Strength of Rolled Ring Forgings: Key Applications and Benefits

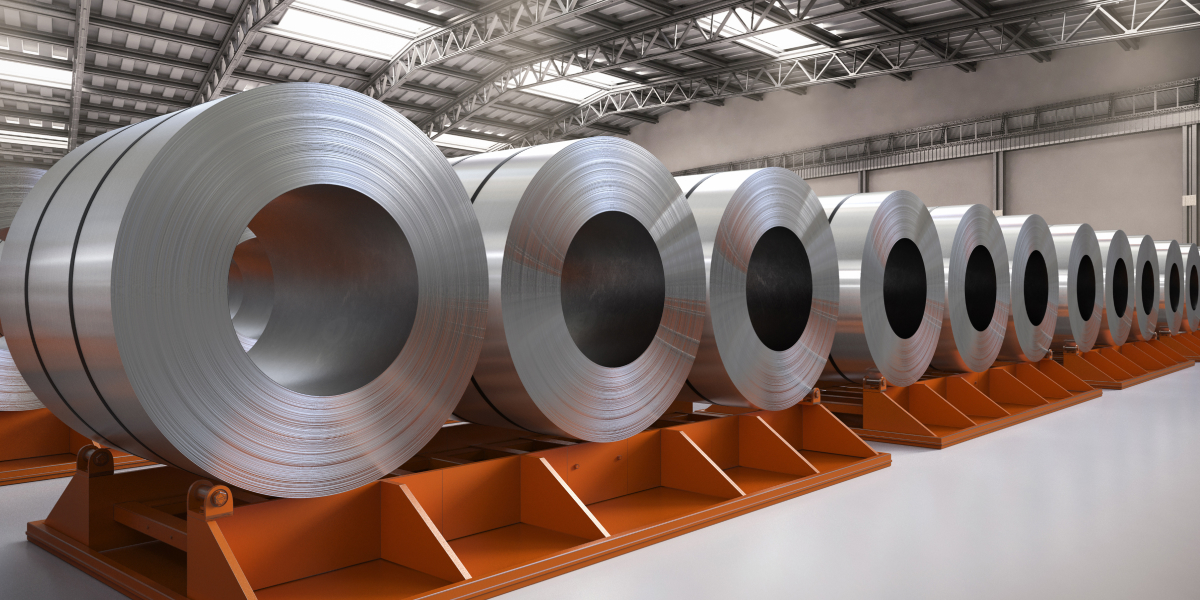

Rolled ring forgings are integral to numerous industries, and are prized for their exceptional strength, durability, and reliability in critical applications. Unlike traditional casting or machining methods, the unique manufacturing process of rolled ring forging enhances the structural integrity and performance of these components. Let’s explore why rolled ring forgings are indispensable in modern industrial applications.

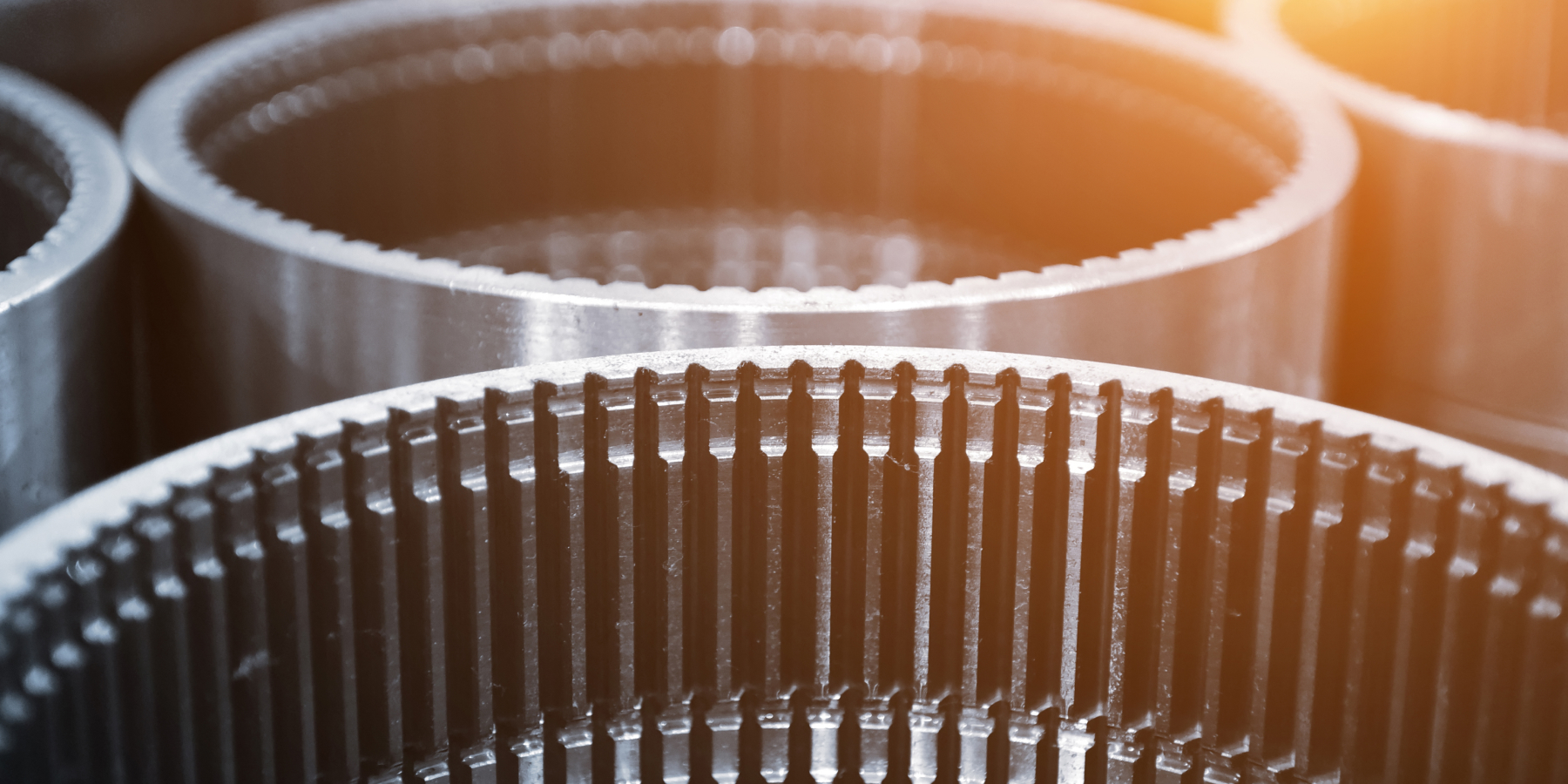

Understanding Rolled Ring Forgings

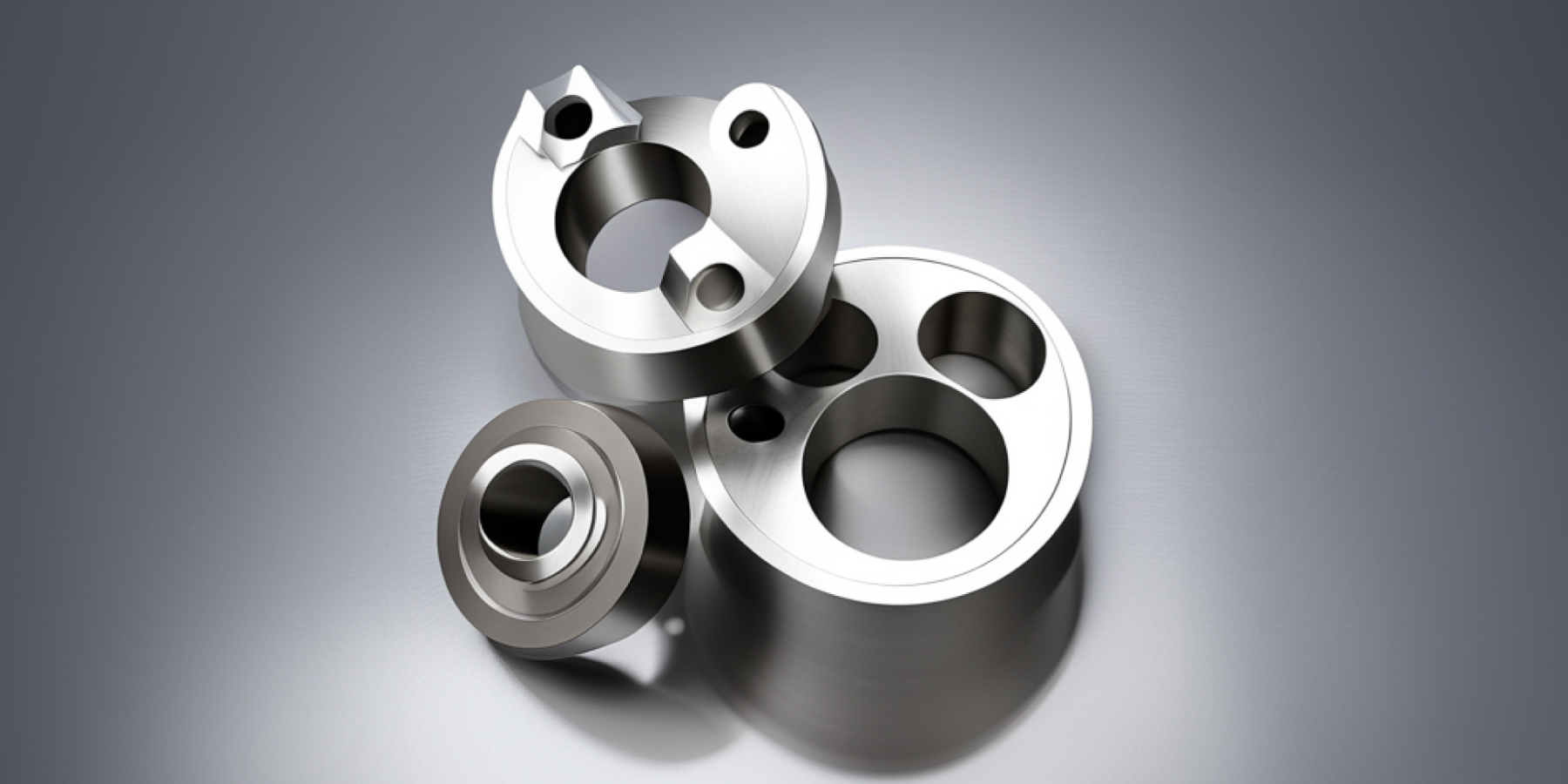

- Rolled ring forgings are produced by shaping a heated metal billet between two rollers. This process eliminates the need for welding or machining from a solid block of metal, resulting in a seamless, high-strength ring. This seamless structure enhances the mechanical properties of the material, including fatigue resistance and impact toughness, making rolled rings ideal for demanding environments.

Applications Across Industries

- Aerospace and Defense: In aerospace applications, such as jet engines and landing gear, rolled ring forgings withstand extreme temperatures, pressures, and dynamic loads while maintaining structural integrity and reliability.

- Oil and Gas: Used in drilling equipment, valves, and pipelines, rolled rings offer exceptional durability and corrosion resistance in harsh offshore and onshore environments.

- Power Generation: Essential for turbines, generators, and other power plant components, rolled ring forgings ensure reliable performance under high temperatures and mechanical stress.

4. Automotive and Transportation: From heavy-duty truck components to high-performance automotive parts, rolled rings provide strength and reliability in drivetrain systems and steering components.

Advantages of Rolled Ring Forgings

- Enhanced Mechanical Properties: The forging process aligns the grain structure of the metal, resulting in superior strength, fatigue resistance, and impact toughness compared to castings or weldments.

- Cost-Effectiveness: While initial setup costs may be higher than other methods, the efficiency of production and minimal material waste make rolled ring forgings a cost-effective solution over the long term.

- Customization Options: Manufacturers can tailor rolled ring forgings to precise specifications, including size, material type, and finish, ensuring optimal performance in specific applications.

Quality Assurance and Compliance

Manufacturers adhere to rigorous quality standards and certifications, such as ISO 9001 and AS9100, ensuring that rolled ring forgings meet or exceed industry requirements for reliability and safety. Quality control measures throughout the production process guarantee consistent performance and durability.

Choosing the Right Supplier

When selecting a supplier for rolled ring forgings, consider their experience, capabilities, and commitment to quality. Look for a partner with advanced manufacturing facilities, a track record of delivering on time and within budget, and a proactive approach to customer service.

Conclusion

Rolled ring forgings continue to be the preferred choice for industries demanding high-performance, durable components. Their unmatched strength, reliability, and versatility make them indispensable in critical applications across aerospace, oil and gas, power generation, automotive, and more. As you embark on your next project requiring precision-engineered components, partner with a trusted supplier who understands your unique requirements and delivers excellence in rolled ring forgings.