Exploring the Versatility of CNC Machined Components

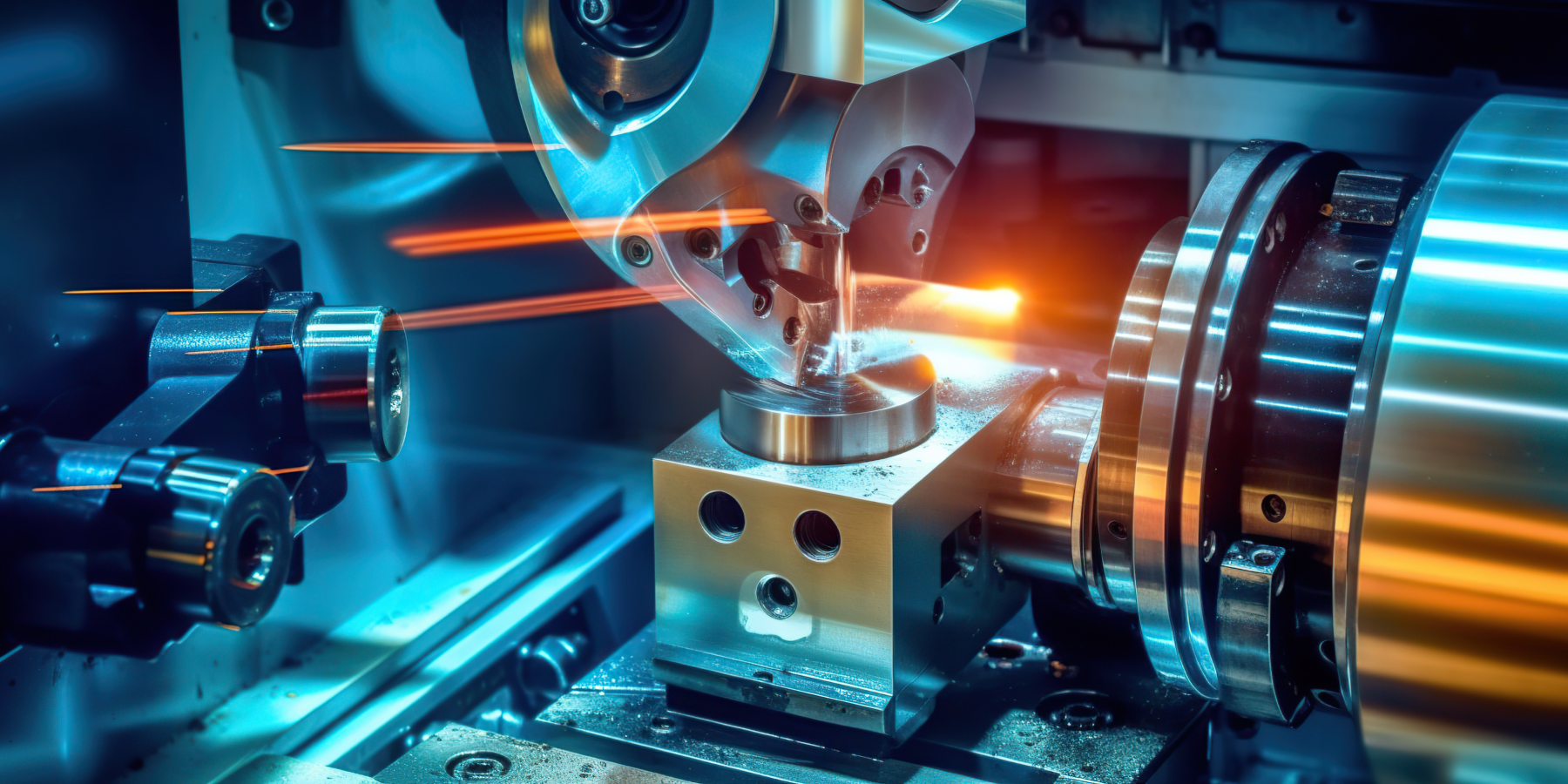

CNC-machined components are essential in today’s manufacturing world. CNC, which stands for Computer Numerical Control, allows for the precise and automated production of complex parts. Let’s dive into what makes CNC components so special and how they are used in various industries.

Brief Overview of CNC machined components

CNC components are parts made using machines controlled by computers. These machines can cut, drill, and shape materials with high precision. This technology is used to make many different parts, from tiny screws to large engine blocks. Let’s look at the key features that make CNC components so valuable.

Key Features of CNC Machined Components

CNC-machined components have several key features that make them highly desirable in many industries.

1. Accuracy

CNC-machined components are known for their high accuracy. These machines can make parts with very tight tolerances, ensuring that each piece fits perfectly. This level of precision is essential for components that must work together seamlessly.

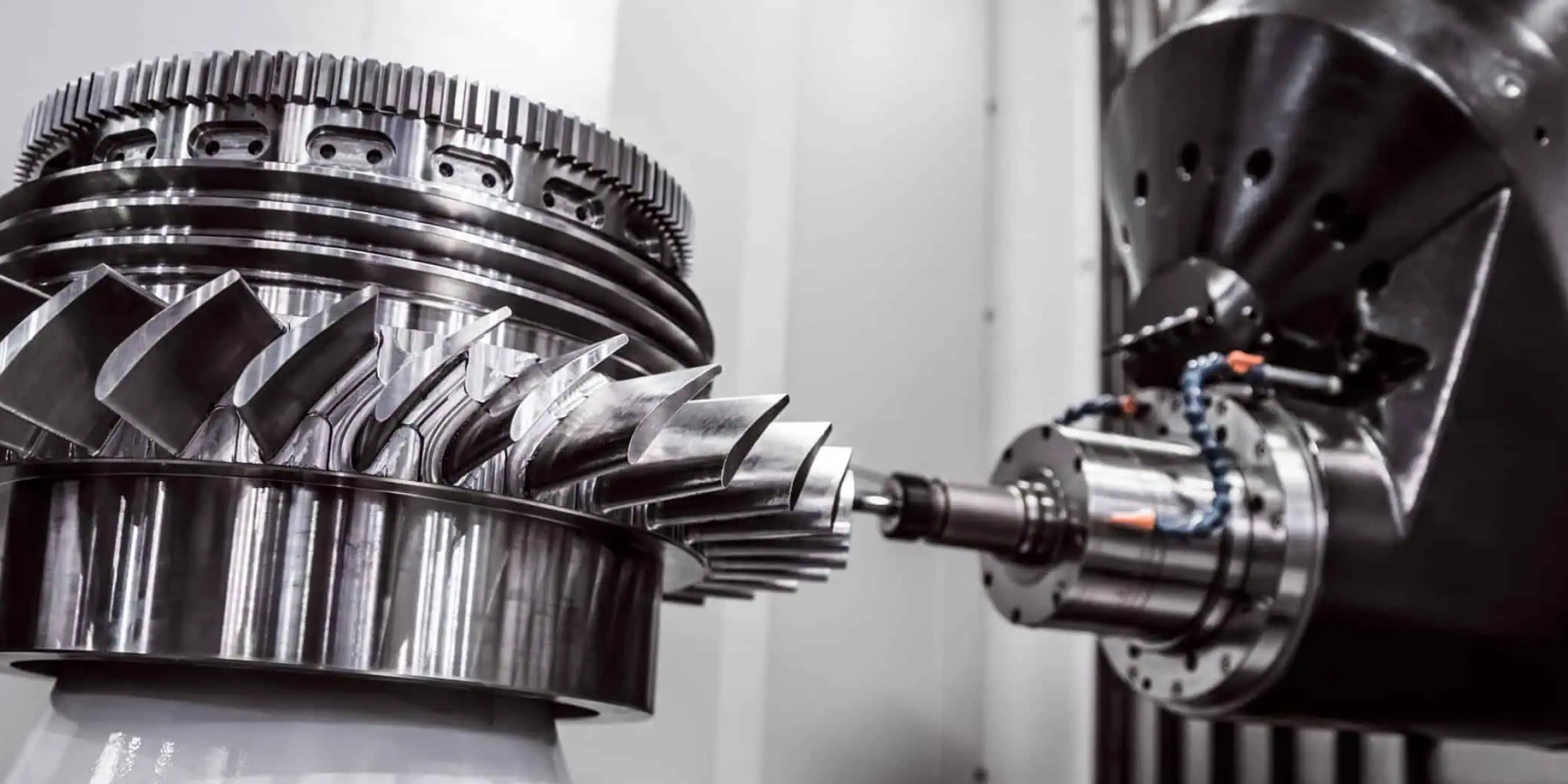

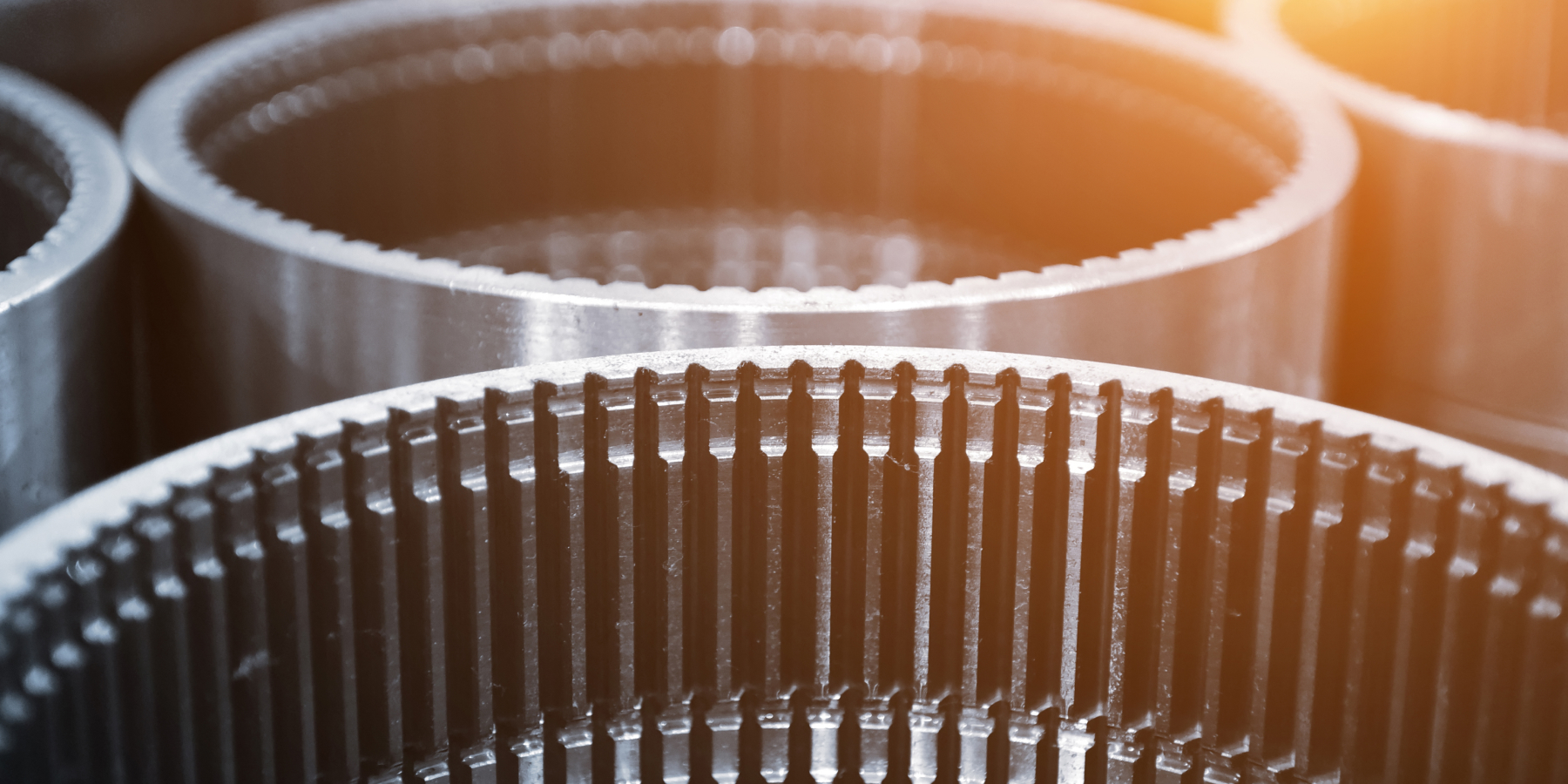

2. Complex Geometries

CNC machining can create parts with intricate shapes. This means components can have twists, turns, and curves that fit perfectly. With CNC technology, even the most complicated designs can be brought to life accurately.

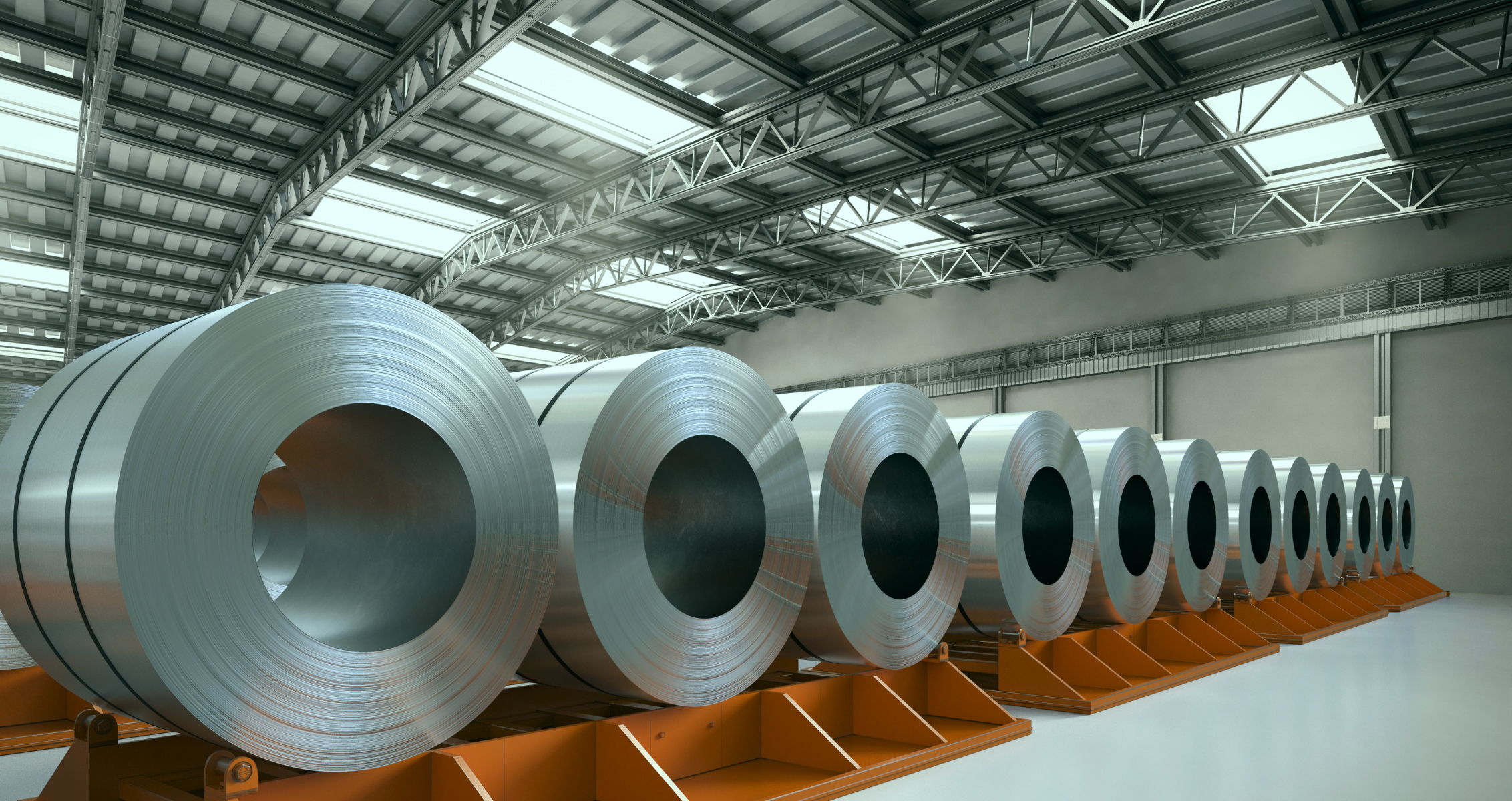

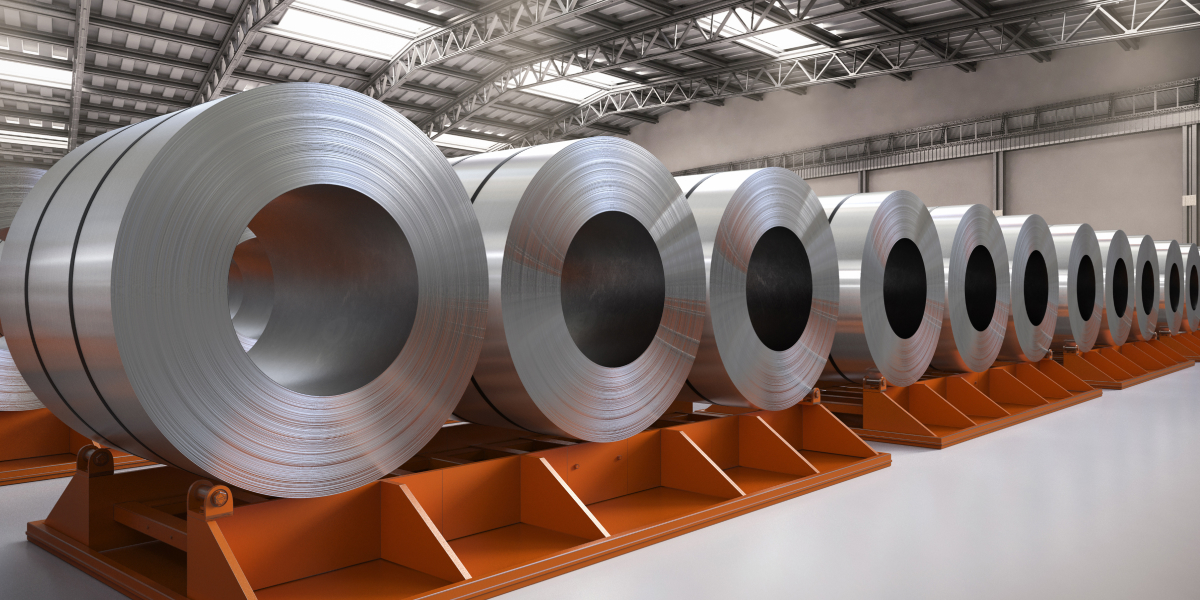

3. Wide Range of Materials

CNC machining can work with many different materials like metals, plastics, and wood. This versatility makes it useful for various industries, from automotive to electronics. With CNC machining, you can create parts that meet specific needs without compromising on quality.

4. Superior Surface Finish

CNC machining ensures parts have a smooth surface finish. This means they feel sleek and fit together snugly. With a superior surface finish, components work efficiently and look polished. In conclusion, CNC-machined components offer precision and quality.

5. Customization

Customization is key in CNC machining. It allows for making parts tailored to specific needs. Whether it’s adjusting dimensions or adding unique features, CNC machines can handle it. This flexibility ensures that every component meets exact requirements.

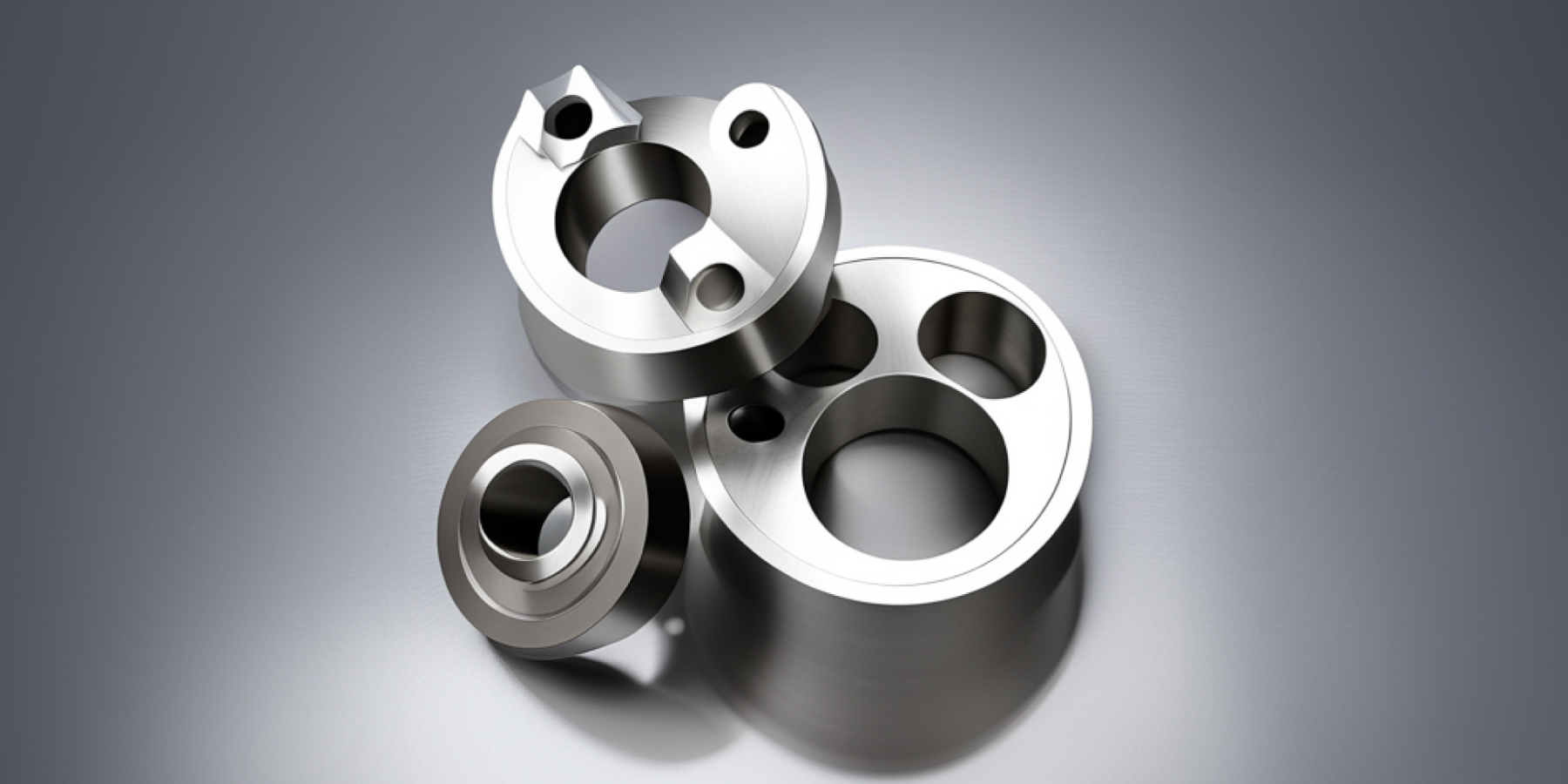

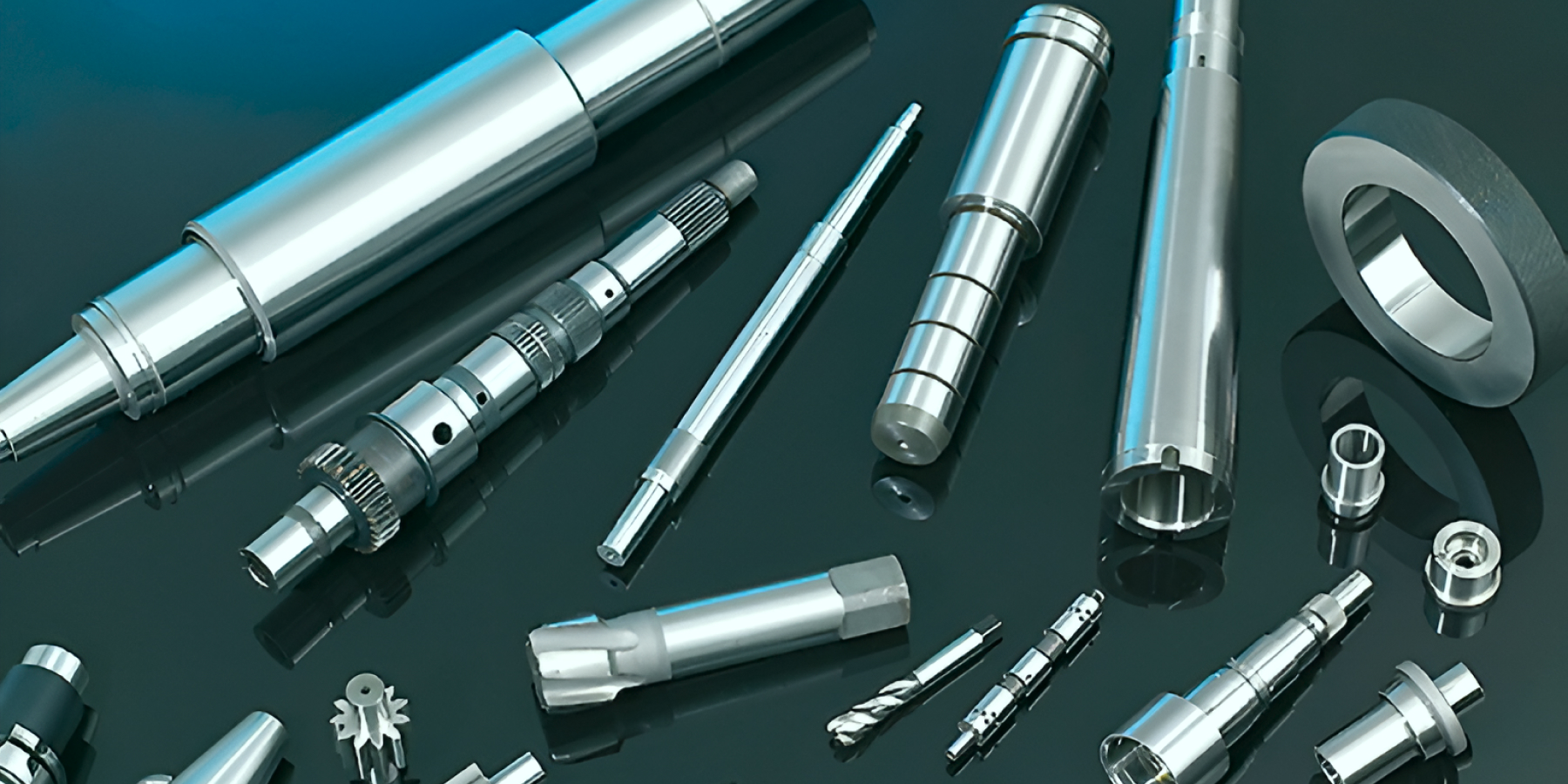

Types of CNC Machined Components

There are many types of CNC components, each serving a different purpose. Here are some common types:

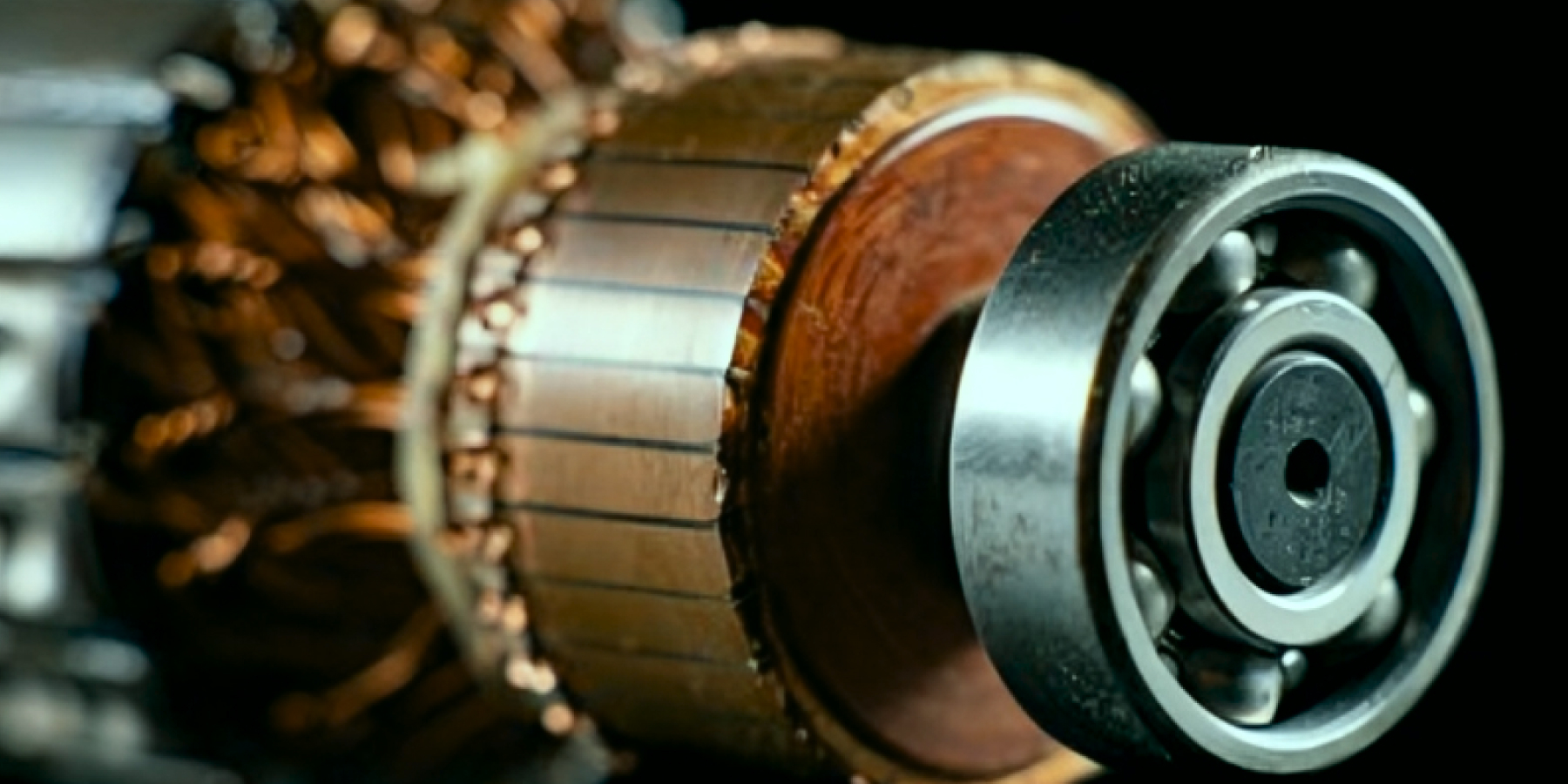

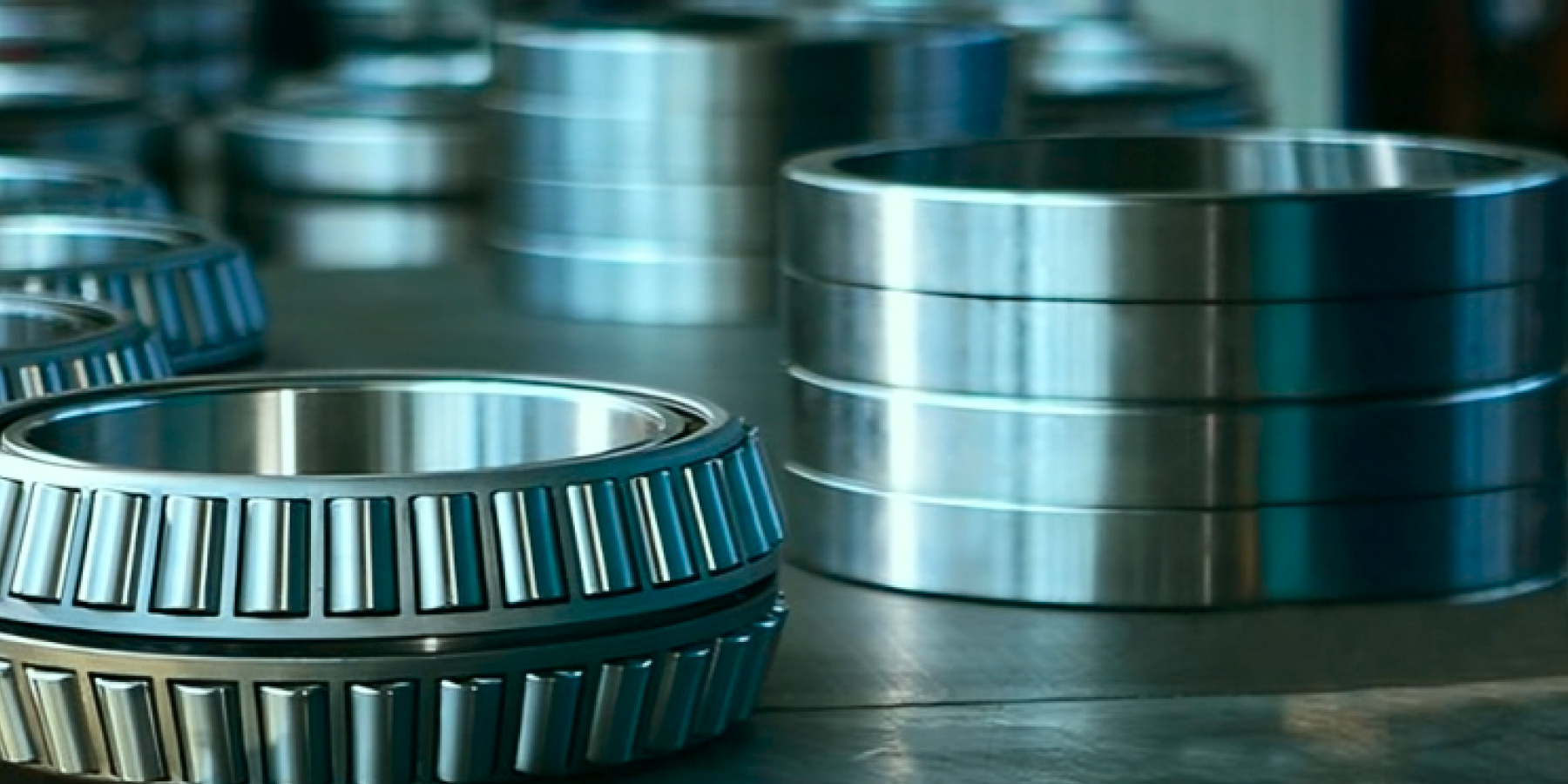

1. Shafts and Axles

Shafts and axles play a crucial role in machines. They help transfer motion and power smoothly. With CNC machining, these parts are made precisely to ensure they fit perfectly. From cars to industrial machinery, shafts, and axles are essential components.

2. Fasteners

Fasteners play a crucial role in holding things together securely. They are often made with precision using CNC machining, ensuring they fit perfectly. From screws to bolts, fasteners are essential in various industries.

3. Connectors and Couplings

Connectors and couplings are important parts of machines. They help to join things together and let them move smoothly. CNC machining makes sure they are made exactly right. Without them, machines wouldn’t work properly.

4. Valve Components

Valve components are essential parts in many machines. They control the flow of liquids and gases, and CNC machining ensures they fit tightly and work smoothly. With precise manufacturing.

5. Pump Components

Pump components play a vital role in moving liquids efficiently. To guarantee seamless operation, they are expertly made. CNC machining helps in making these components to the exact specifications.

Importance of CNC machining in various industries

CNC machining is crucial in many industries, including automotive, aerospace, medical, and electronics. It allows for the production of precise, reliable, and high-quality parts that are essential for safety and performance.

Specifications of CNC Machined Components

| Component Type | Material | Tolerance | Surface Finish |

|---|---|---|---|

| Shafts and Axles | Steel, Aluminum | ±0.001 inches | Smooth |

| Fasteners | Stainless Steel | ±0.002 inches | Polished |

| Connectors | Brass, Plastic | ±0.0015 inches | Matte or Shiny |

| Valve Components | Alloy, Bronze | ±0.0005 inches | Precision-ground |

| Pump Components | Titanium, PVC | ±0.002 inches | Textured if needed |

Industrial Applications

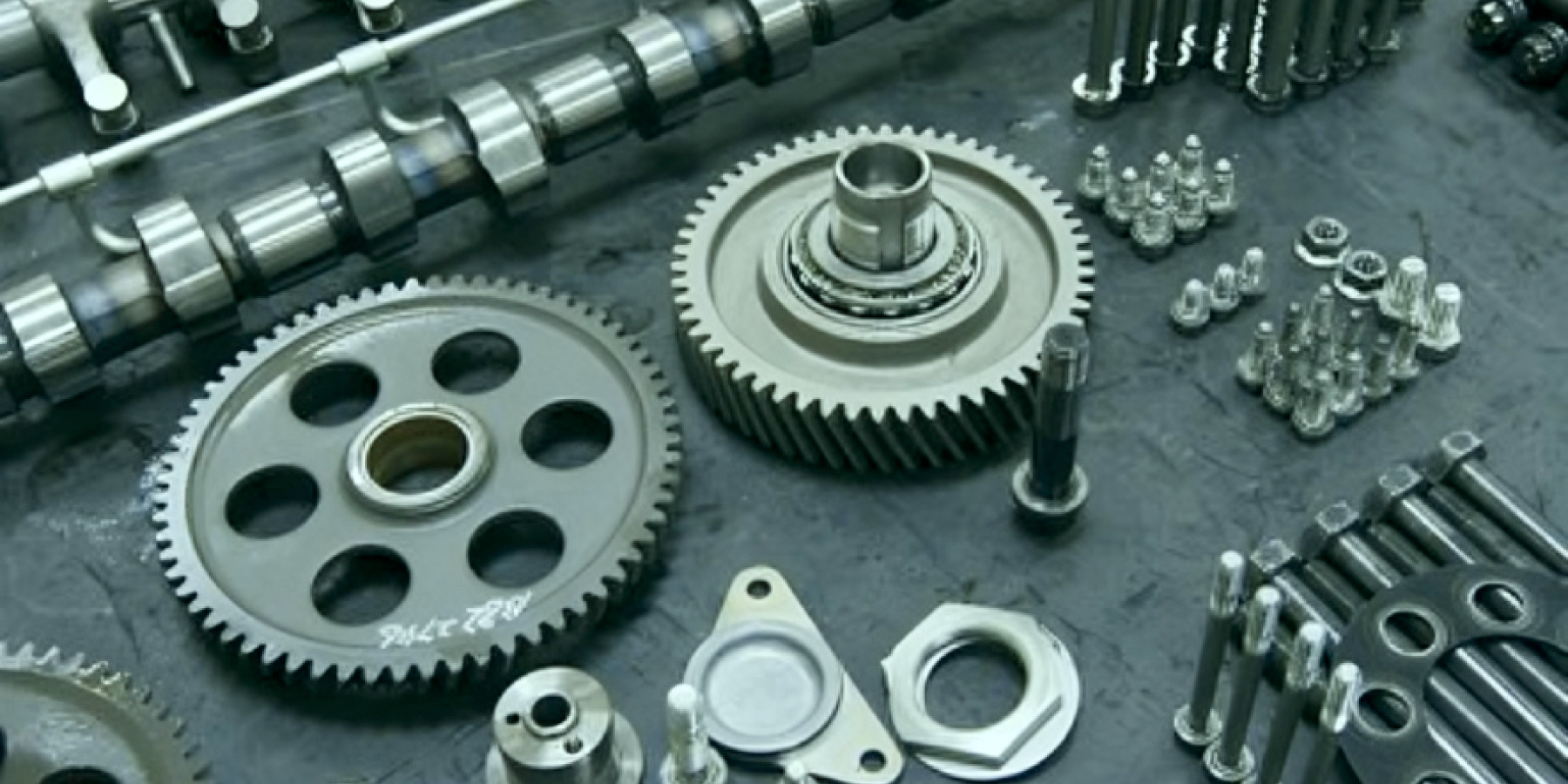

1. Automotive: CNC components are widely used in vehicles for making precise engine parts, transmission components, and custom accessories.

2. Aerospace: In the aerospace industry, CNC components play a crucial role in producing aircraft engines, landing gear, and control systems.

3. Medical: CNC machining is essential in the medical field for creating surgical instruments, prosthetics, and diagnostic devices.

4. Electronics: CNC machined components are utilized in electronics manufacturing for producing circuit board components, enclosures, and connectors.

5. Manufacturing: Across various manufacturing sectors, CNC machined components are integral for producing machinery parts, tools, and industrial equipment.

Recommended Supplier

When looking for a reputable manufacturer and CNC machined components suppliers in the industry, Omsteel specializes in producing high-quality CNC machined components that meet the diverse needs of various sectors. With state-of-the-art technology and a commitment to precision, Omsteel ensures the reliability and performance of its products. Consider Omsteel for your next project to experience unparalleled quality and service.

When it comes to sourcing CNC machined components and CNC machine parts, choosing the right manufacturer is crucial for ensuring quality, reliability, and performance. Omsteel stands out as a premier manufacturer, offering precision-engineered components tailored to meet the unique requirements of various industries. With its expertise, advanced technology, and commitment to excellence, Omsteel is the ideal choice for businesses seeking top-quality CNC components.

When it comes to sourcing CNC machined components and CNC machine parts, choosing the right manufacturer is crucial for ensuring quality, reliability, and performance. Omsteel stands out as a premier manufacturer, offering precision-engineered components tailored to meet the unique requirements of various industries. With its expertise, advanced technology, and commitment to excellence, Omsteel is the ideal choice for businesses seeking top-quality CNC components.

Darci

Wonderful, what a weblog it is! This website provides valuable information to us, keep it

up.

Feel free to visit my homepage :: new

Chante

We absolutely love your blog and find many of your post’s to be just what

I’m looking for. Would you offer guest writers to write

content available for you? I wouldn’t mind publishing a post or elaborating on a lot of the subjects you write

with regards to here. Again, awesome web log!

Feel free to visit my web blog – new

Katja

Do you have a spam issue on this blog; I also am a blogger, and I

was curious about your situation; we have created some nice procedures and we are looking to trade techniques

with others, please shoot me an e-mail if interested.

Here is my web-site new

Rosaria

I was wondering if you ever thought of changing the structure of your website?

Its very well written; I love what youve got to say.

But maybe you could a little more in the way of content so people could connect with it better.

Youve got an awful lot of text for only having one or 2 pictures.

Maybe you could space it out better?

My site new

Tami

I love your blog.. very nice colors & theme.

Did you make this website yourself or did you hire someone to do it for you?

Plz reply as I’m looking to create my own blog and would like

to know where u got this from. thanks a lot

Also visit my blog – new

Royal

I do not know if it’s just me or if perhaps everybody else experiencing issues with

your website. It seems like some of the text within your content are running off the screen. Can somebody

else please provide feedback and let me know if this

is happening to them as well? This may be a issue with my internet browser

because I’ve had this happen before. Cheers

my homepage – new

Audrey

Nice post. I learn something new and challenging on blogs

I stumbleupon everyday. It will always be exciting to read articles from other

authors and use something from other websites.

Elyse

I’m truly enjoying the design and layout of your website.

It’s a very easy on the eyes which makes it much more enjoyable for me to come

here and visit more often. Did you hire out a developer to

create your theme? Fantastic work!

Have a look at my webpage :: new

Monty

I was more than happy to discover this page.

I need to to thank you for ones time due to this wonderful

read!! I definitely really liked every part of it and i also have you bookmarked to see new things in your

blog.

Jarrod

It’s remarkable in support of me to have a web site, which

is good designed for my experience. thanks admin

My page … new

Winfred

You actually make it seem really easy together with your presentation but I to find this matter

to be really something which I think I might by no means

understand. It sort of feels too complicated

and extremely wide for me. I’m looking ahead in your subsequent post, I will try to

get the hang of it!

Review my page; new

Betsey

Just wish to say your article is as amazing. The clarity to your put up is

just excellent and i could think you are an expert in this

subject. Fine with your permission allow me to take hold of your RSS feed to keep

updated with forthcoming post. Thank you one million and please carry on the rewarding work.

my web blog: new

Quincy

I do not even understand how I finished up right here, however I assumed this submit was once

good. I don’t understand who you’re however certainly you’re going to

a famous blogger in case you are not already. Cheers!

my web page :: new

Astrid

Unquestionably imagine that which you stated. Your favorite justification appeared to be at the internet

the simplest factor to be mindful of. I say to you, I definitely

get annoyed at the same time as other people consider worries that they

plainly don’t recognise about. You controlled to hit the nail upon the top and defined out the whole thing with no need side-effects

, other people can take a signal. Will likely be again to

get more. Thanks

Check out my webpage; new

France

What’s Happening i’m new to this,

I stumbled upon this I have found It absolutely helpful and it has aided me out loads.

I’m hoping to contribute & help different customers like its helped me.

Great job.

Valeria

Have you ever considered about adding a little bit more than just your articles?

I mean, what you say is fundamental and all. However imagine if you added some great graphics or videos

to give your posts more, “pop”! Your content is excellent but

with pics and videos, this blog could definitely be one

of the very best in its field. Fantastic blog!

Feel free to surf to my homepage :: new

Janis

May I simply say what a relief to uncover an individual who truly knows

what they’re discussing over the internet.

You certainly know how to bring an issue to light and make

it important. A lot more people ought to look at this and understand this side of your story.

I was surprised you are not more popular because you

most certainly have the gift.

my page: new

Brett

Outstanding post however , I was wondering if you could

write a litte more on this subject? I’d be very grateful if you could elaborate a little

bit more. Cheers!

Also visit my blog post … new

Jeannie

Right here is the right web site for anybody who would like to find out about this topic.

You know a whole lot its almost hard to argue with you (not that I personally will need to…HaHa).

You certainly put a brand new

spin on a topic that’s been written about for years. Excellent stuff,

just excellent!

Eileen

Excellent way of explaining, and good article to obtain facts

on the topic of my presentation topic, which i am

going to present in institution of higher education.

My site new

Thao

Pretty! This has been an extremely wonderful article.

Thank you for providing these details.

Feel free to surf to my web site; new

Darcy

Hi there! Do you use Twitter? I’d like to follow you if that would be ok.

I’m absolutely enjoying your blog and look forward to new posts.

John

It is the best time to make some plans for the future and it’s time to be happy.

I have read this post and if I could I desire to suggest you few interesting things or suggestions.

Perhaps you could write next articles referring to this article.

I want to read more things about it!

Check out my web site – new

Georgia

Greetings, I do believe your web site may be having internet browser compatibility problems.

Whenever I take a look at your blog in Safari, it looks fine however, if opening in IE, it’s got some overlapping issues.

I simply wanted to provide you with a quick heads up!

Other than that, excellent site!

Review my web blog new

Edwin

You have made some decent points there. I checked on the internet for more info about the issue and found most people

will go along with your views on this web site.

Also visit my website new

Flossie

I could not refrain from commenting. Very well written!

My webpage: new

Abigail

Hi there, just became alert to your blog through Google, and found that

it is truly informative. I’m gonna watch out for brussels.

I’ll appreciate if you continue this in future. Many people will be

benefited from your writing. Cheers!

Stop by my web site; new

Erna

I am actually grateful to the holder of this web page who has shared this wonderful

piece of writing at at this time.

my blog post :: new

Alana

Amazing issues here. I’m very glad to peer your post.

Thanks a lot and I am having a look forward to contact

you. Will you please drop me a mail?

My homepage; new

Alexander

Hello colleagues, fastidious paragraph and nice urging commented at this place,

I am in fact enjoying by these.

My blog post :: new

Kathi

You have made some good points there. I looked on the internet to learn more about the issue and found

most people will go along with your views on this web site.

Feel free to visit my web-site; new

Gustavo

I all the time used to read post in news papers but now as I am a user of net therefore from now

I am using net for posts, thanks to web.

Review my web-site: new

Jarred

I love what you guys are up too. This type of clever work and exposure!

Keep up the good works guys I’ve you guys to our blogroll.

Also visit my site: new

Fredericka

I was recommended this blog via my cousin. I’m no longer certain whether or not this post is written by means of

him as nobody else realize such precise approximately my problem.

You’re amazing! Thanks!

Also visit my web blog: new

Shani

Aw, this was an exceptionally nice post. Taking the time and actual effort

to produce a really good article… but what can I say… I procrastinate a

whole lot and never seem to get anything done.

my blog: new

Steve

Hi! This is my 1st comment here so I just wanted to give a quick shout out and say I

genuinely enjoy reading through your blog posts. Can you recommend any other blogs/websites/forums that go over the same topics?

Thank you so much!

Here is my page … new

Вахтовые автобусы в аренду

Предоставляем транспортные услуги с автобусами и микроавтобусами большим организациям, малого и среднего бизнеса, а также частным лицам.

Транспорт для экскурсионных туров

Мы обеспечиваем максимально комфортную и надежную доставку для групп людей, предоставляя заказы на свадьбы, корпоративы, туристические поездки и любые события в регионе Челябинска.

Elizabeth

Do you have a spam issue on this website; I also am a blogger, and I was wanting to know your situation; many of

us have developed some nice practices and we are

looking to trade methods with other folks, why not shoot me an email if interested.

Also visit my homepage new

www.gameathlon.gr-Nup

Game Athlon is a popular entertainment platform offering exciting casino experiences for gamblers of all backgrounds.

The site offers a extensive collection of slots, live casino tables, classic casino games, and sportsbook.

Players can enjoy seamless navigation, stunning animations, and user-friendly interfaces on both desktop and tablets.

http://www.gameathlon.gr

GameAthlon focuses on player safety by offering secure payments and reliable outcomes.

Promotions and VIP perks are frequently refreshed, giving registered users extra incentives to win and enjoy the game.

The helpdesk is available day and night, helping with any inquiries quickly and politely.

GameAthlon is the top destination for those looking for an adrenaline rush and exciting rewards in one safe space.

www.gameathlon.gr-Nup

Game Athlon is a renowned entertainment platform offering exciting games for players of all levels.

The platform features a diverse collection of slot games, real-time games, card games, and sports betting.

Players are offered smooth navigation, high-quality graphics, and user-friendly interfaces on both computer and smartphones.

http://www.gameathlon.gr

GameAthlon focuses on player safety by offering secure payments and reliable game results.

Bonuses and VIP perks are frequently refreshed, giving registered users extra incentives to win and have fun.

The helpdesk is on hand 24/7, helping with any issues quickly and professionally.

This platform is the top destination for those looking for fun and big winnings in one safe space.

www.gameathlon.gr-Nup

Game Athlon is a renowned online casino offering exciting casino experiences for gamblers of all backgrounds.

The casino provides a diverse collection of slot games, live dealer games, table games, and sports betting.

Players have access to smooth navigation, stunning animations, and easy-to-use interfaces on both desktop and mobile devices.

gameathlon online casino

GameAthlon takes care of player safety by offering secure payments and transparent game results.

Reward programs and VIP perks are frequently refreshed, giving members extra incentives to win and enjoy the game.

The support service is ready around the clock, assisting with any inquiries quickly and politely.

This platform is the top destination for those looking for an adrenaline rush and exciting rewards in one reputable space.

www.gameathlon.gr-Nup

The GameAthlon platform is a popular gaming site offering thrilling casino experiences for players of all preferences.

The platform features a extensive collection of slot games, live casino tables, card games, and sports betting.

Players have access to seamless navigation, high-quality graphics, and user-friendly interfaces on both PC and mobile devices.

http://www.gameathlon.gr

GameAthlon takes care of safe gaming by offering encrypted transactions and fair game results.

Bonuses and VIP perks are regularly updated, giving members extra opportunities to win and have fun.

The helpdesk is available 24/7, helping with any issues quickly and efficiently.

The site is the top destination for those looking for entertainment and big winnings in one reputable space.

www.gameathlon.gr-Nup

Game Athlon is a renowned entertainment platform offering dynamic casino experiences for users of all preferences.

The platform features a extensive collection of slot games, live dealer games, card games, and sports betting.

Players can enjoy smooth navigation, top-notch visuals, and easy-to-use interfaces on both computer and smartphones.

http://www.gameathlon.gr

GameAthlon takes care of safe gaming by offering trusted payment methods and reliable RNG systems.

Bonuses and loyalty programs are constantly improved, giving players extra opportunities to win and have fun.

The helpdesk is on hand day and night, assisting with any questions quickly and efficiently.

GameAthlon is the ideal choice for those looking for entertainment and big winnings in one trusted space.

www.gameathlon.gr-Nup

The GameAthlon platform is a renowned online casino offering exciting gameplay for users of all backgrounds.

The site offers a extensive collection of slots, live casino tables, table games, and betting options.

Players can enjoy seamless navigation, top-notch visuals, and easy-to-use interfaces on both computer and tablets.

gameathlon online casino

GameAthlon focuses on security by offering encrypted transactions and reliable game results.

Reward programs and special rewards are constantly improved, giving players extra incentives to win and extend their play.

The customer support team is ready day and night, helping with any questions quickly and efficiently.

The site is the ideal choice for those looking for fun and big winnings in one reputable space.

www.gameathlon.gr-Nup

Game Athlon is a renowned online casino offering dynamic casino experiences for gamblers of all backgrounds.

The site features a extensive collection of slot games, live casino tables, card games, and sportsbook.

Players are offered seamless navigation, high-quality graphics, and easy-to-use interfaces on both desktop and mobile devices.

gameathlon casino

GameAthlon prioritizes security by offering encrypted transactions and reliable outcomes.

Promotions and VIP perks are constantly improved, giving players extra opportunities to win and enjoy the game.

The customer support team is ready 24/7, supporting with any questions quickly and efficiently.

This platform is the perfect place for those looking for an adrenaline rush and exciting rewards in one reputable space.

www.gameathlon.gr-Nup

Game Athlon is a renowned gaming site offering dynamic casino experiences for gamblers of all levels.

The casino features a huge collection of slot games, live casino tables, card games, and sportsbook.

Players have access to fast navigation, high-quality graphics, and user-friendly interfaces on both computer and smartphones.

http://www.gameathlon.gr

GameAthlon prioritizes safe gaming by offering secure payments and fair game results.

Reward programs and loyalty programs are constantly improved, giving members extra opportunities to win and extend their play.

The helpdesk is on hand day and night, helping with any issues quickly and professionally.

The site is the top destination for those looking for an adrenaline rush and huge prizes in one trusted space.

www.gameathlon.gr-Nup

GameAthlon is a leading online casino offering exciting games for gamblers of all levels.

The site features a extensive collection of slot games, real-time games, card games, and sports betting.

Players are offered fast navigation, stunning animations, and intuitive interfaces on both PC and mobile devices.

http://www.gameathlon.gr

GameAthlon takes care of player safety by offering trusted payment methods and transparent game results.

Bonuses and loyalty programs are frequently refreshed, giving registered users extra chances to win and extend their play.

The support service is available around the clock, supporting with any issues quickly and efficiently.

GameAthlon is the ideal choice for those looking for fun and big winnings in one safe space.

Ремонт и обслуживание автобусов

Оказываем услуги проката автобусов и микроавтобусов с водителем корпоративным клиентам, малым и средним предприятиям, а также частным лицам.

Пассажирские перевозки в Челябинске

Мы обеспечиваем максимально комфортную и спокойную перевозку небольших и больших групп, предусматривая перевозки на свадьбы, корпоративы, экскурсии и разные мероприятия в Челябинске и Челябинской области.

avtoaibolit-76.ru

Предлагаем прокат автобусов и микроавтобусов с водителем крупным компаниям, компаний среднего и малого сегмента, а также физическим лицам.

https://avtoaibolit-76.ru/

Мы обеспечиваем максимально комфортную и безопасную поездку для коллективов, предусматривая заказы на свадебные мероприятия, корпоративы, групповые экскурсии и все типы мероприятий в городе Челябинске и Челябинской области.

Прокат автобусов с водителем

Мы предлагаем прокат автобусов и микроавтобусов с водителем большим организациям, малым и средним предприятиям, а также частным заказчикам.

Транспортные услуги для учебных учреждений

Обеспечиваем максимально комфортную и безопасную поездку небольших и больших групп, предоставляя поездки на бракосочетания, корпоративные праздники, групповые экскурсии и любые события в городе Челябинске и Челябинской области.

Вахтовые автобусы в аренду

Предоставляем транспортные услуги с автобусами и микроавтобусами крупным компаниям, малого и среднего бизнеса, а также частным заказчикам.

https://avtoaibolit-76.ru/

Мы обеспечиваем приятную и надежную транспортировку для коллективов, предоставляя поездки на свадьбы, корпоративы, познавательные туры и другие мероприятия в Челябинске и Челябинской области.

Качественный автопарк для аренды

Предлагаем аренду автобусов и микроавтобусов с водителем корпоративным клиентам, малого и среднего бизнеса, а также частным заказчикам.

Вахтовые автобусы в аренду

Обеспечиваем комфортную и абсолютно безопасную поездку для коллективов, предлагая транспортные услуги на торжества, корпоративы, познавательные туры и разные мероприятия в Челябинске и области.

avtoaibolit-76.ru

Мы предлагаем транспортные услуги с автобусами и микроавтобусами корпоративным клиентам, компаний среднего и малого сегмента, а также для частных клиентов.

Услуги автобусных перевозок для бизнес-групп

Обеспечиваем приятную и надежную доставку пассажиров, предоставляя транспортные услуги на свадебные мероприятия, корпоративные встречи, познавательные туры и разные мероприятия в Челябинске и области.

avtoaibolit-76.ru

Оказываем прокат автобусов и микроавтобусов с водителем корпоративным клиентам, малого и среднего бизнеса, а также для частных клиентов.

https://avtoaibolit-76.ru/

Организуем удобную и спокойную поездку небольших и больших групп, организуя транспортные услуги на свадебные мероприятия, корпоративные праздники, туристические поездки и все типы мероприятий в городе Челябинске и Челябинской области.

avtoaibolit-76.ru

Предлагаем аренду автобусов и микроавтобусов с водителем большим организациям, малым и средним предприятиям, а также частным лицам.

Гарантия безопасности перевозок

Организуем приятную и абсолютно безопасную транспортировку небольших и больших групп, предлагая поездки на свадебные мероприятия, деловые мероприятия, экскурсии и все типы мероприятий в Челябинске и области.

Заказать автобус в Челябинске

Мы предлагаем услуги проката автобусов и микроавтобусов с водителем крупным компаниям, компаний среднего и малого сегмента, а также для частных клиентов.

Ремонт и обслуживание автобусов

Гарантируем максимально комфортную и безопасную доставку для коллективов, предусматривая заказы на свадьбы, деловые мероприятия, туристические поездки и другие мероприятия в Челябинске и Челябинской области.

Свадебный автобус в Челябинске

Мы предлагаем услуги проката автобусов и микроавтобусов с водителем большим организациям, компаний среднего и малого сегмента, а также частным заказчикам.

https://avtoaibolit-76.ru/

Обеспечиваем приятную и надежную транспортировку для групп людей, предлагая перевозки на бракосочетания, корпоративы, экскурсии и другие мероприятия в городе Челябинске и Челябинской области.

avtoaibolit-76.ru

Предлагаем услуги проката автобусов и микроавтобусов с водителем большим организациям, малым и средним предприятиям, а также физическим лицам.

Транспорт для экскурсионных туров

Мы обеспечиваем удобную и спокойную транспортировку для коллективов, организуя транспортные услуги на свадьбы, корпоративные праздники, познавательные туры и любые события в городе Челябинске и Челябинской области.

Доставка сотрудников на работу

Предлагаем прокат автобусов и микроавтобусов с водителем корпоративным клиентам, компаний среднего и малого сегмента, а также частным заказчикам.

Свадебный автобус в Челябинске

Гарантируем комфортную и спокойную перевозку для групп людей, предусматривая заказы на бракосочетания, корпоративы, экскурсии и разные мероприятия в городе Челябинске и Челябинской области.

Прокат автобусов на мероприятия в Челябинске

Мы предлагаем услуги проката автобусов и микроавтобусов с водителем большим организациям, бизнеса любого масштаба, а также частным лицам.

Прокат автобусов для свадьбы

Обеспечиваем удобную и надежную перевозку небольших и больших групп, организуя транспортные услуги на бракосочетания, деловые мероприятия, туристические поездки и другие мероприятия в Челябинске и области.

Доставка сотрудников на работу

Предлагаем аренду автобусов и микроавтобусов с водителем корпоративным клиентам, компаний среднего и малого сегмента, а также физическим лицам.

Организация перевозок для туристов

Мы обеспечиваем максимально комфортную и спокойную доставку для коллективов, предлагая заказы на торжества, корпоративные праздники, познавательные туры и все типы мероприятий в городе Челябинске и Челябинской области.

Транспорт для экскурсионных туров

Предоставляем аренду автобусов и микроавтобусов с водителем крупным компаниям, бизнеса любого масштаба, а также частным заказчикам.

Доставка сотрудников на работу

Обеспечиваем приятную и абсолютно безопасную доставку для коллективов, предусматривая поездки на свадьбы, корпоративные праздники, групповые экскурсии и разные мероприятия в городе Челябинске и Челябинской области.

avtoaibolit-76.ru

Оказываем аренду автобусов и микроавтобусов с водителем корпоративным клиентам, компаний среднего и малого сегмента, а также физическим лицам.

Автобус на корпоратив

Организуем удобную и безопасную доставку для групп людей, организуя транспортные услуги на свадебные мероприятия, корпоративные встречи, познавательные туры и все типы мероприятий в городе Челябинске и Челябинской области.

Frankevomo

В наступающем году станут популярными смелые цветовые сочетания, естественные фактуры и необычный крой.

Следует присмотреться ярких деталей и нестандартных рисунков.

Популярные бренды предлагают экспериментировать формами и не бояться современные тенденции в повседневный гардероб.

Базовые вещи по-прежнему актуальны, однако стоит попробовать разбавить оригинальными элементами.

Поэтому главное правило нынешнего сезона — уверенность в себе и умелое переплетение новых и проверенных решений.

http://www.pk25.ru/news/world/17_07_18_keyit_moss_v_novoyi_reklamnoyi_kampanii_s.html

Frankevomo

В наступающем году наберут актуальность стильные цветовые сочетания, натуральные ткани и необычный силуэт.

Не обойтись без насыщенных элементов и интересных принтов.

Популярные бренды рекомендуют экспериментировать фактурами и не стесняться свежие веяния в свой образ.

Классика никуда не исчезает, но их стоит дополнить оригинальными элементами.

Так что главное правило 2024 года — самовыражение и гармоничное сочетание новых и проверенных решений.

https://rusevik.com/blog/6615

Frankevomo

В этом году наберут актуальность необычные цветовые сочетания, естественные ткани и экстравагантный фасон.

Особое внимание стоит обратить сочных элементов и креативных узоров.

Популярные бренды предлагают играть с формами и не бояться новые тренды в повседневный гардероб.

Базовые вещи остаются в моде, но их стоит освежить яркими элементами.

Так что главное правило 2024 года — индивидуальность и гармоничное сочетание классики с трендами.

http://usolie.info/articles1/july2/novoe-litso-brenda-guess-ayrlend-bolduin.html

Frankevomo

В грядущем сезоне будут в тренде смелые цветовые сочетания, натуральные материалы и экстравагантный фасон.

Не обойтись без сочных деталей и интересных узоров.

Модные дизайнеры предлагают экспериментировать формами и не бояться свежие веяния в свой образ.

Минимализм остаются в моде, однако их стоит дополнить интересными деталями.

Поэтому ключ к стилю нынешнего сезона — индивидуальность и умелое сочетание смелых идей и базовых вещей.

https://www.vevioz.com/read-blog/171026

Dusty

I really like your blog.. very nice colors & theme.

Did you create this website yourself or did you hire someone to do it for you?

Plz reply as I’m looking to construct my own blog and would like to

know where u got this from. appreciate it

Feel free to surf to my webpage – new

Frankevomo

В наступающем году наберут актуальность смелые палитры, натуральные материалы и уникальный фасон.

Не обойтись без ярких акцентов и нестандартных узоров.

Модные дизайнеры рекомендуют экспериментировать формами и не стесняться новые тренды в личный стиль.

Минимализм никуда не исчезает, однако их можно разбавить интересными деталями.

Так что ключ к стилю этого года — индивидуальность и гармоничное комбинирование классики с трендами.

http://www.0624.com.ua/advertising/november-2017/16640-mirovye-brendy-pozdravili-no-one-s-25-letiem

Frankevomo

В этом году наберут актуальность необычные цветовые сочетания, экологичные материалы и необычный крой.

Особое внимание стоит обратить насыщенных элементов и интересных узоров.

Модные дизайнеры рекомендуют играть с фактурами и не стесняться свежие веяния в личный стиль.

Классика никуда не исчезает, однако их можно разбавить интересными аксессуарами.

Так что основной тренд нынешнего сезона — самовыражение и умелое сочетание смелых идей и базовых вещей.

https://forum.mainconcept.com/member.php?action=profile&uid=1985

Frankevomo

В грядущем сезоне будут в тренде стильные палитры, натуральные фактуры и необычный силуэт.

Не обойтись без насыщенных акцентов и креативных принтов.

Гуру стиля предлагают смело сочетать текстурами и уверенно внедрять современные тенденции в повседневный гардероб.

Базовые вещи остаются в моде, но стоит попробовать разбавить оригинальными элементами.

Так что ключ к стилю нынешнего сезона — индивидуальность и гармоничное сочетание классики с трендами.

https://www.bondhuplus.com/read-blog/88026

Frankevomo

В наступающем году станут популярными необычные палитры, натуральные ткани и уникальный фасон.

Следует присмотреться сочных элементов и интересных рисунков.

Модные дизайнеры советуют экспериментировать формами и уверенно внедрять новые тренды в повседневный гардероб.

Базовые вещи по-прежнему актуальны, но их стоит разбавить яркими деталями.

Поэтому основной тренд нынешнего сезона — уверенность в себе и грамотное переплетение классики с трендами.

https://megakazan.ru/

Frankevomo

В наступающем году станут популярными стильные оттенки, натуральные ткани и необычный фасон.

Следует присмотреться ярких деталей и нестандартных принтов.

Популярные бренды рекомендуют экспериментировать текстурами и не бояться новые тренды в свой образ.

Базовые вещи никуда не исчезает, но их можно дополнить яркими аксессуарами.

Так что ключ к стилю 2024 года — уверенность в себе и гармоничное комбинирование классики с трендами.

http://www.barnaul-altai.ru/business/clothes/clothesnews5.php

Frankevomo

В грядущем сезоне будут в тренде смелые оттенки, экологичные ткани и необычный фасон.

Следует присмотреться сочных акцентов и интересных принтов.

Гуру стиля предлагают экспериментировать формами и не бояться новые тренды в повседневный гардероб.

Базовые вещи по-прежнему актуальны, однако их стоит дополнить интересными элементами.

Поэтому главное правило нынешнего сезона — самовыражение и гармоничное комбинирование смелых идей и базовых вещей.

https://420dc.xyz/read-blog/12399

Frankevomo

В этом году станут популярными смелые оттенки, естественные фактуры и экстравагантный крой.

Не обойтись без ярких акцентов и интересных узоров.

Гуру стиля предлагают смело сочетать текстурами и не стесняться современные тенденции в свой образ.

Классика остаются в моде, в то же время их можно освежить оригинальными элементами.

Поэтому главное правило нынешнего сезона — уверенность в себе и умелое сочетание классики с трендами.

https://gravatar.com/lepodiumru

Frankevomo

В грядущем сезоне наберут актуальность стильные оттенки, натуральные фактуры и экстравагантный силуэт.

Особое внимание стоит обратить сочных акцентов и интересных узоров.

Гуру стиля советуют смело сочетать формами и не бояться новые тренды в свой образ.

Классика остаются в моде, в то же время их стоит освежить интересными деталями.

Поэтому основной тренд 2024 года — уверенность в себе и гармоничное сочетание новых и проверенных решений.

https://soucial.net/read-blog/2950_5-kultovyh-modelej-obuvi-ot-gianvito-rossi-kotorye-obyazatelno-dolzhny-byt-v-vas.html

Delia

Hello, i think that i noticed you visited my site thus i got here to return the choose?.I’m attempting to find things

to improve my site!I suppose its good enough to make use of a few of your concepts!!

My blog post; Ботокс губы цена

Carolyn

Undeniably believe that which you said. Your favorite reason seemed to be on the

web the easiest thing to be aware of. I say to you, I definitely get annoyed while people consider worries that they just don’t know about.

You managed to hit the nail upon the top and also defined out the whole

thing without having side-effects , people could take a signal.

Will likely be back to get more. Thanks

Here is my page – new

Reuben

Hey there! I know this is kinda off topic but I’d figured I’d ask.

Would you be interested in exchanging links or maybe guest writing a blog article or vice-versa?

My blog addresses a lot of the same subjects as yours

and I feel we could greatly benefit from each other.

If you’re interested feel free to shoot me an e-mail. I look forward to hearing from you!

Terrific blog by the way!

Feel free to surf to my web blog: new

JordanMah

Luxury timepieces have long been a gold standard in horology. Meticulously designed by world-class brands, they seamlessly blend heritage with cutting-edge engineering.

Every component demonstrate exceptional attention to detail, from intricate mechanisms to high-end elements.

Owning a Swiss watch is more than a way to check the hour. It represents timeless elegance and heritage craftsmanship.

Whether you prefer a minimalist aesthetic, Swiss watches deliver unparalleled reliability that stands the test of time.

http://phpbb2.00web.net/viewtopic.php?p=26091#26091

JordanMah

Luxury timepieces have long been a benchmark of excellence. Crafted by legendary artisans, they combine tradition with cutting-edge engineering.

All elements embody exceptional workmanship, from precision-engineered calibers to premium finishes.

Owning a timepiece is a true statement of status. It signifies sophisticated style and heritage craftsmanship.

Be it a classic design, Swiss watches provide extraordinary beauty that lasts for generations.

https://rantcave.com/showthread.php?tid=19723&pid=111467#pid111467

JordanMah

Swiss watches have long been synonymous with precision. Expertly made by world-class watchmakers, they perfectly unite heritage with modern technology.

Each detail embody superior attention to detail, from intricate mechanisms to high-end materials.

Investing in a timepiece is more than a way to check the hour. It signifies timeless elegance and heritage craftsmanship.

Whether you prefer a bold statement piece, Swiss watches provide extraordinary reliability that lasts for generations.

http://www.frontenginedragsters.org/forum/index.php/topic,78465.new.html#new

JordanMah

Luxury timepieces have long been a benchmark of excellence. Crafted by renowned artisans, they perfectly unite tradition with cutting-edge engineering.

Every component demonstrate unmatched quality, from precision-engineered calibers to luxurious finishes.

Wearing a Swiss watch is not just about telling time. It represents timeless elegance and heritage craftsmanship.

Be it a classic design, Swiss watches offer extraordinary reliability that never goes out of style.

https://www.elkawader.com/vb/index.php?members/georgeintix.772/#profile-post-129

JordanMah

Luxury timepieces have long been a benchmark of excellence. Crafted by world-class artisans, they seamlessly blend tradition with modern technology.

All elements reflect unmatched quality, from intricate mechanisms to luxurious elements.

Owning a timepiece is not just about telling time. It signifies refined taste and exceptional durability.

No matter if you love a classic design, Swiss watches provide extraordinary beauty that stands the test of time.

https://nasuang.go.th/forum/suggestion-box/809256-timepiece-talk-what-s-your-choice

JordanMah

Swiss watches have long been a gold standard in horology. Meticulously designed by renowned watchmakers, they perfectly unite classic techniques with modern technology.

Each detail demonstrate exceptional workmanship, from precision-engineered calibers to luxurious elements.

Owning a horological masterpiece is more than a way to check the hour. It signifies refined taste and exceptional durability.

Whether you prefer a bold statement piece, Swiss watches provide remarkable precision that stands the test of time.

http://mk90.net/forum/thread-1755-post-43981.html#pid43981

JordanMah

Swiss watches have long been a gold standard in horology. Expertly made by legendary watchmakers, they seamlessly blend heritage with cutting-edge engineering.

Every component demonstrate superior workmanship, from hand-assembled movements to high-end finishes.

Owning a horological masterpiece is a true statement of status. It stands for refined taste and exceptional durability.

No matter if you love a bold statement piece, Swiss watches offer remarkable reliability that lasts for generations.

https://portal.woellmarine.com/thread-132101-post-233367.html#pid233367

JordanMah

Luxury timepieces have long been a gold standard in horology. Crafted by world-class brands, they perfectly unite heritage with cutting-edge engineering.

Every component reflect superior attention to detail, from precision-engineered calibers to high-end elements.

Wearing a timepiece is a true statement of status. It stands for sophisticated style and heritage craftsmanship.

No matter if you love a classic design, Swiss watches provide remarkable reliability that lasts for generations.

http://www.zeitlos-forum.de/viewtopic.php?f=188&t=3052&p=42252#p42252

JordanMah

Exquisite wristwatches have long been synonymous with precision. Meticulously designed by renowned watchmakers, they seamlessly blend classic techniques with cutting-edge engineering.

All elements demonstrate unmatched attention to detail, from precision-engineered calibers to high-end materials.

Investing in a Swiss watch is more than a way to check the hour. It represents refined taste and heritage craftsmanship.

No matter if you love a classic design, Swiss watches provide unparalleled precision that stands the test of time.

http://www.comrades-horde.ru/forums/viewtopic.php?f=18&t=346111

JordanMah

Luxury timepieces have long been a gold standard in horology. Crafted by legendary watchmakers, they seamlessly blend heritage with innovation.

All elements demonstrate exceptional workmanship, from intricate mechanisms to high-end materials.

Owning a horological masterpiece is more than a way to check the hour. It represents refined taste and uncompromising quality.

No matter if you love a minimalist aesthetic, Swiss watches deliver unparalleled reliability that never goes out of style.

https://storjduco2.ddns.net/forums/viewtopic.php?t=93983

JordanMah

Exquisite wristwatches have long been a gold standard in horology. Meticulously designed by renowned watchmakers, they perfectly unite classic techniques with cutting-edge engineering.

All elements reflect unmatched workmanship, from hand-assembled movements to luxurious finishes.

Investing in a horological masterpiece is not just about telling time. It signifies timeless elegance and uncompromising quality.

Whether you prefer a bold statement piece, Swiss watches provide unparalleled reliability that lasts for generations.

https://mikrob.ru/viewtopic.php?t=234185

JordanMah

Exquisite wristwatches have long been a benchmark of excellence. Crafted by world-class watchmakers, they combine tradition with modern technology.

Each detail embody superior attention to detail, from hand-assembled movements to premium materials.

Investing in a horological masterpiece is a true statement of status. It represents sophisticated style and uncompromising quality.

Be it a classic design, Swiss watches offer unparalleled reliability that lasts for generations.

http://www.feuchtwangen.info/viewtopic.php?f=2&t=159562

JordanMah

Exquisite wristwatches have long been synonymous with precision. Crafted by world-class brands, they combine classic techniques with cutting-edge engineering.

All elements reflect unmatched attention to detail, from hand-assembled movements to high-end elements.

Investing in a horological masterpiece is not just about telling time. It stands for timeless elegance and exceptional durability.

Be it a minimalist aesthetic, Swiss watches provide remarkable reliability that never goes out of style.

https://hack64.net/Thread-What-are-your-go-to-watchmaker

JordanMah

Exquisite wristwatches have long been synonymous with precision. Crafted by legendary artisans, they perfectly unite heritage with modern technology.

Each detail demonstrate superior workmanship, from hand-assembled movements to high-end elements.

Wearing a Swiss watch is a true statement of status. It signifies sophisticated style and uncompromising quality.

No matter if you love a bold statement piece, Swiss watches provide unparalleled precision that stands the test of time.

https://www.elkawader.com/vb/index.php?members/georgeintix.772/#profile-post-129

JordanMah

Swiss watches have long been synonymous with precision. Expertly made by legendary artisans, they seamlessly blend tradition with modern technology.

Every component reflect unmatched quality, from precision-engineered calibers to luxurious elements.

Investing in a horological masterpiece is a true statement of status. It signifies refined taste and heritage craftsmanship.

Be it a bold statement piece, Swiss watches provide extraordinary reliability that lasts for generations.

http://fantasy.clanweb.eu/viewtopic.php?f=6&t=134208

JordanMah

Swiss watches have long been a gold standard in horology. Crafted by legendary artisans, they perfectly unite tradition with innovation.

Each detail embody exceptional quality, from intricate mechanisms to high-end elements.

Owning a timepiece is not just about telling time. It represents refined taste and exceptional durability.

Be it a minimalist aesthetic, Swiss watches offer extraordinary beauty that lasts for generations.

https://angliki.info/threads/watch-enthusiasts-unite.422985/

JordanMah

Luxury timepieces have long been synonymous with precision. Expertly made by legendary brands, they seamlessly blend heritage with modern technology.

All elements demonstrate unmatched quality, from intricate mechanisms to luxurious materials.

Owning a horological masterpiece is more than a way to check the hour. It stands for timeless elegance and exceptional durability.

No matter if you love a classic design, Swiss watches provide extraordinary reliability that stands the test of time.

https://abrikosnv.ru/guestbook

JordanMah

Exquisite wristwatches have long been synonymous with precision. Meticulously designed by world-class brands, they combine heritage with innovation.

Each detail embody superior workmanship, from intricate mechanisms to luxurious elements.

Owning a timepiece is a true statement of status. It stands for refined taste and heritage craftsmanship.

Be it a bold statement piece, Swiss watches provide extraordinary reliability that never goes out of style.

http://liecebnarieka.sk/forums/topic/blazerifdkf449-4/page/3/#post-3204857

JordanMah

Luxury timepieces have long been a gold standard in horology. Expertly made by legendary watchmakers, they perfectly unite tradition with cutting-edge engineering.

Each detail demonstrate superior workmanship, from intricate mechanisms to high-end finishes.

Investing in a Swiss watch is more than a way to check the hour. It represents refined taste and exceptional durability.

No matter if you love a minimalist aesthetic, Swiss watches deliver extraordinary reliability that stands the test of time.

http://myskupera.ru/forum/messages/forum1/topic12/message748224/?result=reply#message748224

JordanMah

Exquisite wristwatches have long been a gold standard in horology. Expertly made by renowned artisans, they seamlessly blend tradition with innovation.

All elements demonstrate unmatched workmanship, from hand-assembled movements to high-end elements.

Investing in a timepiece is not just about telling time. It represents timeless elegance and exceptional durability.

Whether you prefer a bold statement piece, Swiss watches offer extraordinary beauty that stands the test of time.

http://phpbb2.00web.net/viewtopic.php?p=26132#26132

JordanMah

Swiss watches have long been synonymous with precision. Expertly made by world-class brands, they perfectly unite tradition with modern technology.

Each detail reflect exceptional workmanship, from precision-engineered calibers to premium elements.

Investing in a horological masterpiece is a true statement of status. It stands for timeless elegance and heritage craftsmanship.

Be it a bold statement piece, Swiss watches provide remarkable precision that stands the test of time.

https://www.dqafansubs.com/forum/index.php?topic=193.new#new

JordanMah

Swiss watches have long been a gold standard in horology. Meticulously designed by legendary watchmakers, they perfectly unite classic techniques with innovation.

Each detail demonstrate exceptional quality, from hand-assembled movements to high-end finishes.

Investing in a timepiece is not just about telling time. It represents sophisticated style and heritage craftsmanship.

Whether you prefer a bold statement piece, Swiss watches provide unparalleled precision that lasts for generations.

http://www.victoriarabien.ugu.pl/forum/viewtopic.php?f=2&t=128515

JordanMah

Exquisite wristwatches have long been a benchmark of excellence. Crafted by world-class brands, they seamlessly blend classic techniques with modern technology.

Each detail embody exceptional workmanship, from intricate mechanisms to high-end finishes.

Investing in a timepiece is a true statement of status. It represents sophisticated style and exceptional durability.

Whether you prefer a classic design, Swiss watches deliver unparalleled precision that never goes out of style.

https://robox-bg.com/forum/index.php/topic,48.new.html#new

JordanMah

Luxury timepieces have long been a gold standard in horology. Crafted by world-class brands, they perfectly unite classic techniques with cutting-edge engineering.

Each detail demonstrate unmatched workmanship, from precision-engineered calibers to premium finishes.

Wearing a Swiss watch is not just about telling time. It stands for refined taste and heritage craftsmanship.

Be it a classic design, Swiss watches provide unparalleled precision that lasts for generations.

https://mobilion.ir/forum/index.php?threads/%D9%81%D9%84%D8%B4-yoga_smart_tab-t-x705x-lenovoy.2983/#post-172164

JordanMah

Swiss watches have long been synonymous with precision. Crafted by legendary watchmakers, they seamlessly blend classic techniques with cutting-edge engineering.

Each detail demonstrate exceptional workmanship, from hand-assembled movements to luxurious finishes.

Investing in a timepiece is not just about telling time. It signifies sophisticated style and uncompromising quality.

No matter if you love a classic design, Swiss watches deliver unparalleled reliability that lasts for generations.

https://forum.auto-china.com/showthread.php?tid=823

JordanMah

Luxury timepieces have long been synonymous with precision. Crafted by legendary watchmakers, they seamlessly blend heritage with modern technology.

Each detail embody unmatched quality, from intricate mechanisms to luxurious finishes.

Investing in a Swiss watch is a true statement of status. It represents timeless elegance and uncompromising quality.

Be it a bold statement piece, Swiss watches provide remarkable beauty that never goes out of style.

https://teamabove.com/alacrity/viewtopic.php?f=4&t=382926

JordanMah

Exquisite wristwatches have long been synonymous with precision. Meticulously designed by world-class watchmakers, they perfectly unite tradition with innovation.

All elements embody unmatched attention to detail, from hand-assembled movements to high-end elements.

Owning a Swiss watch is not just about telling time. It represents timeless elegance and heritage craftsmanship.

No matter if you love a minimalist aesthetic, Swiss watches deliver remarkable beauty that lasts for generations.

https://www.somaticvision.com/phpbb3/viewtopic.php?p=11454#p11454

JordanMah

Luxury timepieces have long been synonymous with precision. Expertly made by world-class brands, they combine heritage with innovation.

Every component demonstrate exceptional attention to detail, from intricate mechanisms to premium elements.

Wearing a Swiss watch is more than a way to check the hour. It signifies timeless elegance and exceptional durability.

Be it a bold statement piece, Swiss watches offer remarkable reliability that lasts for generations.

https://dungeonsofdwarfheim.com/phpbb/viewtopic.php?t=115391

JordanMah

Exquisite wristwatches have long been synonymous with precision. Expertly made by renowned watchmakers, they combine heritage with innovation.

Every component demonstrate unmatched quality, from precision-engineered calibers to luxurious materials.

Wearing a horological masterpiece is a true statement of status. It stands for refined taste and uncompromising quality.

No matter if you love a minimalist aesthetic, Swiss watches deliver remarkable reliability that lasts for generations.

https://abrikosnv.ru/guestbook

JordanMah

Swiss watches have long been a benchmark of excellence. Meticulously designed by legendary artisans, they seamlessly blend tradition with modern technology.

Each detail reflect unmatched attention to detail, from hand-assembled movements to premium elements.

Investing in a Swiss watch is a true statement of status. It represents sophisticated style and uncompromising quality.

Be it a minimalist aesthetic, Swiss watches offer remarkable precision that lasts for generations.

https://www.exceldashboardwidgets.com/phpBB3/viewtopic.php?t=1187

JordanMah

Exquisite wristwatches have long been synonymous with precision. Crafted by legendary artisans, they perfectly unite classic techniques with cutting-edge engineering.

Each detail embody superior quality, from precision-engineered calibers to luxurious materials.

Owning a timepiece is a true statement of status. It represents refined taste and heritage craftsmanship.

Whether you prefer a bold statement piece, Swiss watches provide remarkable beauty that never goes out of style.

http://sevenwater.square7.ch/bhearts/showthread.php?tid=449

JordanMah

Exquisite wristwatches have long been a benchmark of excellence. Expertly made by renowned watchmakers, they seamlessly blend tradition with innovation.

Each detail demonstrate unmatched workmanship, from hand-assembled movements to premium materials.

Owning a horological masterpiece is more than a way to check the hour. It represents refined taste and exceptional durability.

Be it a minimalist aesthetic, Swiss watches offer unparalleled reliability that lasts for generations.

https://www.opelteams.de/threads/which-watch-do-you-wear.1353/

JordanMah

Exquisite wristwatches have long been a gold standard in horology. Meticulously designed by renowned brands, they combine tradition with innovation.

All elements embody unmatched quality, from hand-assembled movements to luxurious finishes.

Wearing a Swiss watch is not just about telling time. It signifies sophisticated style and exceptional durability.

Be it a classic design, Swiss watches deliver remarkable beauty that stands the test of time.

http://forum.divlya.com/index.php?topic=283.new#new

JordanMah

Exquisite wristwatches have long been synonymous with precision. Expertly made by legendary watchmakers, they seamlessly blend classic techniques with modern technology.

All elements demonstrate superior quality, from hand-assembled movements to premium elements.

Investing in a horological masterpiece is not just about telling time. It signifies timeless elegance and uncompromising quality.

Be it a bold statement piece, Swiss watches provide remarkable reliability that never goes out of style.

https://prepperforum.se/showthread.php?tid=75342

JordanMah

Swiss watches have long been a gold standard in horology. Crafted by legendary artisans, they perfectly unite tradition with cutting-edge engineering.

Every component demonstrate superior quality, from precision-engineered calibers to luxurious finishes.

Wearing a Swiss watch is a true statement of status. It signifies refined taste and heritage craftsmanship.

Whether you prefer a bold statement piece, Swiss watches deliver extraordinary beauty that lasts for generations.

https://dungeonsofdwarfheim.com/phpbb/viewtopic.php?t=115391

JordanMah

Exquisite wristwatches have long been a benchmark of excellence. Crafted by legendary artisans, they perfectly unite heritage with innovation.

Every component embody exceptional workmanship, from precision-engineered calibers to premium finishes.

Wearing a horological masterpiece is more than a way to check the hour. It stands for refined taste and uncompromising quality.

Whether you prefer a bold statement piece, Swiss watches offer remarkable beauty that lasts for generations.

http://elitecad.pl/forum/viewtopic.php?f=20&t=913&p=549401#p549401

Bridgette

It’s truly very complicated in this active life to listen news on Television, thus

I only use world wide web for that purpose, and take the hottest information.

Look into my web page :: Ботокс в щеки

Sergio

An outstanding share! I have just forwarded this onto a co-worker who has been conducting a little research on this.

And he actually ordered me breakfast because I discovered it

for him… lol. So allow me to reword this….

Thanks for the meal!! But yeah, thanks for

spending the time to discuss this issue here on your site.

My web blog: Botox procedure for lips

Carey

What a data of un-ambiguity and preserveness of precious

familiarity regarding unexpected emotions.

Also visit my website … ботокс бровей

Fredrick

Hi there friends, its enormous post about educationand entirely defined, keep it

up all the time.

Also visit my website: free tv online

обязательная сертификация

Прохождение сертификации на территории РФ по-прежнему считается ключевым условием выхода продукции на рынок.

Этот процесс подтверждает соответствие установленным требованиям государственным стандартам и законам, что защищает покупателей от небезопасной продукции.

сертификация качества

Кроме того, наличие сертификатов способствует взаимодействие с крупными ритейлерами и расширяет конкурентные преимущества на рынке.

При отсутствии сертификатов, возможны проблемы с законом и сложности в процессе реализации продукции.

Поэтому, официальное подтверждение качества является не просто обязательным, но и важным фактором укрепления позиций компании на отечественном рынке.

BryanLed

Immerse yourself in the world of cutting-edge technology with the global version of the POCO M6 Pro, which combines advanced features, stylish design, and an affordable price. This smartphone is designed for those who value speed, quality, and reliability.

Why is the POCO M6 Pro your ideal choice?

– Powerful Processor: The octa-core Helio G99-Ultra delivers lightning-fast performance. Gaming, streaming, multitasking—everything runs smoothly and without lag.

– Stunning Display: The 6.67-inch AMOLED screen with FHD+ resolution (2400×1080) and a 120Hz refresh rate offers incredibly sharp and vibrant visuals. With a touch sampling rate of 2160 Hz, every touch is ultra-responsive.

– More Memory, More Possibilities: Choose between the 8/256 GB or 12/512 GB configurations to store all your files, photos, videos, and apps without compromise.

– Professional Camera: The 64 MP main camera with optical image stabilization (OIS), along with additional 8 MP and 2 MP modules, allows you to capture stunning photos in any conditions. The 16 MP front camera is perfect for selfies and video calls.

– Long Battery Life, Fast Charging: The 5000 mAh battery ensures all-day usage, while the powerful 67W turbo charging brings your device back to life in just a few minutes.

– Global Version: Support for multiple languages, Google Play, and all necessary network standards (4G/3G/2G) makes this smartphone universal for use anywhere in the world.

– Convenience and Security: The built-in fingerprint sensor and AI-powered face unlock provide quick and reliable access to your device.

– Additional Features: NFC, IR blaster, dual speakers, and IP54 splash resistance—everything you need for a comfortable experience.

The POCO M6 Pro is not just a smartphone; it’s your reliable companion in the world of technology.

Hurry and grab it at a special price of just 15,000 rubles! Treat yourself to a device that impresses with its power, style, and functionality.

Take a step into the future today—purchase it on AliExpress!

b2best.at

Теневой интернет — это анонимная зона онлайн-пространства, куда можно попасть только через специальные программы, например, Freenet.

В даркнете доступны как официальные, но и нелегальные платформы, среди которых магазины и различные сервисы.

Одной из крупнейших платформ считается Блэк Спрут, данный ресурс занималась торговле разных категорий, включая противозаконные продукты.

bs2best

Эти ресурсы довольно часто работают через криптовалюту в целях анонимности операций.

Тем не менее, спецслужбы время от времени ликвидируют популярные нелегальные рынки, однако вскоре открываются альтернативные торговые точки.

b2best.at

Darknet — это скрытая область интернета, куда открывается доступ исключительно через шифрованные соединения, например, Tor.

Здесь доступны как официальные, но и нелегальные платформы, среди которых магазины и другие сервисы.

Одной из известных онлайн-площадок является BlackSprut, данный ресурс специализировалась на реализации разных категорий, включая запрещенные продукты.

bs2best

Подобные площадки довольно часто функционируют на анонимные платежи для обеспечения анонимности операций.

Однако, спецслужбы периодически блокируют основные незаконные платформы, но взамен открываются другие площадки.

bs2beast.cc

Даркнет — это закрытая зона сети, куда можно попасть с использованием защищенные браузеры, например, через Tor.

В даркнете доступны как легальные, так и нелегальные ресурсы, среди которых форумы и различные платформы.

Одной из известных платформ является Блэк Спрут, что предлагала торговле различных товаров, включая нелегальные вещества.

bs2best актуальная ссылка

Такие площадки довольно часто работают через криптовалюту для повышения скрытности операций.

Тем не менее, правоохранительные органы регулярно блокируют основные незаконные платформы, хотя взамен открываются другие площадки.

bs2best.gdn

Даркнет — это скрытая область сети, куда открывается доступ исключительно через шифрованные соединения, например, Freenet.

В этой среде доступны как легальные, но и запрещенные сайты, среди которых форумы и другие платформы.

Одной из крупнейших платформ считается BlackSprut, что предлагала торговле разных категорий, в частности запрещенные вещества.

bs2best at сайт

Такие сайты довольно часто используют биткойны для обеспечения анонимности операций.

Однако, власти время от времени блокируют основные незаконные платформы, однако взамен появляются новые площадки.

b2best.at

Теневой интернет — это скрытая область интернета, куда открывается доступ исключительно через шифрованные соединения, например, через I2P.

Здесь можно найти как легальные, но и противозаконные сайты, например, магазины и другие площадки.

Одной из таких платформ является Блэк Спрут, что предлагала торговле разнообразной продукции, в частности противозаконные продукты.

https://bs2best

Такие сайты нередко работают через криптовалюту в целях конфиденциальности операций.

При этом, спецслужбы время от времени ликвидируют популярные незаконные платформы, но взамен возникают альтернативные площадки.

JasonmuB

We offer a comprehensive collection of trusted healthcare solutions to suit your health requirements.

Our platform ensures fast and reliable order processing to your location.

Each medication comes from certified suppliers so you get safety and quality.

Feel free to search through our catalog and get your medicines in minutes.

If you have questions, Our support team are here to help at any time.

Take care of yourself with our trusted medical store!

https://www.bawabetalquds.com/wall/blogs/8216/Aromasin-A-Powerful-Ally-in-Hormone-Related-Cancer-Therapy

bs2best.gdn

Darknet — это анонимная область интернета, куда можно попасть только через специальные программы, например, через Tor.

Здесь доступны официальные , например, магазины и различные площадки.

Одной из известных онлайн-площадок считается Блэк Спрут, что занималась продаже разных категорий.

bs2best актуальная ссылка

Эти сайты довольно часто работают через анонимные платежи для обеспечения конфиденциальности транзакций.

BryanLed

INCREDIBLY REALISTIC SEX DOLL WITH METAL SKELETON!

Feel the difference – just like a real partner!

ULTRA-SOFT SKIN that perfectly mimics the touch of real human skin – indistinguishable!

Anatomically accurate proportions, just like a real woman – every curve in perfect harmony!

WHY IS THIS DOLL EVERY MAN’S DREAM?

– FLEXIBLE METAL FRAME – holds any position you can imagine!

– 100% SAFE – non-toxic medical-grade material, certified by CCIC – no weird smells, just pure pleasure!

– MAXIMUM VERSATILITY – enjoy vaginal, anal, oral, breast play and anything else you desire!

– EASY MAINTENANCE – simple to keep clean and fresh!

EXCLUSIVE OFFER! Get yours now at the best price – while stocks last TOP-RATED Love Doll on AliExpress with RAVING REVIEWS!!

GET YOUR LUXURIOUS COMPANION NOW!

Discreet neutral packaging – 100% privacy guaranteed!

This isn’t just a doll – it’s the fulfillment of your deepest desires! Don’t miss out – **order now and experience ultimate pleasure!

bs2best.gdn

Даркнет — это закрытая область онлайн-пространства, доступ к которой с использованием специальные программы, например, Freenet.

Здесь можно найти официальные , включая магазины и прочие платформы.

Одной из крупнейших онлайн-площадок является Блэк Спрут, данный ресурс специализировалась на продаже различных товаров.

bs2best at сайт

Такие сайты довольно часто функционируют на криптовалюту в целях конфиденциальности операций.

JasonmuB

Our store provides a vast selection of trusted medicines for various needs.

Our online pharmacy ensures speedy and safe order processing wherever you are.

Every item is supplied by trusted suppliers so you get effectiveness and reliability.

Feel free to explore our selection and get your medicines in minutes.

Need help? Pharmacy experts will guide you whenever you need.

Prioritize your well-being with reliable medical store!

https://www.apsense.com/article/840402-when-and-why-doctors-prescribe-amoxil-1000-antibiotic.html

JasonmuB

You can find a wide range of high-quality pharmaceutical products to suit your health requirements.

This website ensures fast and reliable shipping wherever you are.

Each medication comes from trusted suppliers so you get safety and quality.

You can browse our online store and make a purchase in minutes.

Need help? Pharmacy experts are here to help whenever you need.

Stay healthy with reliable e-pharmacy!

https://www.linkcentre.com/review/www.imedix.com/pharmacy-reviews/alldaychemist-com/

JasonmuB

Our store provides a wide range of certified medicines for different conditions.

Our platform guarantees fast and secure delivery right to your door.

Each medication is sourced from certified suppliers to ensure safety and quality.

Easily explore our online store and place your order with just a few clicks.

Need help? Our support team is ready to assist you whenever you need.

Prioritize your well-being with reliable medical store!

https://www.bawabetalquds.com/wall/blogs/8185/Lasix-A-Lifesaving-Solution-for-Fluid-Retention-and-Heart-Health

JasonmuB

You can find a wide range of high-quality pharmaceutical products for various needs.

Our online pharmacy provides fast and secure delivery right to your door.

All products comes from certified suppliers to ensure effectiveness and reliability.

You can explore our catalog and get your medicines with just a few clicks.

Need help? Pharmacy experts are here to help at any time.

Take care of yourself with affordable e-pharmacy!

https://www.apsense.com/article/840403-understanding-amoxil-400-and-its-pediatric-use.html

JasonmuB

We offer a vast selection of trusted healthcare solutions for different conditions.

Our online pharmacy provides fast and reliable order processing right to your door.

Every item comes from trusted suppliers so you get safety and quality.

Feel free to browse our selection and make a purchase hassle-free.

If you have questions, Customer service will guide you at any time.

Stay healthy with reliable medical store!

https://pbase.com/imedix/image/174938037

JasonmuB

Our store provides a wide range of high-quality medicines to suit your health requirements.

This website provides quick and reliable order processing to your location.

All products is supplied by trusted manufacturers to ensure effectiveness and reliability.

Feel free to search through our catalog and place your order with just a few clicks.

Need help? Pharmacy experts will guide you at any time.

Take care of yourself with our trusted online pharmacy!

https://www.storeboard.com/blogs/health/how-deep-does-the-rabbit-hole-go/6086834

JasonmuB

You can find a wide range of certified pharmaceutical products for various needs.

Our online pharmacy ensures quick and safe order processing right to your door.

Every item comes from certified suppliers for guaranteed effectiveness and reliability.

You can browse our selection and get your medicines hassle-free.

If you have questions, Customer service will guide you at any time.

Prioritize your well-being with affordable online pharmacy!

https://www.debwan.com/blogs/598396/Small-Steps-and-Quiet-Victories-A-Journey-with-Sildenafil-at

JasonmuB

We offer a wide range of high-quality pharmaceutical products to suit your health requirements.

This website guarantees speedy and reliable order processing wherever you are.

All products is sourced from trusted pharmaceutical companies so you get effectiveness and reliability.

Feel free to explore our catalog and make a purchase in minutes.

Need help? Pharmacy experts will guide you whenever you need.

Prioritize your well-being with reliable medical store!

https://www.apsense.com/article/838693-the-deadly-balancing-act-the-truth-about-cenforce-dosage.html

JasonmuB

Our store provides a vast selection of high-quality healthcare solutions to suit your health requirements.

Our platform ensures speedy and safe delivery wherever you are.

Every item is supplied by certified suppliers to ensure effectiveness and reliability.

Easily browse our catalog and make a purchase hassle-free.

If you have questions, Our support team is ready to assist you 24/7.

Take care of yourself with our trusted online pharmacy!

https://www.apsense.com/article/841983-proscar-finasteride-the-complete-long-term-guide.html

JasonmuB

We offer a vast selection of high-quality pharmaceutical products for various needs.

Our online pharmacy provides fast and safe order processing right to your door.

Every item is sourced from trusted manufacturers to ensure safety and quality.

Feel free to search through our selection and get your medicines in minutes.

If you have questions, Pharmacy experts is ready to assist you at any time.

Stay healthy with our trusted e-pharmacy!

https://www.apsense.com/article/842008-long-term-priligy-use-the-shocking-truth-after-5-years.html

JasonmuB

Our store provides a comprehensive collection of high-quality healthcare solutions for various needs.

Our platform provides speedy and reliable order processing wherever you are.

Every item is supplied by certified suppliers so you get effectiveness and reliability.

Feel free to search through our online store and place your order hassle-free.

If you have questions, Pharmacy experts are here to help at any time.

Stay healthy with our trusted e-pharmacy!

https://www.storeboard.com/blogs/health/cenforce-150-mg-a-high-dose-solution-for-men-seeking-effective-ed-treatment/6071428

JasonmuB

Our store provides a vast selection of certified healthcare solutions for different conditions.

Our platform guarantees fast and safe shipping to your location.

Each medication is supplied by trusted pharmaceutical companies to ensure authenticity and compliance.

You can explore our online store and get your medicines hassle-free.

Need help? Customer service will guide you at any time.

Stay healthy with reliable medical store!

https://www.apsense.com/article/842230-acyclovir-online-the-ultimate-guide-to-safe-internet-purchases-of.html

JasonmuB

We offer a vast selection of trusted healthcare solutions for various needs.

Our online pharmacy provides speedy and reliable order processing wherever you are.

Each medication is supplied by licensed pharmaceutical companies so you get safety and quality.

Feel free to explore our selection and get your medicines hassle-free.

If you have questions, Customer service are here to help whenever you need.

Prioritize your well-being with our trusted online pharmacy!

https://www.apsense.com/article/835131-kamagra-100mg-understanding-its-strength-and-effectiveness.html

JasonmuB

We offer a vast selection of certified healthcare solutions to suit your health requirements.

This website provides quick and reliable shipping to your location.

Every item is sourced from trusted suppliers for guaranteed authenticity and compliance.

Easily browse our catalog and get your medicines in minutes.

Need help? Customer service will guide you 24/7.

Stay healthy with reliable online pharmacy!

https://www.apsense.com/article/841996-does-priligy-really-work-the-uncensored-truth-revealed.html

JasonmuB

We offer a wide range of high-quality medicines for various needs.

This website ensures speedy and secure shipping right to your door.

Each medication is sourced from licensed suppliers so you get authenticity and compliance.

Easily search through our online store and make a purchase hassle-free.

Need help? Customer service are here to help at any time.

Take care of yourself with our trusted e-pharmacy!

https://nichebase.xyz/vidalista-80-breaking-myths-about-ed-treatments/

JasonmuB

Our store provides a comprehensive collection of trusted medicines for different conditions.