Valves, Pumps, Mounting Brackets, Forged Rings, and Kits for Industrial Excellence

Industrial processes rely on precision-engineered components like valves, pumps, mounting brackets, forged rings, and valve kits to ensure efficiency, durability, and safety. These components are integral to systems across industries such as oil and gas, chemical processing, power generation, and automotive engineering. This guide provides an overview of these essential components, their applications, and their benefits.

1. Valves and Pumps Components

Valve Components

Valves regulate the flow of fluids or gases in pipelines and systems, ensuring precise control, safety, and efficiency.

Key Components:

- Valve Bodies: The main pressure-retaining structure.

- Seats and Discs: Responsible for sealing and controlling flow.

- Stems and Actuators: Facilitate valve operation (manual or automated).

- Seals and Gaskets: Ensure leak-proof operation.

Applications:

- Oil and Gas: Used in pipelines, separators, and refineries.

- Chemical Processing: Manage corrosive fluids and high-pressure systems.

- Water Treatment: Regulate flow in filtration and distribution systems.

Benefits:

- Enhanced control and safety in critical applications.

- Long-lasting performance with corrosion-resistant materials like stainless steel.

Pump Components

Pumps transfer fluids or gases, playing a critical role in process systems.

Key Components:

- Impellers: Increase fluid velocity and pressure.

- Casing: Contains the fluid and directs its flow.

- Bearings and Seals: Minimize friction and prevent leaks.

- Shafts and Couplings: Transmit power from the motor to the pump.

Applications:

- Power Plants: Circulate cooling water and manage condensate systems.

- Food and Beverage: Ensure hygienic fluid transfer.

- Marine Engineering: Pump seawater and manage ballast systems.

Benefits:

- Efficient fluid transfer with reduced energy consumption.

- Reliable operation in high-pressure and high-temperature environments.

2. Mounting Brackets and Extension Bonnets

Mounting Brackets

Mounting brackets are used to secure equipment such as valves, actuators, or motors to a stable base.

Applications:

- Support for valve and actuator assemblies in industrial systems.

- Mounting components in automotive, HVAC, and machinery setups.

Benefits:

- Ensures stability and alignment of components.

- Reduces vibration and wear on connected systems.

Extension Bonnets

Extension bonnets are used with valves to insulate critical components from extreme temperatures or corrosive environments.

Applications:

- Cryogenic systems: Extend the stem away from cold fluids to prevent freezing.

- High-temperature applications: Protect seals and actuators from heat.

Benefits:

- Prolong valve life by reducing exposure to extreme conditions.

- Enhances operational reliability in harsh environments.

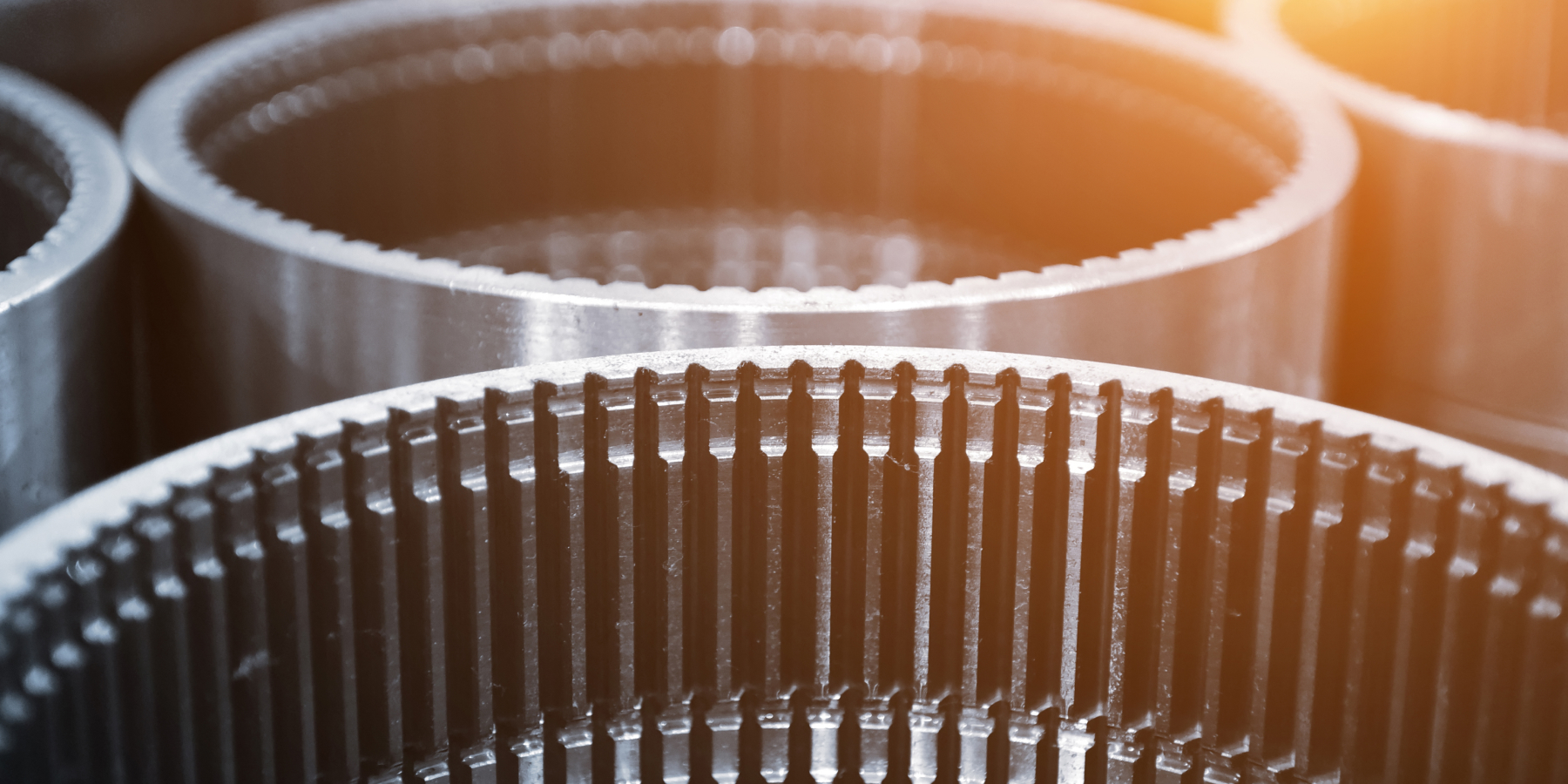

3. Forged Rings

Forged rings are integral to heavy-duty applications requiring strength and durability. They are manufactured by heating and compressing metal billets into seamless rings.

Types of Forged Rings

- Forged Steel Rings: Ideal for high-stress and high-temperature environments.

- Aluminum Forged Rings: Lightweight yet strong, suitable for aerospace and automotive applications.

- Customized Rings: Tailored to meet specific dimensions and performance needs.

Applications:

- Aerospace: Used in jet engines, turbines, and structural components.

- Automotive: Wheel hubs, gear rings, and bearing components.

- Oil and Gas: Flanges, connectors, and seals in pipelines.

- Power Generation: Turbine and boiler components.

Benefits:

- Superior tensile and impact strength.

- Long-lasting performance with minimal maintenance.

- Seamless construction ensures uniform strength and reliability.

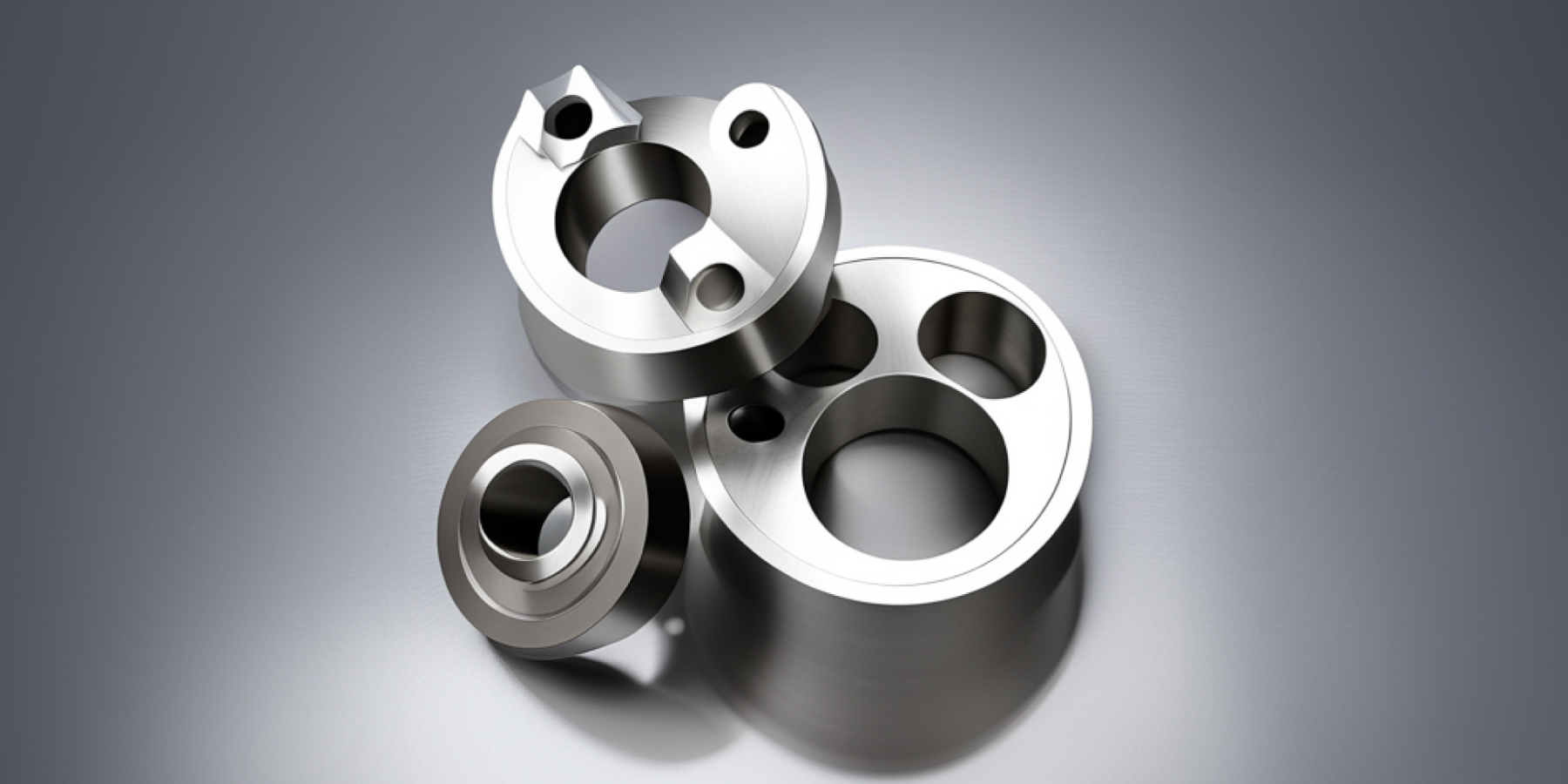

4. Valve Kits

Valve kits include a set of components for valve maintenance, repair, or performance enhancement.

Key Components of Valve Kits

- Valves (intake and exhaust): Ensure proper flow and sealing.

- Valve Seals: Prevent oil leaks into the combustion chamber.

- Springs and Retainers: Maintain proper valve movement and alignment.

- Guides and Seats: Provide stability and ensure efficient operation.

Benefits of Stainless Steel Engine Valves

- Corrosion Resistance: Resists rust and oxidation, prolonging valve life.

- High-Temperature Performance: Maintains integrity in combustion engines.

- Durability: Withstands mechanical stress and wear, ideal for high-mileage engines.

- Enhanced Efficiency: Provides smooth operation and better sealing for optimized engine performance.

Applications:

- Automotive Engines: Improves power, efficiency, and reliability.

- Industrial Machinery: Ensures long-lasting valve performance in harsh conditions.

- Marine Engines: Offers superior corrosion resistance in saltwater environments.

Selecting the Right Components for Your Application

Factors to Consider:

- Material Compatibility:

- Choose stainless steel or high-grade alloys for corrosive environments.

- Opt for lightweight materials like aluminium for weight-sensitive applications.

- Application Requirements:

- Consider operating temperature, pressure, and environmental conditions.

- Manufacturer Expertise:

- Partner with trusted suppliers offering certified and customizable solutions.

Optimize Your Industrial Systems with Premium Components

Looking for high-quality valves, pumps, mounting brackets, forged rings, or valve kits? Our precision-engineered products ensure durability, efficiency, and reliability for a wide range of industrial applications. [Contact us today for expert advice and a custom quote.]

FAQs

Stainless steel, brass, bronze, and high-temperature alloys are commonly used for their strength and corrosion resistance.

Forged rings have a seamless grain structure, offering superior strength, durability, and resistance to stress compared to cast rings.

Extension bonnets protect critical valve components from extreme temperatures or corrosive environments, enhancing their lifespan and reliability.

Stainless steel valves resist corrosion, handle high temperatures, and provide superior durability, making them ideal for high-performance and long-lasting engine applications.