What You Need to Know About The Role of Steel Rings in Industrial Applications

Steel rings play a critical role in many industrial applications, from machinery and engines to heavy-duty manufacturing processes. These durable, high-strength components offer several benefits, including excellent resistance to wear and corrosion. In this blog, we’ll explore the key benefits of steel rings, their versatile use in various industries, and why they are an indispensable part of modern industrial processes.

Why Steel Rings are Vital for Industrial Applications

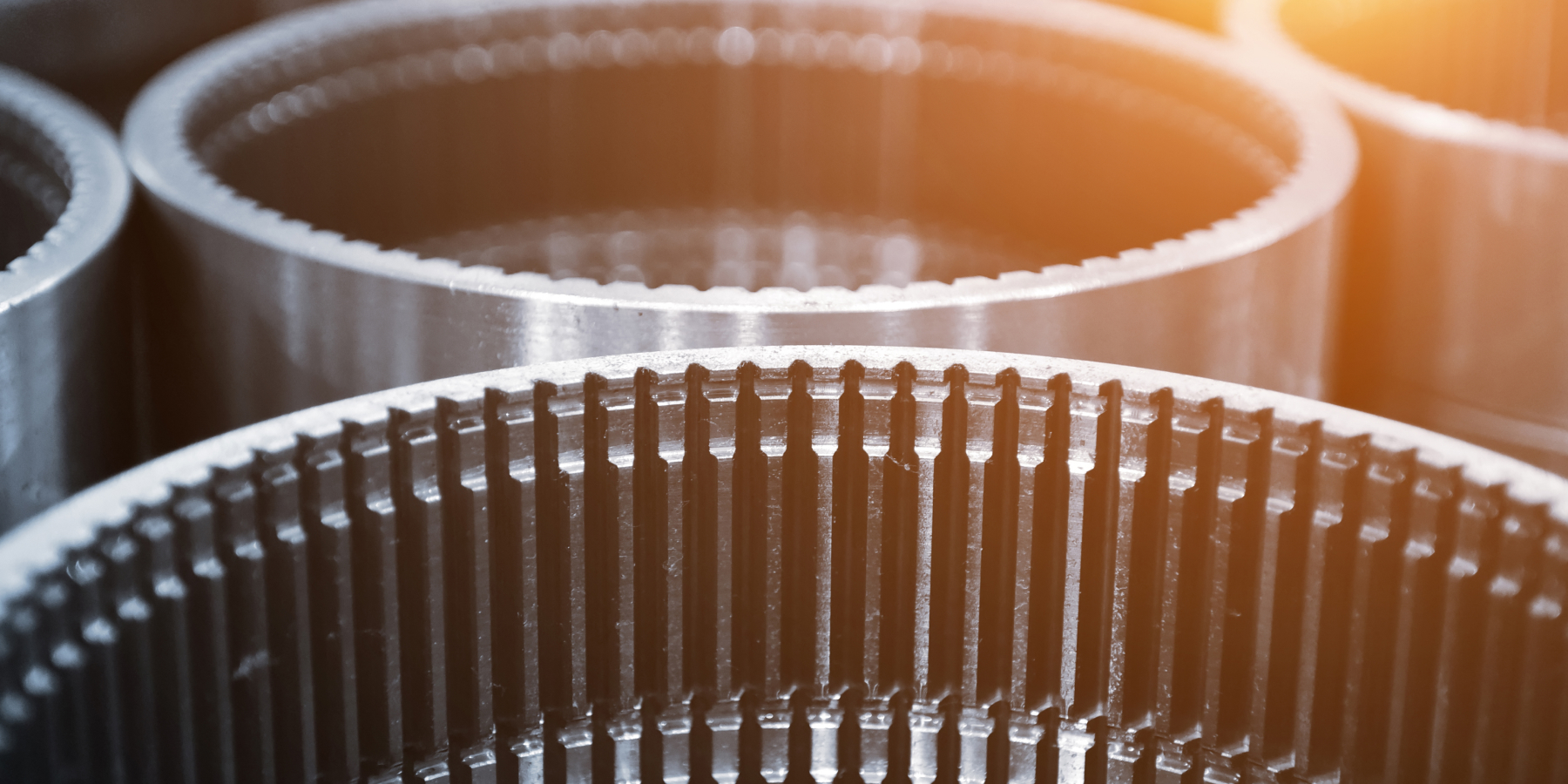

Steel rings are essential in industrial settings due to their robustness and long-lasting performance. They are commonly used in engines, turbines, valves, and compressors, where they endure extreme stress and high temperatures. The precision engineering behind steel rings ensures they fit seamlessly into mechanical systems, reducing the likelihood of mechanical failure and extending the equipment’s lifespan.

Key Benefits of Steel Rings

1. Durability and Strength

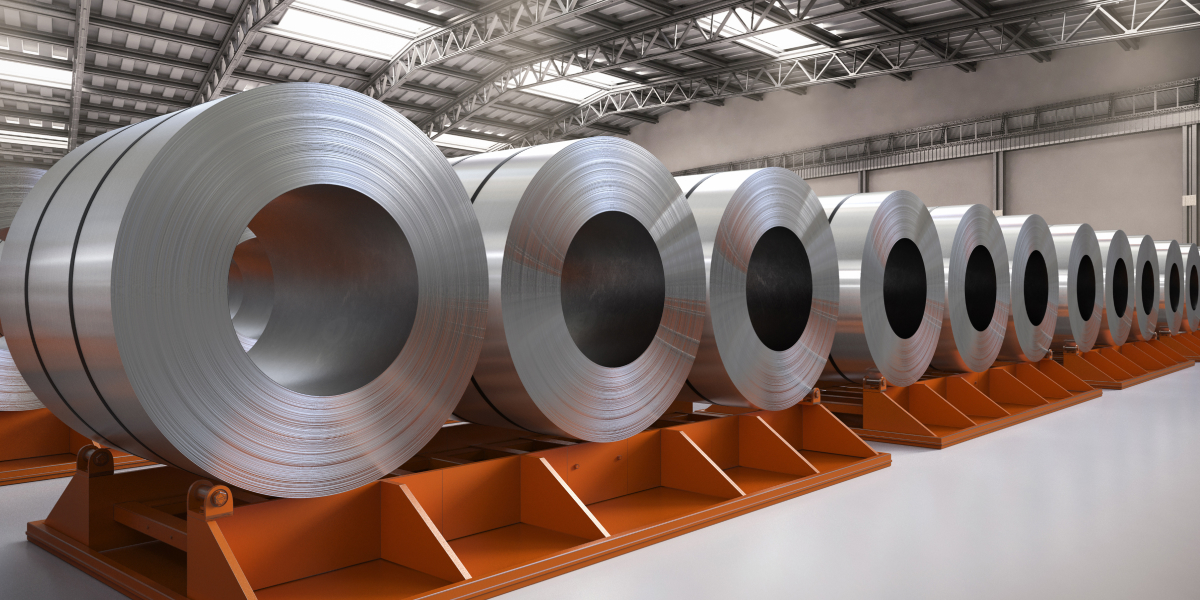

One of the primary benefits of steel rings is their unmatched durability. Made from high-grade materials, they can withstand immense pressure and friction, making them ideal for heavy-duty industrial applications.

2. Corrosion Resistance

Industries such as oil and gas, marine, and chemical processing face harsh environments where components are exposed to corrosive substances. Steel rings are resistant to rust and corrosion, ensuring longevity even in challenging environments.

3. Precision and Performance

Precision in the design and manufacturing of steel rings is vital to ensure proper alignment and functionality within industrial equipment. High-quality steel rings maintain tight tolerances, reducing wear and enhancing performance.

4. Cost-Efficiency

While steel rings offer high durability, they are also cost-effective. Their ability to last longer and reduce downtime in machinery leads to lower maintenance costs, which is critical for industries focused on optimizing operational efficiency.

Industrial Applications of Steel Rings

1. Automotive and Aerospace

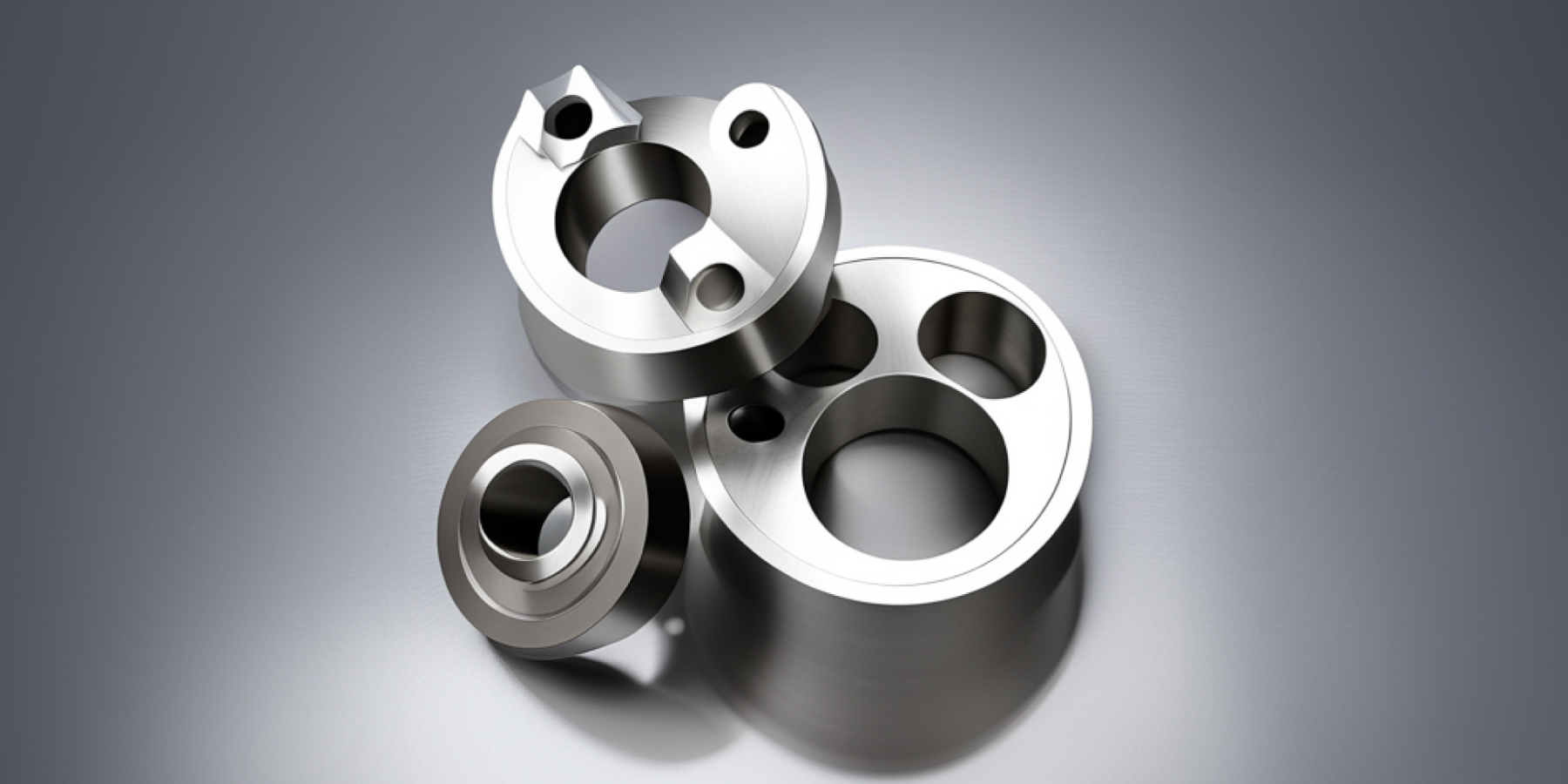

Steel rings are used in engines, transmissions, and braking systems in the automotive and aerospace industries. Their ability to withstand high temperatures and extreme forces makes them an indispensable component in ensuring vehicle and aircraft reliability.

2. Oil and Gas Industry

In oil drilling rigs and pipelines, steel rings provide seals that prevent leaks and ensure the integrity of the entire system. Their resistance to harsh chemicals and high pressure makes them a critical part of oil and gas exploration and refining processes.

3. Manufacturing and Heavy Machinery

In heavy machinery, steel rings are used to support shafts, pistons, and other moving parts. Their durability reduces wear, ensuring that equipment operates smoothly for longer periods with minimal maintenance.

4. Power Generation

In turbines and other power generation equipment, steel rings play a crucial role in maintaining efficiency and preventing equipment breakdown. Their precision and resistance to corrosion help extend the lifespan of critical components in power plants.

Choosing the Right Steel Rings for Your Industrial Needs

When selecting steel rings for industrial applications, consider the specific requirements of your equipment and operating environment. Factors such as temperature resistance, corrosion resistance, and load-bearing capacity are critical. Additionally, working with a trusted supplier ensures that the steel rings you receive are manufactured to the highest quality standards.

Conclusion

Steel rings are integral components in many industrial applications, providing strength, durability, and precision. Whether used in automotive engines, oil rigs, or manufacturing plants, the benefits of steel rings ensure that industrial equipment operates efficiently and with minimal downtime. By understanding their role and selecting the right steel rings for your needs, you can enhance the performance and longevity of your machinery, saving time and costs in the long

FAQs

Steel rings are widely used in industries like automotive, aerospace, oil and gas, power generation, and manufacturing. Their durability and resistance to extreme conditions make them ideal for high-stress applications.

Corrosion resistance is crucial for steel rings used in harsh environments, such as oil rigs and chemical processing plants. It ensures longevity and reliability, preventing equipment failure due to rust and wear, which is critical for safety and operational efficiency.

Steel rings enhance the performance of industrial machinery by maintaining tight tolerances, reducing wear on components, and preventing mechanical failures. Their durability and precision reduce the need for frequent maintenance, ensuring smoother and longer-lasting operation.