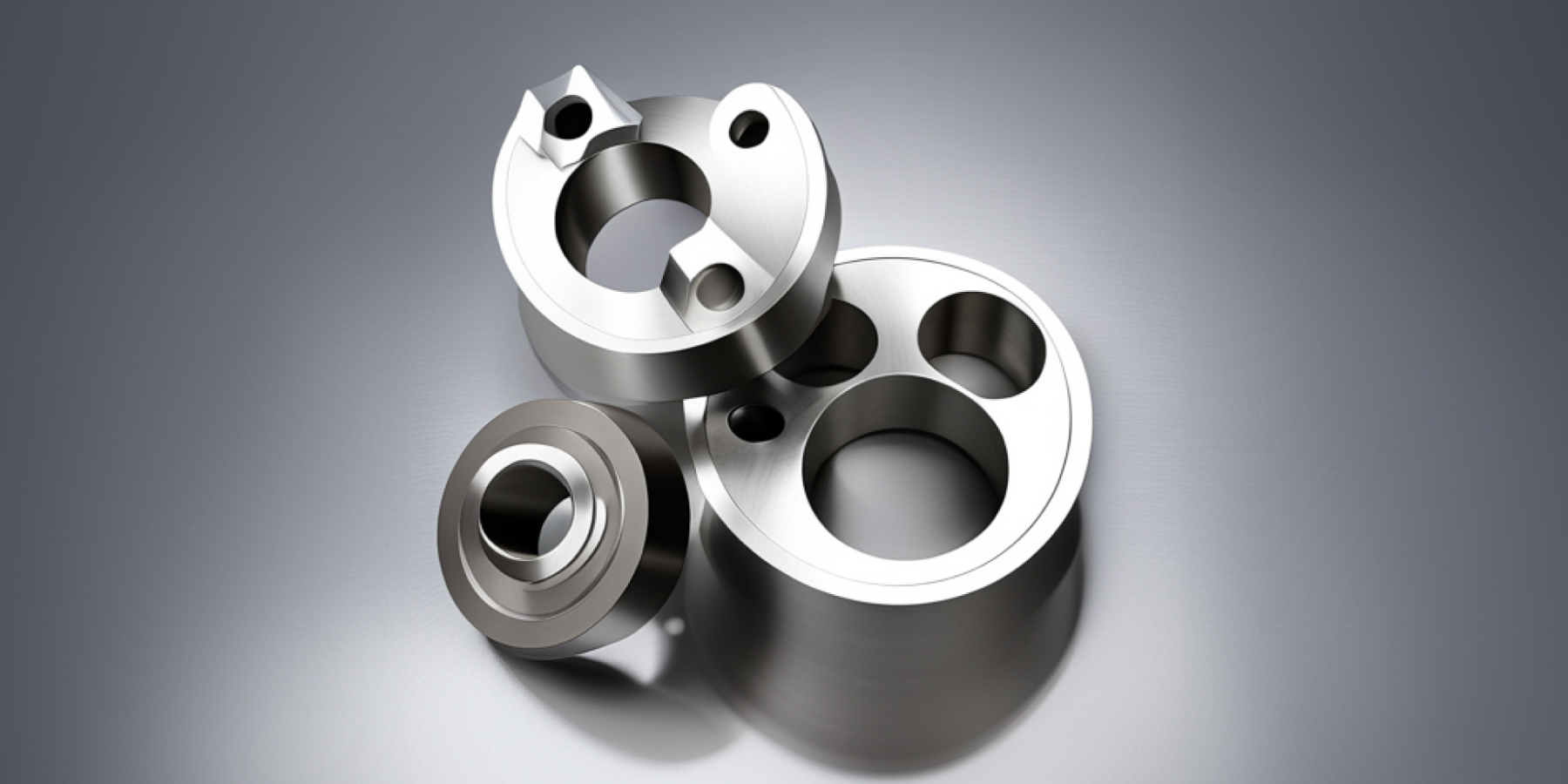

The manufacturing industry relies on precision, especially when it comes to CNC machined parts. Precision components are used in complex machinery where the smallest error can result in malfunctions or decreased efficiency. Working with a reliable CNC components supplier ensures that your parts are crafted to meet exact specifications, minimizing errors and maximizing performance.

Key Factors When Choosing a CNC Components Supplier

1. Experience and Expertise in Precision Machining

Look for suppliers who have years of experience in precision machined components. An experienced supplier will have better insight into your needs and can provide solutions that ensure optimal quality and performance. They are also more likely to have invested in the latest CNC machining technology, which is critical for delivering high-quality CNC machined parts.

2. Material Variety and Customization

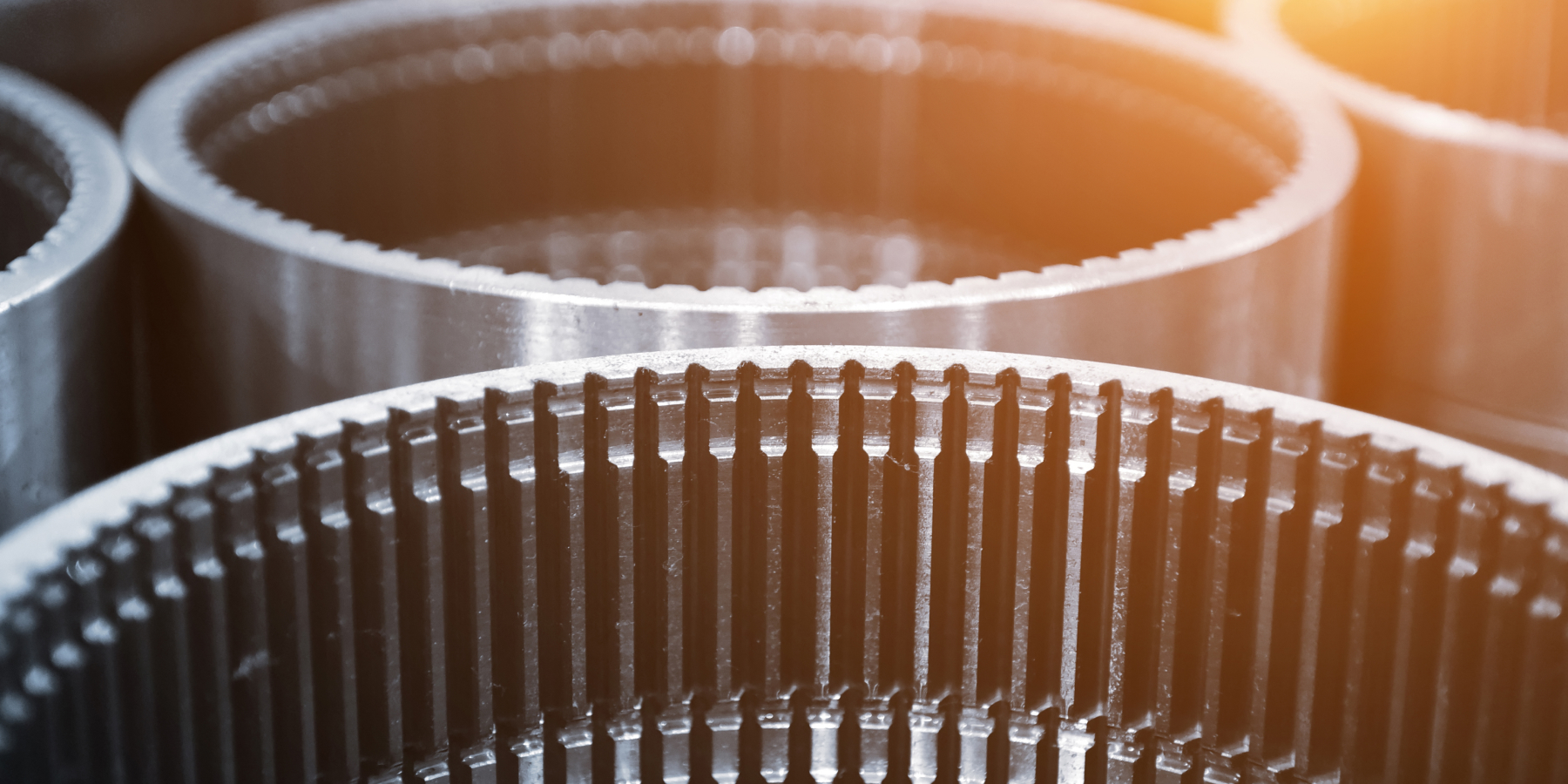

The supplier should offer a wide range of materials, from aluminum and steel to advanced alloys. More importantly, they should be able to provide precision machined parts that meet your exact specifications, whether it involve complex geometries or tight tolerances.

3. Certifications and Quality Assurance

Ensure that the supplier holds relevant certifications, such as ISO 9001, to guarantee that they adhere to high industry standards. Consistent quality control processes are crucial when producing precision machined components, especially in industries that cannot afford errors, such as aerospace or medical device manufacturing.

4. State-of-the-Art Technology and Innovation

A top CNC components supplier will use state-of-the-art equipment, such as 5-axis CNC machines, to deliver precise and complex parts. The use of cutting-edge technology ensures that your CNC machined components are produced efficiently, minimizing turnaround time without compromising quality.

5. Timely Delivery and Reliable Communication

Delays in receiving precision machined parts can lead to operational downtime, affecting your business profitability. Choose a supplier who prioritizes timely deliveries and has a track record of meeting deadlines. Moreover, communication is key—your supplier should be transparent about lead times and keep you informed throughout the manufacturing process.

Advantages of Precision Machined Components

- High Accuracy and Consistency: CNC machines operate with minimal human intervention, ensuring that each part is identical and meets tight tolerances.

- Efficiency and Cost-Effectiveness: CNC machining is ideal for large-scale production where accuracy and repeatability are essential.

- Material Flexibility: Whether your application requires metals, plastics, or composites, CNC machining offers a versatile solution.

Industries That Rely on Precision Machined Parts

- Aerospace: CNC machining ensures that aircraft components meet strict safety and performance standards.

- Automotive: From engine parts to intricate dashboard components, precision machining plays a critical role in automotive manufacturing.

- Medical: In the medical device industry, precision is paramount, and CNC machining is often used to create critical components such as surgical instruments and prosthetics.

Conclusion

Choosing the right CNC components supplier is crucial for ensuring the quality, efficiency, and performance of your precision machined parts. By considering factors such as experience, customization options, and timely delivery, you can make an informed decision that supports your business’s long-term success.

FAQs

Look for experience, certifications, material variety, and cutting-edge technology. The supplier should be reliable and have a good track record of timely deliveries.

Precision ensures that parts meet exact specifications, which is essential for industries like aerospace, automotive, and medical devices where safety and performance are critical.

Precision machined components are used in aerospace, automotive, medical, and industrial manufacturing, among other industries.

With the right equipment and expertise, CNC suppliers can reduce production time while maintaining high-quality standards, making the process more cost-effective.