Double-Headed Motor and Rotor Shafts Advantages to Boost Efficiency

The vast majority of machinery runs off two vital elements: double-headed motors and rotor shafts. The paper reviews the benefits, areas of application, and new developments surrounding these critical components, which help you learn how to bring improvement into your industrial processes.

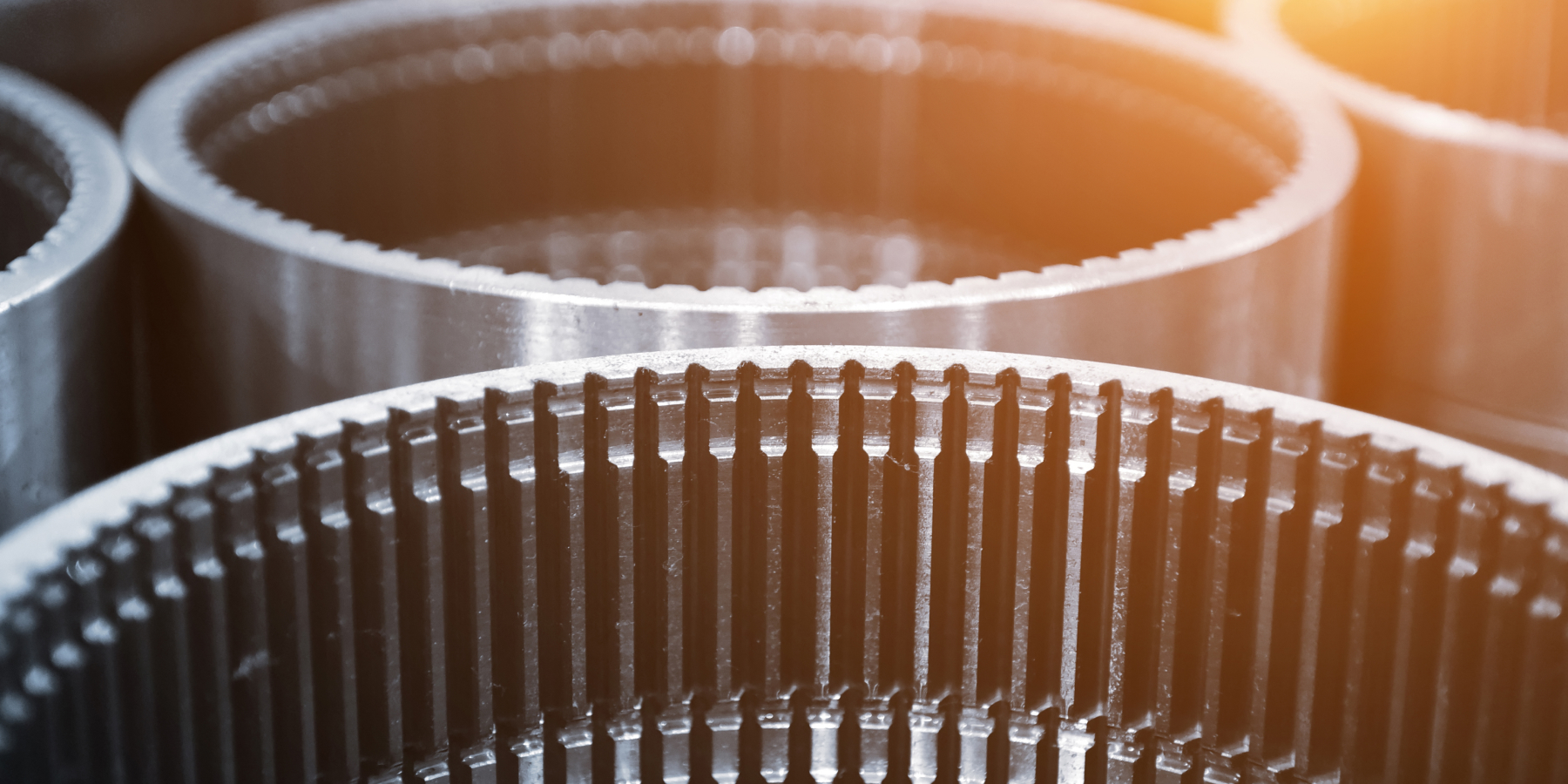

What are Double-Headed Rotor Shafts?

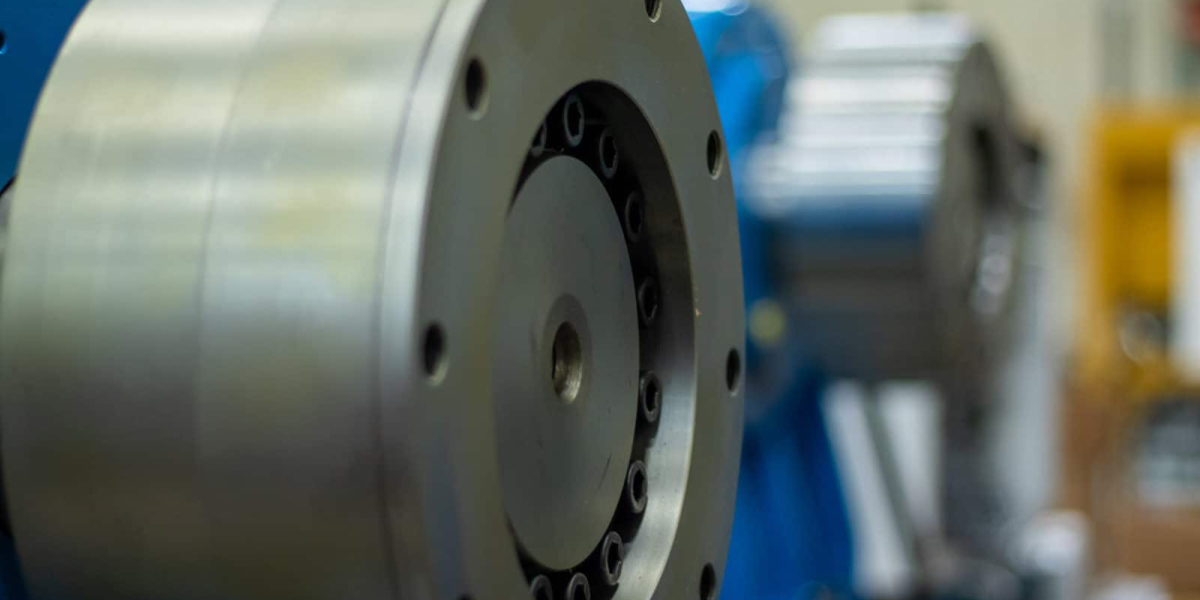

Double-headed rotor shafts are applied in many industries and mechanical devices. The dual heads of the design ensure stable and balanced rotation, placing them in generators, motors, and other devices with high precision and reliability.

Advantages:

This dual-headed design gives rise to equilibrated forces of rotation that bring down vibrations and increase overall stability.

- High system Efficiency: Stable rotation of double-headed rotor shafts enhances the system’s performance and efficiency.

- Durability: Heavy loads and some difficult operational conditions may be more easily withstood using these shafts since they are fabricated from quality material to ensure reliability over a lengthy period.

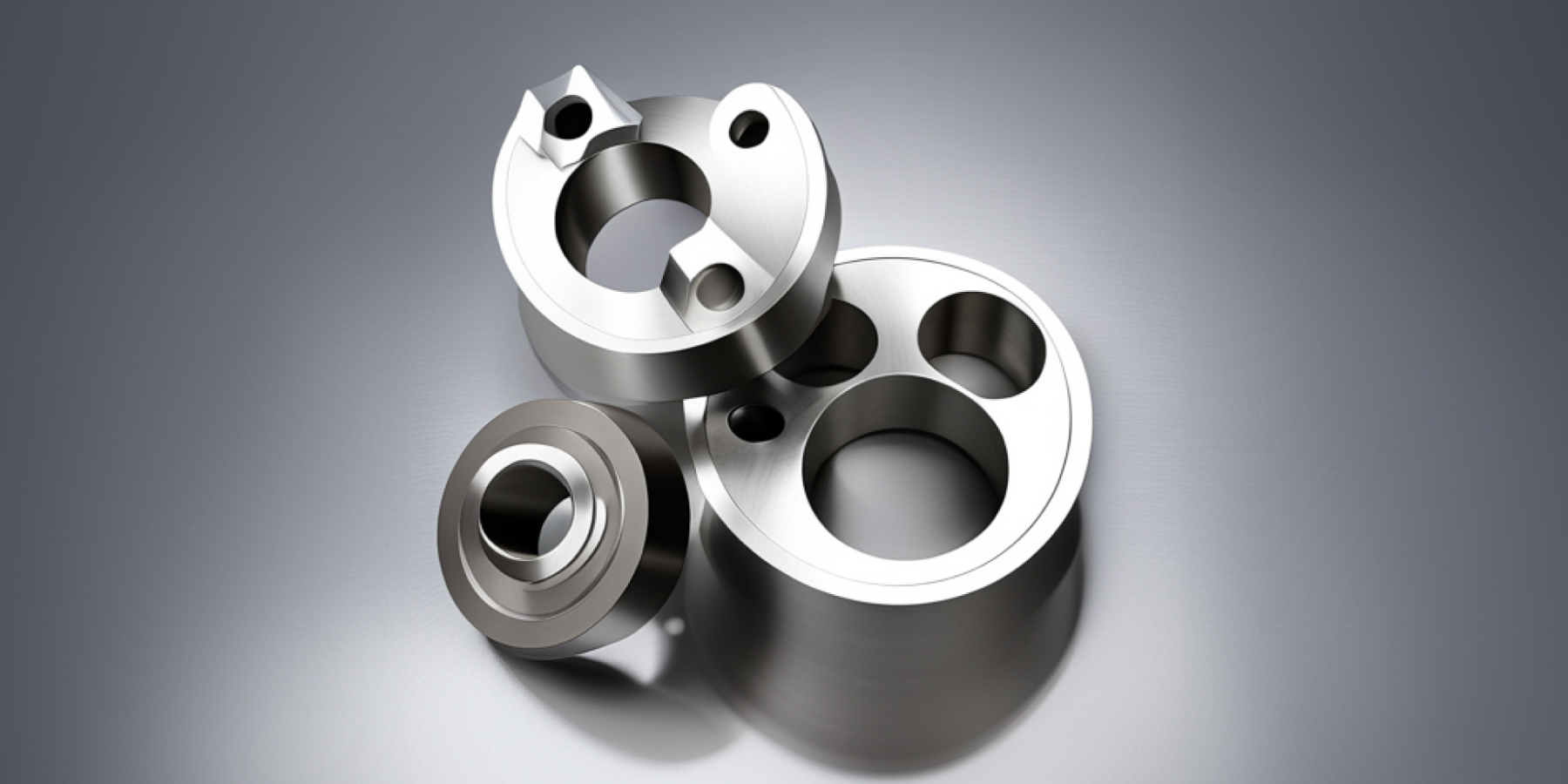

What is a Motor Shaft?

Motor shafts are integral portions of a motor from which power is transmitted to the intended application. Such shafts have to be highly precisely engineered so that power is transferred to the application with minimal loss of energy.

Key Benefits:

- Precision Engineering: Motor shafts are highly precise in nature and assure perfect alignment and optimum power transfer.

- Versatility: These are widely used; their application varies from small appliances at home to big industrial machinery.

- Energy Efficiency: A good design of the motor shafts ensures minimum loss of energy, hence overall system efficiency.

Double-Headed Rotor Shafts vs. Motor Shafts: Applications

- Double-Headed Rotor Shafts: Used in high-stability applications with balanced rotational forces, such as in wind turbines, industrial mixers, and some types of pumps.

- Motor Shafts: Used in many electric motors of domestic appliances, automotive engines, HVAC, and industrial equipment.

Material Considerations:

– Double-Headed Rotor Shafts: Many of these are fabricated from robust material bases, such as stainless steel or high-strength alloys, to overcome stressful conditions.

– Motor Shafts: These are made of materials that provide optimum levels of strength and machinability, ranging from carbon steel to alloy steels.

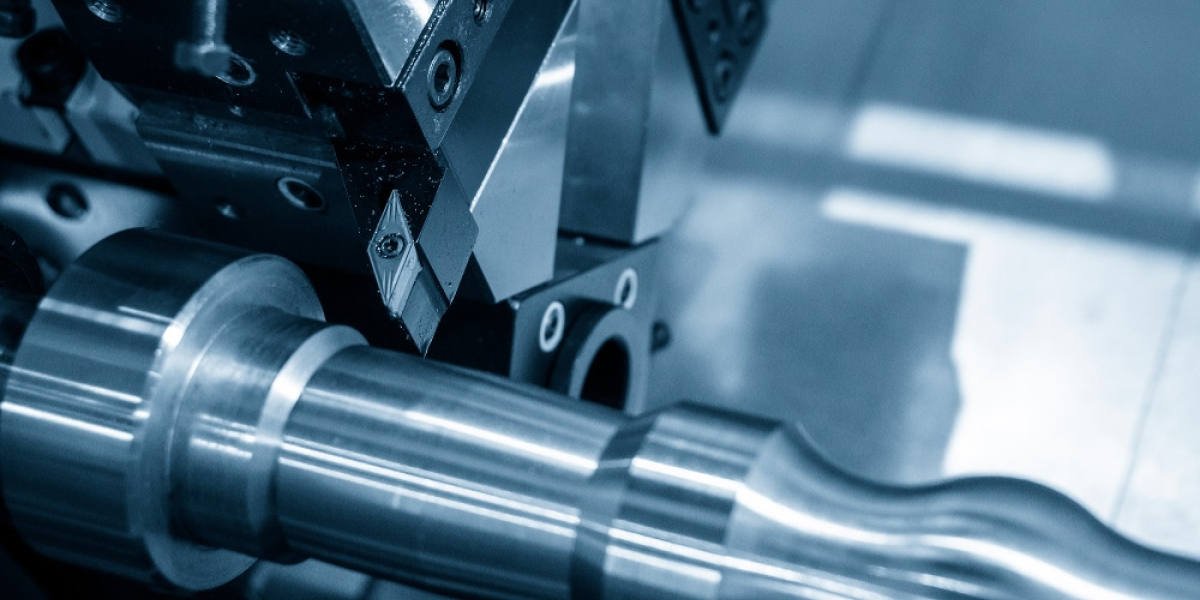

Shaft Design Innovation

Material Advancements:

Material science innovations have come up with new alloys and composites that improve the performance and durability of both double-headed rotor shafts and motor shafts.

Manufacturing Accuracy:

The state-of-the-art manufacturing processes involve CNC machining and forging methods of high-end quality and efficiency in making such shafts.

Smart Technologies:

It is also due to Industry 4.0 that smart sensors and monitoring systems are often integrated into shaft designs for tracking performance in real-time and predictive maintenance, further optimizing efficiency and reliability

Conclusion

The double-headed rotor shafts and the motor shafts—the two integral components in any modern machinery—give extra balance, stability, and efficiency. Now, knowing their unique advantages and applications, you’ll be better placed to make an informed decision when you look to optimize your industrial processes.