The Role of Double-Headed Rotor Shafts in Motor Systems

Double-headed rotor shafts are essential components in motor systems, serving as critical links between the power source and the mechanical output. These shafts play a key role in maintaining the efficiency, precision, and reliability of various industrial and commercial machinery. With their unique design, they not only optimize power transmission but also improve the overall performance of motor-driven systems.

In this article, we explore the significance of double-headed rotor shafts, their key functions, applications across different industries, and the benefits of choosing high-quality shafts for your motor systems.

What is a Double-Headed Rotor Shaft?

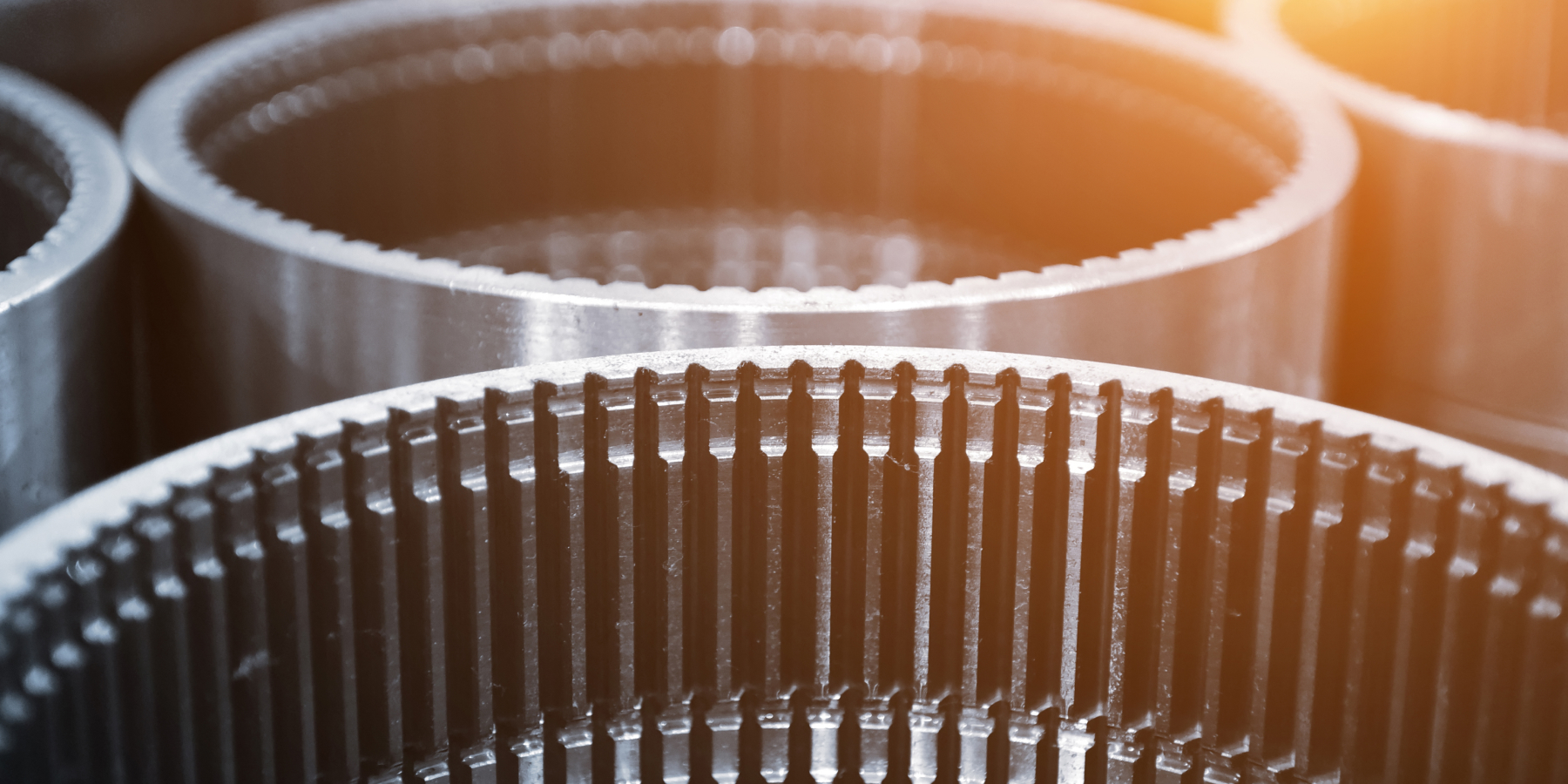

A double-headed rotor shaft is a specialized type of motor shaft that features two ends, or “heads,” designed to attach to multiple components in a motor system. This configuration allows it to efficiently transmit power, ensure balanced operation, and improve alignment between the motor and the driven equipment. Double-headed rotor shafts are commonly found in a variety of rotating machinery, including:

- Electric Motors

- Generators

- Turbines

- HVAC systems

The design of double-headed rotor shafts makes them ideal for applications that require enhanced precision, torque, and load handling. Their dual-end structure facilitates smoother power transmission and minimizes vibrations, which can extend the lifespan of the motor system.

Key Functions of Double-Headed Rotor Shafts

- Enhanced Torque Transmission:

One of the primary functions of double-headed rotor shafts is to transmit torque more efficiently. With their two-headed design, these shafts allow for smoother and more consistent power transfer between the motor and the components they drive. This ensures that the system operates with optimal efficiency, reducing energy loss and mechanical stress. - Improved Alignment:

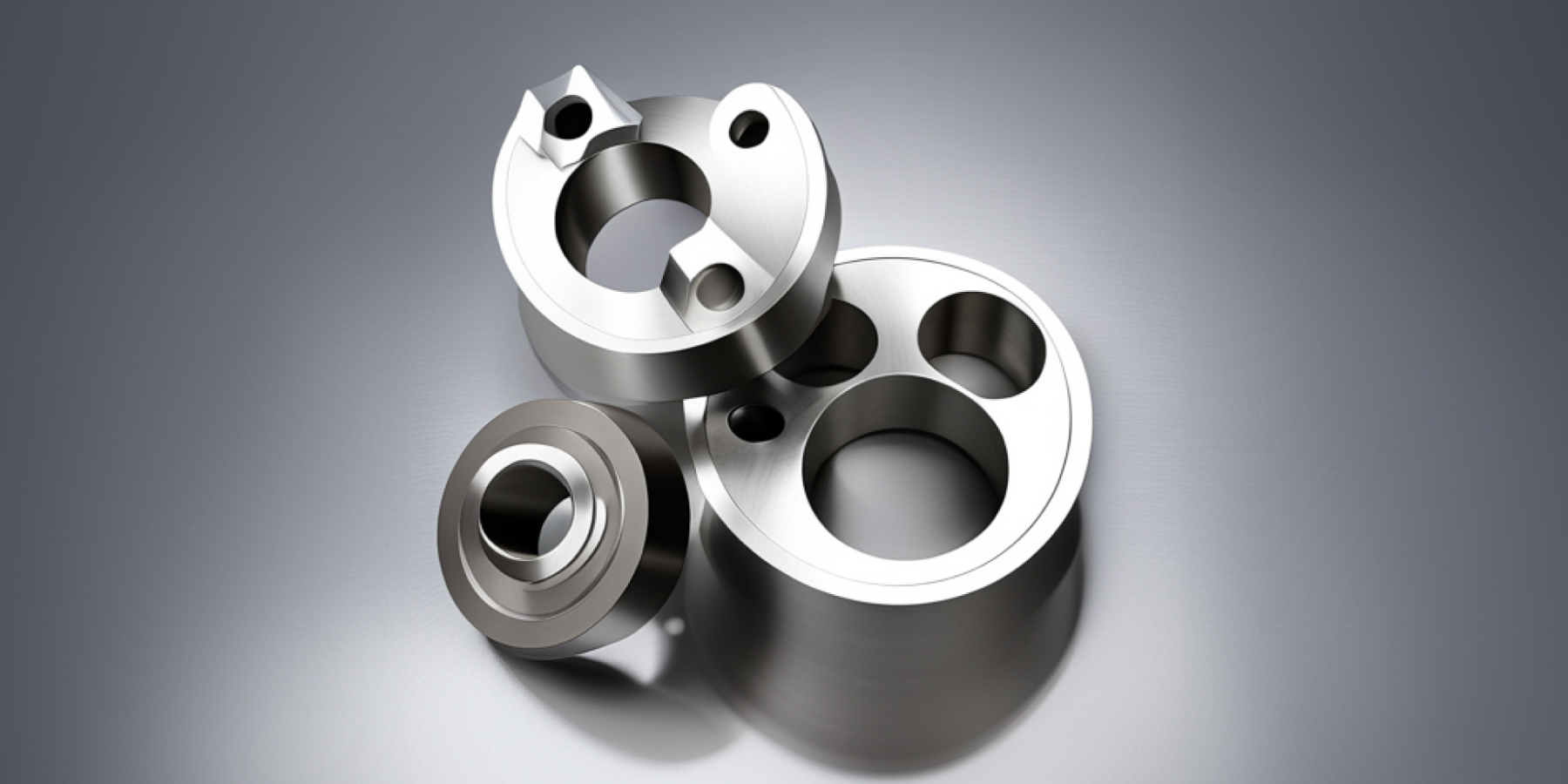

Double-headed rotor shafts are designed to improve alignment between the motor and the equipment it powers. Poor alignment can lead to excessive wear and tear, vibrations, and even system failure. By providing better alignment, these shafts help to minimize these risks, ensuring smoother operation and longer component life. - Durability and Strength:

Made from high-grade materials such as stainless steel, carbon steel, or specialized alloys, double-headed rotor shafts are built to withstand tough operating conditions. They offer high resistance to wear, corrosion, and mechanical fatigue, which is essential in demanding environments like manufacturing plants, energy systems, and automotive applications. - Vibration Reduction:

In rotating machinery, vibrations can lead to premature wear and component failure. The dual-head design of the rotor shaft helps to distribute forces evenly, reducing vibrations and enhancing the overall stability of the motor system.

5. Load-Bearing Capacity:

Double-headed rotor shafts are engineered to handle higher loads compared to traditional motor shafts. Their design allows for better load distribution, which is particularly useful in applications that involve heavy machinery or high-power motors.

Applications of Double-Headed Rotor Shafts in Motor Systems

Double-headed rotor shafts are versatile components used in various industries due to their ability to handle complex power transmission requirements. Below are some of the common applications:

- Industrial Motors:

In heavy machinery and industrial motors, double-headed rotor shafts are used to drive equipment such as compressors, pumps, and conveyor belts. These shafts ensure that the equipment runs smoothly under high torque and load conditions, making them essential for sectors like manufacturing, mining, and construction. - Automotive Applications:

In electric vehicles (EVs) and hybrid systems, double-headed rotor shafts are crucial for enhancing power transmission between the motor and the drivetrain. These shafts improve vehicle performance by providing efficient torque delivery, reducing wear on other components, and ensuring precise control of power flow. - Renewable Energy Systems:

Double-headed rotor shafts are also found in renewable energy applications such as wind turbines and hydroelectric generators. Their ability to handle high loads and maintain efficient power transmission is critical for the effective conversion of wind or water energy into electricity. The precision offered by these shafts helps to reduce energy loss and enhance the overall efficiency of the system.

4. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems rely on motor shafts to drive fans, blowers, and compressors. Double-headed rotor shafts in these systems ensure reliable operation by reducing misalignment, improving torque transmission, and minimizing mechanical stress.

Why Choose High-Quality Double-Headed Rotor Shafts?

Investing in high-quality double-headed rotor shafts can have a significant impact on the performance and longevity of your motor systems. Here are the key reasons why choosing superior-quality shafts is essential:

- Reduced Maintenance Costs:

By using durable materials and precise manufacturing processes, high-quality rotor shafts require less frequent maintenance and repairs. This can lead to substantial cost savings over the lifespan of the machinery, as components experience less wear and tear and operate more efficiently. - Increased Efficiency:

High-quality double-headed rotor shafts enhance torque transmission, reduce friction, and improve alignment, all of which contribute to better system efficiency. Improved efficiency can lead to lower energy consumption, reduced operational costs, and improved productivity. - Longer Lifespan:

Rotor shafts made from premium materials such as stainless steel or alloy steels are more resistant to corrosion, mechanical stress, and environmental factors. This durability results in a longer lifespan for the components, minimizing the need for frequent replacements and extending the operational life of the motor system.

4. Enhanced Precision and Performance:

Precision-engineered rotor shafts provide better alignment, reduced vibrations, and smoother operation, all of which contribute to enhanced performance. This is especially important in industries where precision and reliability are critical, such as aerospace, automotive, and energy production.

Conclusion

Double-headed rotor shafts are indispensable components in modern motor systems, offering enhanced torque transmission, improved alignment, and increased durability. Whether used in industrial motors, automotive applications, or renewable energy systems, these shafts play a critical role in optimizing system performance and ensuring long-term reliability.

By choosing high-quality double-headed rotor shafts, businesses can reduce maintenance costs, improve efficiency, and extend the life of their motor systems. If you’re looking to enhance your motor systems with top-tier double-headed rotor shafts, contact us today for expert guidance and a range of products tailored to meet your specific needs!

FAQs

A motor shaft refers to the component that connects the motor to the machinery it drives, typically transmitting torque to the system. A double-headed rotor shaft, on the other hand, has two ends designed for mounting, which improves torque transmission and alignment, offering advantages over traditional motor shafts in specific applications.

Double-headed rotor shafts are typically made from durable, high-strength materials such as stainless steel, carbon steel, or specialized alloys. These materials offer superior resistance to corrosion, wear, and mechanical stress, making the shafts suitable for demanding environments.

When selecting a double-headed rotor shaft, consider factors such as the torque requirements, operating conditions (temperature, load, and speed), material compatibility, and the dimensions of the shaft (length, diameter). Consulting with a supplier or engineer can help ensure that the shaft you choose meets your system's specific needs.