Optimizing Industrial Systems: A Comprehensive Guide to Seals, Bearings, Valves, Shafts, and CNC Machined Parts

In the modern industrial landscape, optimizing system components is crucial for enhancing operational efficiency, reducing downtime, and improving product quality. Key components such as seals, bearings, valves, shafts, and CNC machined parts play a vital role in ensuring that machinery and systems run smoothly. This guide delves into each component’s functions, types, applications, and best practices for selection and maintenance.

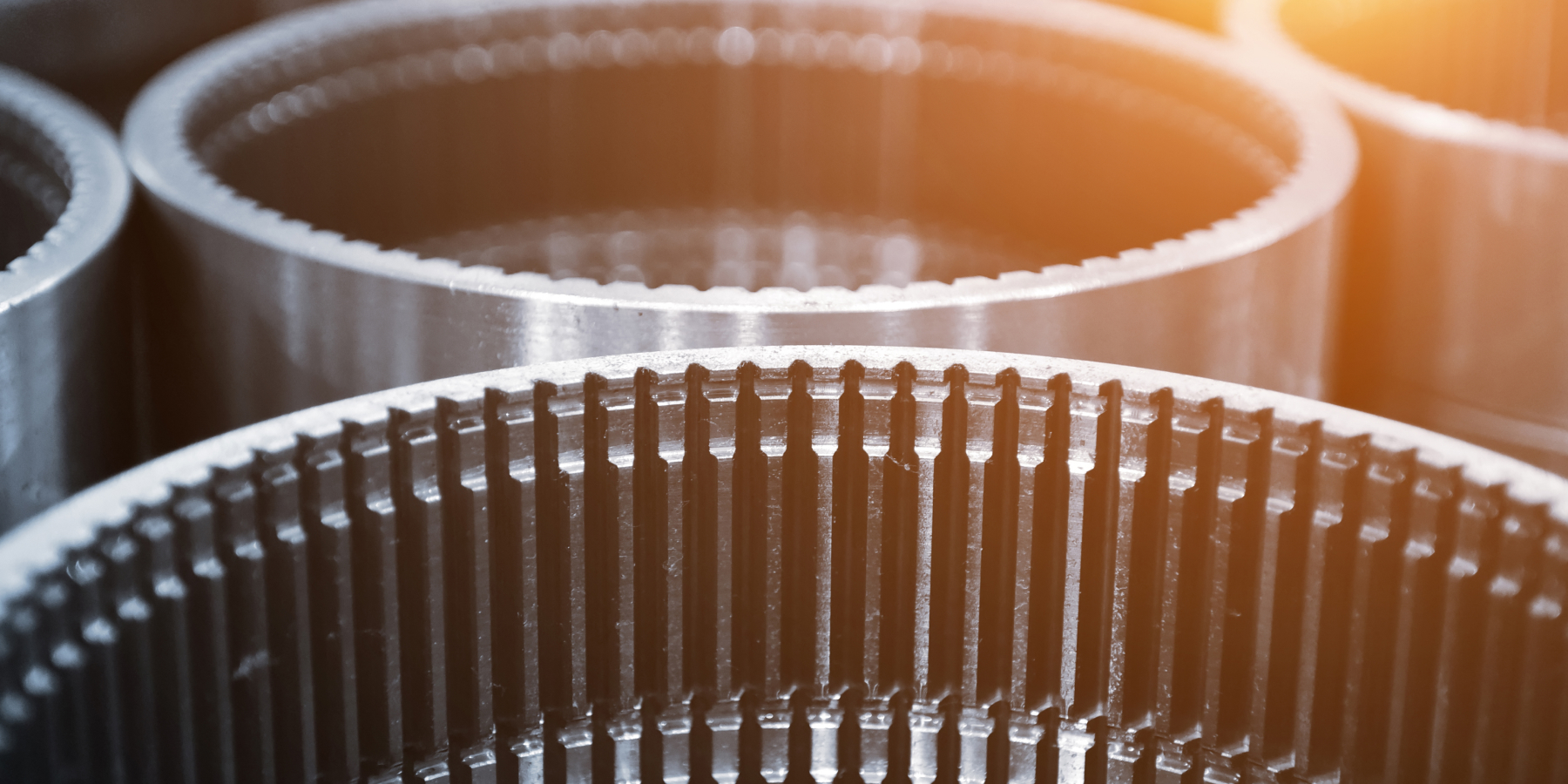

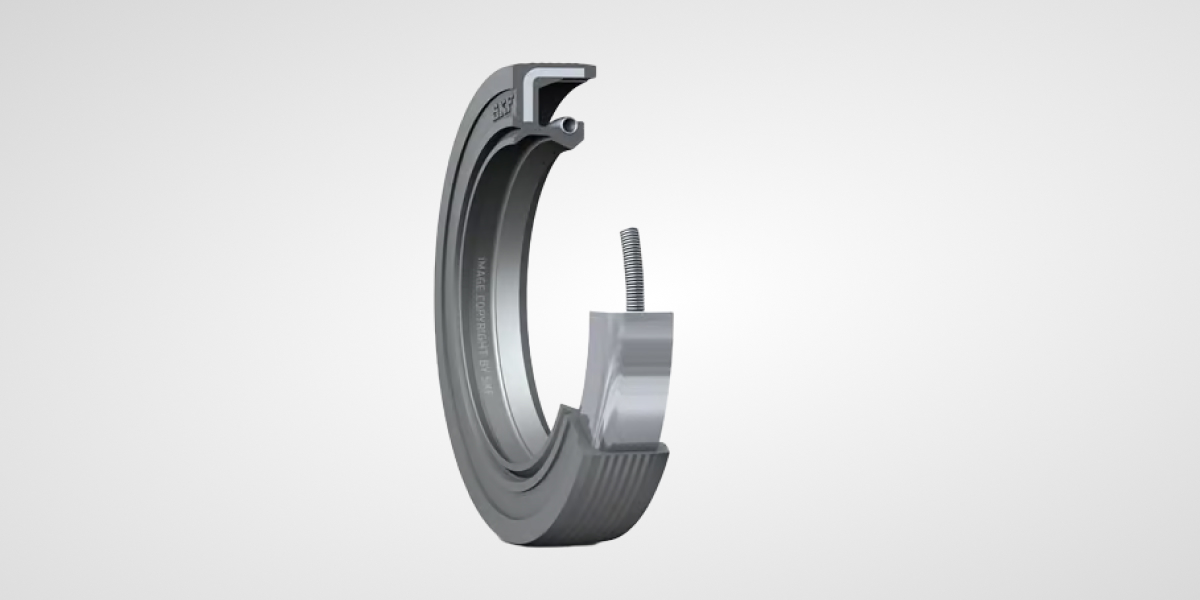

Understanding Seals and Bearing Washers

The Role of Cut Seals

Cut seals are integral to preventing leaks and protecting systems from contaminants. They are custom-designed to fit specific applications, making them versatile for various industries, including:

- Oil and Gas: Ensuring leak-free operation in pipelines and storage tanks.

- Manufacturing: Protecting machinery from dust and moisture.

Pharmaceuticals: Maintaining sterile conditions in processing equipment.

Key Characteristics:

- Material Options: Available in elastomers, PTFE, and other materials for compatibility with various fluids and temperatures.

- Customization: Tailored designs to fit specific dimensions and operational requirements.

The Importance of Bearing Washers

Bearing washers provide a smooth interface for bearings to operate efficiently. Their proper selection is crucial for minimizing friction and wear, which can lead to equipment failure. Common applications include:

- Rotating Equipment: Used in motors, pumps, and gearboxes.

- Heavy Machinery: Essential for ensuring longevity in construction and mining equipment.

Best Practices:

- Material Selection: Choose materials based on load requirements and environmental conditions.

- Regular Inspections: Monitor for wear and tear to prevent failures.

Exploring Stainless Steel Extended Spindle Ball Valves

Extended spindle ball valves offer several advantages in various applications:

Valve Spindle vs. Stem: Key Differences

- Valve Spindle: This component is connected to the valve handle and controls the ball’s position, regulating flow.

- Valve Stem: Part of the internal mechanism that opens and closes the valve. Understanding this distinction is vital for maintenance and troubleshooting.

Applications:

- Chemical Processing: Ensures safe and efficient handling of fluids.

- Water Treatment: Controls water flow in purification systems.

The Significance of Double-Headed Rotor Shafts

Double-headed rotor shafts are essential in motor systems, providing enhanced functionality for various applications:

Motor Shaft and Rotor Shaft

- Motor Shaft: Transmits mechanical power from the motor to the driven equipment, crucial for overall system efficiency.

- Rotor Shaft: Connects to the rotor, facilitating rotation and ensuring the motor operates correctly.

Applications:

- HVAC Systems: Used in fans and compressors.

- Industrial Equipment: Integral to the operation of conveyors and pumps.

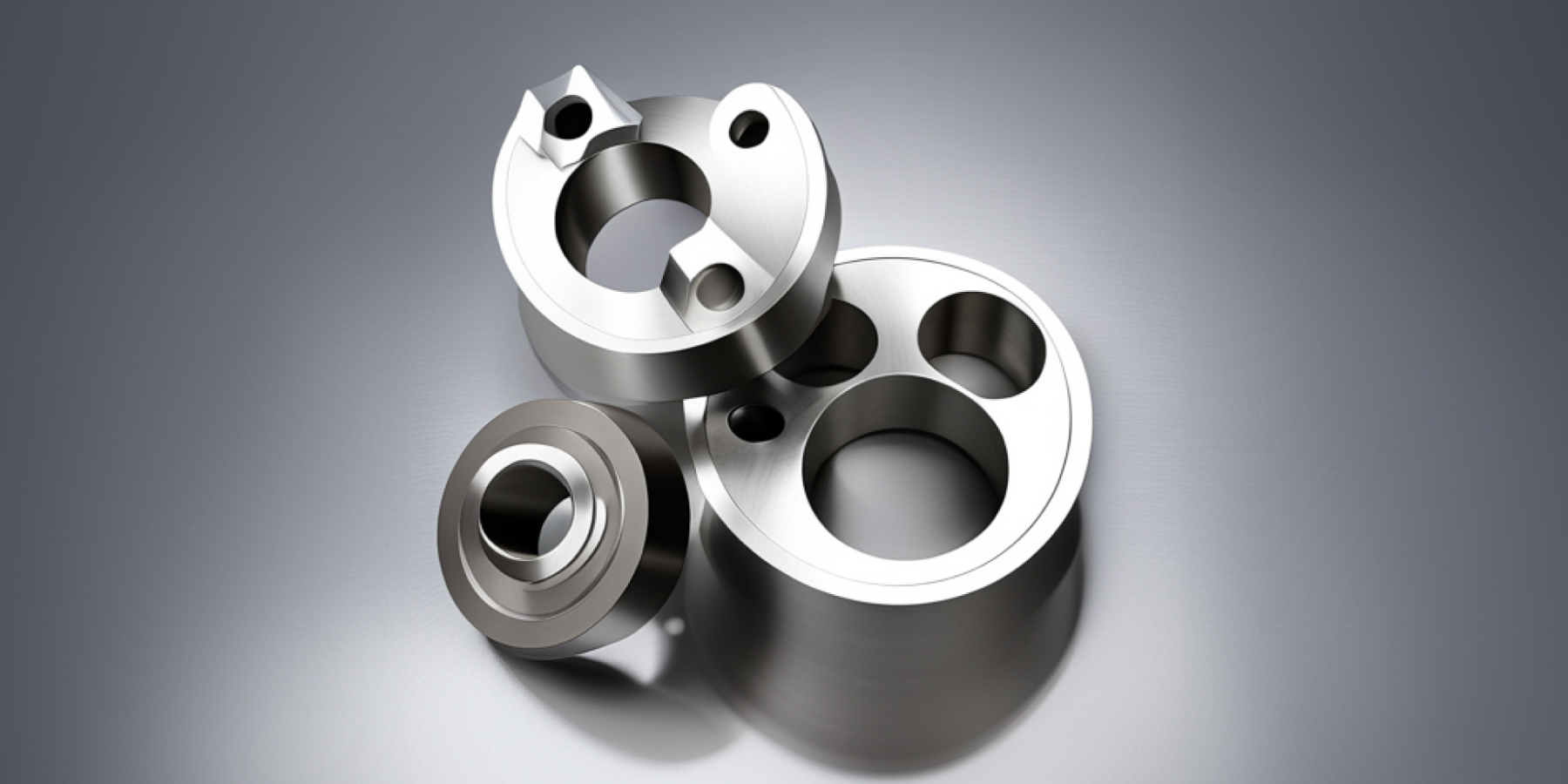

The Role of CNC Machined Parts in Industrial Optimization

CNC machined components are vital for precision and efficiency in manufacturing:

Importance of Precision Machined Components

Precision-machined parts are crafted to exact specifications, making them essential for applications that require high reliability. Common industries utilizing these components include:

- Aerospace: Critical for safety and performance.

- Automotive: Ensures precise fit and function in vehicle assemblies.

Benefits of CNC Machining:

- High Tolerance: Capable of producing components with tight tolerances, which is critical for performance.

- Material Versatility: Supports a wide range of materials, including metals, plastics, and composites.

Choosing a CNC Components Supplier

When selecting a CNC components supplier, consider the following factors:

- Reputation: Look for a supplier with positive reviews and a history of quality.

- Capabilities: Ensure they have the machinery and expertise to meet your specifications.

- Customer Support: Evaluate their responsiveness and willingness to collaborate.

Conclusion

Optimizing industrial systems requires a comprehensive understanding of seals, bearings, valves, shafts, and CNC machined parts. Each component plays a crucial role in ensuring operational efficiency and reliability. Businesses can significantly enhance their performance by investing in high-quality materials and maintaining them properly.

Are you ready to optimize your industrial systems with high-quality components? Contact us today to learn more about our comprehensive range of seals, bearings, valves, and CNC-machined parts tailored to meet your specific needs!

FAQs

Cut seals are designed to prevent leaks in industrial applications. They fit precisely into designated spaces, providing a secure seal that protects against contaminants and moisture, thus enhancing the longevity of machinery.

The valve spindle connects the handle to the valve mechanism, allowing for control over fluid flow, while the valve stem is part of the internal assembly that directly opens and closes the valve. Understanding this difference is essential for proper maintenance and operation.

CNC machined parts provide high precision and consistency, which are crucial for applications requiring strict tolerances. They enhance product reliability and performance, making them indispensable in various industries.